Reinforced Steel Mat/Erosion Control Mat for Slope Reinforcement Project

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3D Reinforced Erosion Control Mat/Steel Mat Introduction

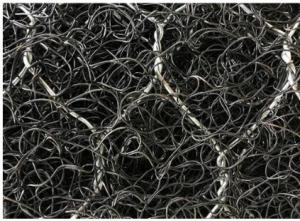

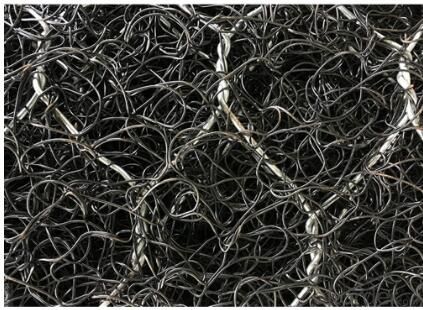

Erosion control is an integrated composite of high-tensile steel mesh and a three dimensional mat of PP monofilaments.

The combination of these two unique meshes results in a geomat which is very simple and fast to install and provides an optimal basis for the re-vegetation

of bare areas.

This synthetic material combines the perfect corrosion resistance of geomats, it has higher mechanical tension force and stronger erosion resistance.

3D Reinforced Erosion Control Mat/Steel Mat Introduction Property

1) Self permeability, the gap of erosion control is helpful to discharge of water from the structure, meanwhile, relevant cost of drainage equipment for traditional structure is saved.

2) Stereo vegetability, the stereoscopic properties can greatly enhance the growth space of plants, natural exchange of water and soil is realized. Increasing greening area, and realizing flexible slope protection.

3) Long service life, its raw material is 10% Aluminum-Zinc Alloy Steel Wire, with stronger corrosion resistance, it can guarantee its service life. Stable performance, ultraviolet resistance, acid and alkali corrosion resistance, abrasion resistance.

4) Easy to installation, simple operation, less disturbance by climate and suitable for mechanized operation can ensure construction quality and speed up construction progress.

3D Reinforced Erosion Control Mat/Steel Mat Introduction Data Sheet

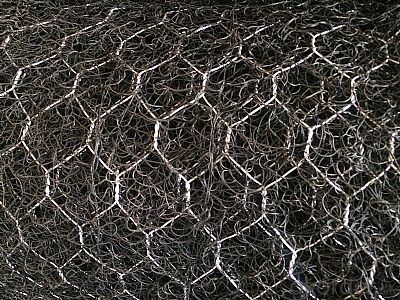

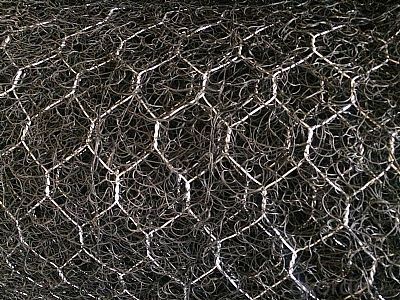

Item | Diameter | Mesh Size | Tensile Strength(MD) | Tensile Strength(CD) | Edge wire tensile strength | The intensity of coating |

Steel Mesh | 2.7mm | 80*100mm | 26KN/M | 51KN/M | 20KN/M | 87KN/M |

Item | Melting Point | Void Index | Polymer | Weight | Anit-UV |

Geomat | 150 | ≥90% | Polypropylene | 400g/m2 | Stable |

3D Reinforced Erosion Control Mat/Steel Mat Introduction Application

a) Public / railway embankment, embankment, cutting, bridge abutments

b) Landslides, mudslides and control engineering

c) Inland port, coastal protection, urban construction of retaining structures, river training works

- Q: How do earthwork products contribute to land reclamation projects?

- Earthwork products play a crucial role in land reclamation projects by providing essential materials for shaping the land and creating desired topography. These products, such as soil, sand, gravel, and rocks, are used to fill in low-lying areas, build up elevations, and stabilize the land. They help to reshape the terrain, create new landforms, and restore the natural balance of the reclaimed land. Additionally, earthwork products also aid in improving drainage systems and preventing erosion, ensuring the long-term sustainability of the reclaimed area.

- Q: In addition to cement, but also add gelling agent

- The role of adding gelling agent in cement mortar is to enhance the adhesion

- Q: What are the classification of civil engineering graduate students?

- The main technical courses and specialized courses are: material mechanics, structural mechanics, fluid mechanics, computer science, computer language and procedures, computer aided design, civil engineering materials, engineering drawings, engineering geology and survey, surveying, soil mechanics and foundation Architecture, concrete structure and masonry structure, steel structure, construction technology and organization, construction project management, structural seismic design and related major specialized courses.

- Q: What is the purpose of using geotextile mats in road construction?

- The purpose of using geotextile mats in road construction is to enhance the stability, durability, and performance of the road. These mats act as a barrier between the subgrade soil and the overlying layers, preventing the mixing of different materials and reducing the potential for soil erosion. Geotextile mats also help in distributing the load evenly across the road surface, preventing the formation of cracks and potholes. Additionally, they improve drainage, reduce water infiltration into the road layers, and provide reinforcement to the road structure, thereby extending its lifespan.

- Q: How are geotextile tubes used in sediment control during harbor dredging?

- Geotextile tubes are commonly used in sediment control during harbor dredging by acting as containment structures for the dredged material. They are filled with the dredged sediment and then positioned strategically to create temporary dikes or barriers, preventing the sediments from dispersing into the surrounding water. The tubes' permeable fabric allows water to exit while retaining the sediment, effectively controlling erosion and maintaining water quality during the dredging process.

- Q: What are the advantages of using geotextile tubes for shoreline protection?

- Geotextile tubes offer several advantages for shoreline protection. Firstly, they are cost-effective compared to traditional methods such as concrete or rock revetments. They are also easy to install and can be filled on-site with locally available materials, reducing transportation costs. Geotextile tubes are flexible, allowing them to conform to irregular shorelines and absorb wave energy, thereby reducing erosion. Moreover, they are environmentally-friendly as they can be filled with sediment, promoting habitat restoration and creating natural buffers against storms. Lastly, geotextile tubes are durable and can withstand harsh weather conditions, providing long-lasting protection for shorelines.

- Q: What is the civil engineering project?

- To study English, freshman sophomore to learn English, but also a professional English class, but the examination is very easy, and construction, mechanics that is sure to learn, and concrete design, a variety of mechanics, measurement, room open , High number, history, Mao, Mark

- Q: How are earthwork products different from regular construction materials?

- Earthwork products, such as soil, rocks, and gravel, are natural materials that are extracted from the earth's surface and used in construction projects. In contrast, regular construction materials, like bricks, concrete, and steel, are manufactured or processed materials that are specifically designed for construction purposes. The key difference lies in the origin and composition of these materials, as well as their production methods. Earthwork products are generally more cost-effective, readily available, and environmentally friendly, while regular construction materials offer greater structural strength and specific properties tailored to meet construction requirements.

- Q: How do geosynthetic panels help in land reclamation projects?

- Geosynthetic panels are instrumental in land reclamation projects as they provide effective erosion control, soil stabilization, and reinforcement. These panels prevent soil erosion by acting as a barrier against water flow and wind, allowing vegetation to establish and thrive. They also enhance the stability of the reclaimed land by distributing the load and reducing settlement, especially in areas with poor soil conditions. Moreover, geosynthetic panels improve the overall integrity of reclaimed land, ensuring long-term sustainability and successful land restoration.

- Q: Can earthwork products be used in groundwater protection projects?

- Yes, earthwork products can be used in groundwater protection projects. These products, such as geotextiles or geomembranes, are commonly used to create barriers and liners that prevent contaminants from reaching groundwater sources. They can also be utilized in erosion control measures to prevent soil erosion and the migration of pollutants. Earthwork products provide effective solutions for protecting and preserving groundwater quality in various environmental projects.

Send your message to us

Reinforced Steel Mat/Erosion Control Mat for Slope Reinforcement Project

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords