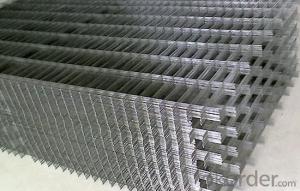

Welded Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Wire diameter bias maximum | Model Number: | |||

| Type: | Application: | Hole Shape: | |||

| Aperture: | Material: | Wire Gauge: | |||

| Surface Treatment: | Weave Type: | Certificates: | |||

| Aperture bias maximum:: | : | |

Packaging & Delivery

| Packaging Detail: | 50-100 pcs into a bundle on a pallet,with plastic film inside |

| Delivery Detail: | 15-25days depend on the final order quantity |

Specifications

1.ISO9001:2008,SGS,BV,CE,etc

2.12 years Factory

3.For fixing heating pipe,reinforcing concrete construction,etc

4,Galvanized

Wire Diameter(mm) | Aperture | Width(mm) | Length | |

Inch | mm | |||

2.0mm-3.2mm | 1" | 25.4 | 1200-2400 | The length does not limit |

2.0mm-4.5mm | 2" | 50.8 |

| |

2.0mm-6.0mm | 3" | 70.2 | 0.914m-2.75m | |

2.0mm-6.0mm | 4" | 101.6 | 0.914m-2.75m | |

2.0mm-6.0mm | 5" | 127 | 0.914m-2.75m | |

2.0mm-6.0mm | 6" | 152.4 | 0.914m-2.75m | |

2.0mm-6.0mm | 7" | 177.8 | 0.914m-2.75m | |

2.0mm-6.0mm | 8" | 203.2 | 0.914m-2.75m | |

- Q: Can steel wire mesh be used for decorative panels?

- Yes, steel wire mesh can definitely be used for decorative panels. Steel wire mesh offers a versatile and modern aesthetic that can complement various architectural styles and design preferences. It can be used to create unique patterns, textures, and visual effects, making it a popular choice for decorative applications such as interior and exterior wall panels, room dividers, stair railings, and furniture accents. Steel wire mesh is available in different gauges and mesh sizes, allowing for customization and flexibility in design. It can be woven or welded, providing different options for achieving specific decorative effects. Additionally, steel wire mesh can be coated or finished in various colors and textures, further enhancing its decorative potential. Aside from its aesthetic appeal, steel wire mesh also offers practical benefits. It is durable, strong, and resistant to corrosion, making it suitable for both indoor and outdoor use. It can be easily installed and maintained, ensuring longevity and functionality in decorative panel applications. Overall, steel wire mesh is a versatile material that can be used creatively to achieve decorative panels that add a touch of elegance, modernity, and uniqueness to any space.

- Q: Is steel wire mesh resistant to chemicals used in water treatment?

- Generally, steel wire mesh is resistant to the chemicals commonly used in water treatment. It is typically made from stainless steel, which offers excellent chemical resistance. It can resist corrosion and withstand exposure to various chemicals, including chlorine, fluorine, and different acids used in water treatment. Due to this, steel wire mesh is a suitable choice for filtration, separation, and reinforcement in water treatment plants. However, it is important to note that the resistance of the wire mesh to specific chemicals can be influenced by the type and grade of stainless steel used. Therefore, it is advisable to consult the manufacturer or supplier to ensure compatibility with the specific chemicals used in the water treatment process.

- Q: What are the cost considerations when using steel wire mesh?

- When using steel wire mesh, there are several cost considerations that need to be taken into account. Firstly, the cost of the steel wire mesh itself is an important factor. The price of steel wire mesh can vary depending on the type of steel used, the size and thickness of the mesh, and the specific requirements of the project. It is important to compare prices from different suppliers to ensure you are getting the best value for your money. Additionally, installation costs should be considered. Steel wire mesh typically requires professional installation, especially for larger or more complex projects. The cost of labor and any necessary equipment should be factored into the overall cost. Maintenance and durability are also important cost considerations. Steel wire mesh is known for its strength and durability, but it may require periodic maintenance to ensure its longevity. This can include cleaning, rust prevention, and repairs if any damage occurs. The cost of these maintenance activities should be taken into account when considering the overall cost of using steel wire mesh. Furthermore, transportation costs should be considered. Steel wire mesh can be heavy and bulky, which may increase transportation costs, especially if the project requires a large quantity of mesh. It is important to factor in the cost of shipping or transporting the mesh to the project site. Lastly, it is worth considering the long-term cost benefits of using steel wire mesh. While the initial cost may be higher compared to other materials, steel wire mesh's durability and strength can result in long-term cost savings. It can reduce the need for frequent replacements or repairs, potentially saving money in the long run. In conclusion, the cost considerations when using steel wire mesh include the price of the mesh itself, installation costs, maintenance and durability, transportation costs, as well as the potential long-term cost benefits. Taking all these factors into account will help in making an informed decision about using steel wire mesh for any project.

- Q: How is steel wire mesh used in the oil and gas industry?

- The oil and gas industry extensively employs steel wire mesh for a wide range of purposes, thanks to its exceptional strength, durability, and resistance to corrosion. Filtration systems represent a primary use case for steel wire mesh. It is commonly utilized as a filtering medium to eliminate solid impurities and contaminants from fluids like crude oil, natural gas, and drilling mud. The mesh size and porosity can be tailored to meet specific filtration requirements, ensuring the effective separation of particles and solids. Moreover, steel wire mesh finds application in reinforcing structures during oil and gas well drilling. It is employed to fortify concrete elements, such as well casings and platforms, which contributes to their stability and prevents potential collapse. In these instances, the mesh functions as a reinforcement material, elevating the structural integrity and longevity of the drilling infrastructure. Additionally, steel wire mesh plays a crucial role in constructing oil and gas pipelines. It serves as a protective layer, guarding against soil erosion and stabilizing the surrounding terrain. The mesh acts as a barrier, impeding the migration of soil particles and guaranteeing the pipeline's stability. Furthermore, it can deter animal burrowing and vegetation growth, minimizing the risk of pipeline damage. In offshore drilling operations, steel wire mesh is utilized as a safety measure. It is frequently employed as a safety barrier or fencing on platforms and walkways to prevent accidental falls. The mesh creates a secure boundary while allowing for visibility and ventilation. All in all, steel wire mesh boasts immense significance within the oil and gas industry, contributing to filtration, reinforcement, pipeline protection, and safety. Its versatility, strength, and ability to withstand harsh conditions make it an ideal choice for various applications in this field.

- Q: Is steel wire mesh suitable for use in rooftop gardens?

- Yes, steel wire mesh is suitable for use in rooftop gardens. Steel wire mesh is a versatile and durable material that can be used in various applications, including in rooftop gardens. It provides several benefits that make it a suitable choice for this purpose. Firstly, steel wire mesh is strong and able to withstand the weight of soil, plants, and other garden elements. This is important in rooftop gardens, where the structure needs to support the additional load without compromising safety and stability. Furthermore, steel wire mesh is resistant to weather conditions and can withstand exposure to sunlight, rain, and wind. This ensures that it remains sturdy and functional over time, making it an ideal choice for rooftop gardens that are exposed to the elements. Another advantage of steel wire mesh is its ability to provide support for climbing plants. It can be installed vertically to create trellises or frames for plants to grow and climb on, adding an aesthetic appeal to the garden. Moreover, steel wire mesh is a cost-effective option compared to other materials commonly used in rooftop gardens, such as wooden frames or concrete structures. It is also easy to install and maintain, making it a convenient choice for rooftop garden projects. In conclusion, steel wire mesh is suitable for use in rooftop gardens due to its strength, durability, weather resistance, support for climbing plants, and cost-effectiveness. It provides a solid foundation for rooftop gardens and contributes to their overall functionality and aesthetics.

- Q: Is steel wire mesh suitable for electrical grounding?

- Yes, steel wire mesh is suitable for electrical grounding. Steel wire mesh is a conductive material that can effectively carry electrical currents and provide a low resistance path for the dissipation of electrical charges. It can be used as an effective grounding system to protect against electrical shocks and ensure the safety of electrical equipment and personnel. However, it is important to ensure that the steel wire mesh is properly installed, connected, and bonded to the grounding system to ensure effective electrical grounding.

- Q: What are the benefits of using steel wire mesh in the telecommunications manufacturing industry?

- The utilization of steel wire mesh in the telecommunications manufacturing industry brings forth numerous advantages. To begin with, steel wire mesh boasts exceptional strength and durability. It possesses the ability to withstand even the harshest environmental conditions and remains resistant to corrosion, making it an ideal choice for installations in outdoor settings. This unrivaled strength and durability guarantee the integrity and reliability of the telecommunications infrastructure, thereby reducing the necessity for frequent repairs or replacements. Furthermore, steel wire mesh offers unparalleled protection and security. It serves as a physical barrier, effectively preventing unauthorized access to sensitive equipment and infrastructure. This serves to safeguard the telecommunications network against acts of vandalism, theft, or any other malicious activities, thus guaranteeing uninterrupted communication services. Additionally, steel wire mesh provides superb electromagnetic shielding properties. It effectively blocks electromagnetic interference (EMI) and radio frequency interference (RFI). This shielding capability holds immense importance in the telecommunications industry as it ensures the maintenance of signal quality and prevents disruptions or distortions in communication. Moreover, steel wire mesh exhibits great versatility and can be easily tailored to meet specific requirements. It can be manufactured in a plethora of sizes, shapes, and configurations to cater to different applications, including cable trays, enclosures, or fencing. This flexibility enables telecommunications manufacturers to design and construct infrastructure solutions that perfectly align with their needs. Lastly, steel wire mesh presents a cost-effective solution. Its extended lifespan and minimal maintenance requirements result in reduced operational expenses over the long run. Additionally, its recyclability makes it an environmentally friendly choice that aligns with sustainability objectives. In summary, the utilization of steel wire mesh in the telecommunications manufacturing industry offers a wide array of benefits, including unmatched strength and durability, unparalleled protection and security, superb electromagnetic shielding, exceptional versatility, and cost-effectiveness. These advantages position it as the ideal material for constructing reliable and secure telecommunications infrastructure.

- Q: Can steel wire mesh be used for privacy partitions?

- Yes, steel wire mesh can be used for privacy partitions. Steel wire mesh is a durable and versatile material that can be used to create visually appealing partitions while still maintaining privacy. It can be installed in various settings such as gardens, outdoor areas, or even indoor spaces. The mesh size and thickness can be chosen to suit the level of privacy required. Additionally, steel wire mesh can be combined with other materials such as wood or glass to create a more aesthetically pleasing and functional privacy partition. Overall, steel wire mesh is a great option for those looking to create privacy partitions that are both durable and stylish.

- Q: Can steel wire mesh be used in high-temperature environments?

- Yes, steel wire mesh can be used in high-temperature environments. Steel wire mesh is known for its high heat resistance and durability, making it suitable for applications that involve exposure to extreme temperatures. The material used in steel wire mesh, typically stainless steel or other heat-resistant alloys, can withstand high temperatures without melting, deforming, or losing its structural integrity. This makes steel wire mesh a reliable choice for various industries, including aerospace, automotive, construction, and manufacturing, where it is commonly used for filtration, reinforcement, protection, and separation purposes in high-temperature environments. Additionally, steel wire mesh can also resist corrosion, making it a versatile option for both hot and corrosive environments. However, it is essential to consider the specific temperature range and other environmental factors when selecting the appropriate steel wire mesh type to ensure its optimum performance and longevity.

- Q: Can steel wire mesh be used for air vents?

- Yes, steel wire mesh can be used for air vents. Steel wire mesh is a versatile material that can effectively prevent the entry of larger debris, insects, and animals while allowing air to flow through. It is commonly used in air vents to provide ventilation and maintain proper airflow in various applications such as HVAC systems, industrial facilities, and residential homes. The durability and strength of steel wire mesh make it an ideal choice for air vents as it can withstand harsh weather conditions, resist corrosion, and provide long-lasting performance. Additionally, steel wire mesh can be easily customized to fit different shapes and sizes of air vents, ensuring a secure and efficient ventilation system.

Send your message to us

Welded Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords