New Green PVC Coated Wire Mesh Fence with Multi-Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

New Green PVC Coated Wire Mesh Fence with Multi-Purpose

1. Structure of PVC Coated Wire Mesh Fence Description:

Hexagonal wire mesh is also called chicken wire, poultry netting ,rabbit netting. It is common used to fence chicken, poultry, rabbit and other animals.

The hexagonal wire mesh is made of black iron wire, galvanized iron wire, brass wire or stainless steel wire with hexagonal gaps, available in3/8 inch to 4inch ( 10mm to 100mm),wire gauge from BWG14 to BWG27 (2.1mm to 0.4mm).

Hexagonal wire mesh is extensively used in industrial and agricultural construction, building works, and all such made for the purpose of reinforcing and fencing as protective cage, guards for window and machinery safety isolation, floor screen reinforcement and poultry cage, fishing, garden and children's play-ground.

2. Main Features of PVC Coated Wire Mesh Fence :

• Firm structure,

• Flat surface

• Beautiful shape

• Oxidation –resistant

• Nice vision

• Good anti-corrosion

• Anti-oxidation

3. PVC Coated Wire Mesh Fence Images

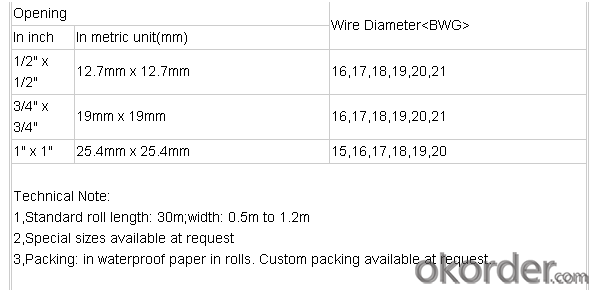

4. PVC Coated wire mesh Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your PVC Coated wire mesh?

Our company is the professional manufacture of PVC Coated wire mesh and any other wire mesh. We have more than 15years experience in producing welded wire mesh. Based on our experience, with our reasonable price, high quality and considerate service, our products enjoy high reputation in our market. Our main products like PVC Coated wire mesh, hot rolled steel plate/coil, cold rolled steel coil, gi steel coil, pp gi coil, corrugated sheet, wire rod and so on. We have established business relationships with clients in the Southeast Asia,South Asia, North America, and many other countries and regions.

② The reason why you choose us

· Diversification of products

. Professional sales team

· Industry experience over 15 years

· Shipment of goods -More than 50 countries worldwide

· We have the most convenient transport and prompt delivery

· We offer competitive price with best service

· We have win high reputation based on best quality products

③ How long can we receive the product after purchase?

In the purchase of PVC Coated wire mesh within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: Can steel wire mesh be used in marine environments?

- Yes, steel wire mesh can be used in marine environments. Steel is known for its high strength and durability, making it suitable for marine applications where the mesh needs to withstand harsh conditions such as saltwater, waves, and corrosion. Additionally, steel wire mesh can provide effective protection against marine creatures or debris, making it commonly used in marine construction, fishing nets, and aquaculture systems. However, to enhance its performance and longevity in marine environments, it is recommended to use stainless steel wire mesh, as it offers superior corrosion resistance compared to other types of steel.

- Q: How is steel wire mesh used in reinforcement of foundations?

- Steel wire mesh is commonly used in the reinforcement of foundations to enhance their strength and durability. It is typically placed within the concrete during the pouring process to provide additional support and prevent cracking or shifting. The steel wire mesh acts as a reinforcing material that helps distribute the load evenly across the foundation structure. It helps to counteract the forces that can cause the concrete to crack or break under excessive weight or pressure. By reinforcing the foundation with steel wire mesh, the overall structural integrity of the foundation is improved, making it more resistant to settling, shifting, and other forms of structural damage. In addition to providing strength, steel wire mesh also helps to control the formation of cracks in the foundation. When concrete cures, it tends to shrink and develop small cracks. However, the presence of steel wire mesh helps to limit the width and length of these cracks, preventing them from spreading and compromising the foundation's stability. Steel wire mesh is also beneficial in reinforcing foundations against external forces, such as earthquakes or soil movement. In regions prone to seismic activity or areas with expansive soils, the addition of steel wire mesh can help absorb and dissipate the energy generated by these forces. This reinforcement reduces the likelihood of foundation failure or significant damage during such events. Overall, the use of steel wire mesh in the reinforcement of foundations provides added strength, durability, and resistance to cracking and shifting. It ensures that the foundation can withstand the various loads and forces it may encounter throughout its lifespan, improving the overall stability and longevity of the structure.

- Q: Can steel wire mesh be used for material handling?

- Yes, steel wire mesh can be used for material handling. Steel wire mesh is a strong and durable material that is commonly used in various industries for handling and transporting materials. It is often used as a base or lining for containers, cages, and pallets to provide support and stability for the materials being transported. Steel wire mesh can also be formed into different shapes and sizes to create custom storage and handling solutions. Additionally, its open design allows for good visibility and ventilation, making it suitable for storing and handling materials that require airflow or visual inspection. Overall, steel wire mesh is a versatile material that can effectively be used for material handling purposes.

- Q: Can steel wire mesh be used for playground equipment?

- Yes, steel wire mesh can be used for playground equipment. Steel wire mesh is a versatile and durable material that can provide numerous benefits for playground equipment. It is commonly used to create barriers, fences, climbing structures, and safety nets in playgrounds. The strength and resilience of steel wire mesh make it suitable for supporting children's weight and ensuring their safety during play. Additionally, steel wire mesh is resistant to corrosion and can withstand various weather conditions, making it a long-lasting choice for playground equipment. The mesh design also allows for good visibility and ventilation, promoting a safe and enjoyable play environment.

- Q: Can steel wire mesh be customized to specific sizes?

- Yes, steel wire mesh can definitely be customized to specific sizes. Steel wire mesh is a versatile material that can be fabricated and cut to various dimensions to meet specific requirements. Whether it is for industrial, commercial, or residential applications, manufacturers can customize the size of steel wire mesh based on the specifications provided by the customer. This customization process involves cutting, welding, and shaping the steel wires to create mesh panels in the desired size and shape. Customization allows for precise fitting and ensures that the steel wire mesh meets the exact needs of the project, whether it is for fencing, filtration, reinforcement, or any other application.

- Q: What are the safety considerations when working with steel wire mesh?

- When working with steel wire mesh, there are several safety considerations that need to be taken into account. 1. Personal Protective Equipment (PPE): It is important to wear the appropriate PPE, such as gloves, safety glasses, and steel-toed boots, to protect oneself from potential hazards. Steel wire mesh can have sharp edges or protruding ends that may cause cuts or punctures, and gloves can help prevent such injuries. 2. Handling and lifting: Steel wire mesh can be heavy and cumbersome to handle, so it is crucial to use proper lifting techniques and equipment when moving or transporting it. Team lifting may be necessary for larger and heavier pieces to avoid strain or injury. 3. Secure installation: When installing steel wire mesh, it is essential to ensure that it is adequately secured to prevent it from shifting or falling. This may involve using appropriate fasteners or supporting structures to maintain stability. Failing to secure the mesh properly can lead to accidents or injuries. 4. Sharp edges and protruding ends: Steel wire mesh may have sharp edges or protruding ends that can cause cuts or punctures. It is important to inspect the mesh for any sharp or jagged edges before working with it. If any such hazards are identified, they should be addressed or removed before proceeding. 5. Welding hazards: In some cases, steel wire mesh may need to be welded or joined together. Welding poses its own set of safety considerations, such as the risk of burns, eye injuries from arc flash, and fumes or gases emitted during the process. Proper ventilation, welding screens, and welding helmets should be used to protect against these hazards. 6. Structural integrity: Steel wire mesh is often used for structural support or reinforcement. It is crucial to ensure that the mesh is in good condition and meets the required specifications for load-bearing capacity. Any signs of damage or weakness should be addressed promptly to maintain the structural integrity and prevent accidents or collapses. 7. Training and awareness: All workers involved in working with steel wire mesh should receive proper training on its safe handling, installation, and maintenance. They should be aware of the potential hazards associated with this material and how to mitigate them. Regular safety briefings and reminders can help reinforce these practices. By following these safety considerations, workers can minimize the risk of accidents or injuries when working with steel wire mesh. It is crucial to prioritize safety at all times to create a secure working environment.

- Q: Can steel wire mesh be used for security doors?

- Yes, steel wire mesh can be used for security doors. Steel wire mesh is a strong and durable material that can effectively provide security for doors. It is commonly used in security doors because it is difficult to cut or break, making it a reliable option for preventing unauthorized access. Additionally, steel wire mesh allows for good visibility and airflow, making it suitable for applications where ventilation and visibility are important. It is also resistant to corrosion, which enhances its longevity and makes it suitable for outdoor use. Overall, steel wire mesh is a popular choice for security doors due to its strength, durability, visibility, and resistance to corrosion.

- Q: How is steel wire mesh used in reinforcement of power plants?

- Steel wire mesh is commonly used in the reinforcement of power plants for various purposes. One of the main uses of steel wire mesh is in the construction of concrete structures. Power plants often have high-stress areas that require reinforced concrete for added strength and durability. Steel wire mesh is embedded within the concrete to provide tensile strength and prevent cracking or structural failure. In power plants, steel wire mesh is also used for the reinforcement of walls and flooring systems. These areas are subject to heavy loads and vibrations, and steel wire mesh helps to distribute the load and enhance the overall structural integrity. By providing additional support, steel wire mesh helps to prevent the formation of cracks and ensures the longevity of the power plant's infrastructure. Additionally, steel wire mesh is used in the reinforcement of cooling towers and chimneys within power plants. Cooling towers are exposed to harsh environmental conditions, including extreme temperatures and moisture. Steel wire mesh helps to reinforce the concrete structures, making them more resistant to corrosion and damage. Furthermore, steel wire mesh is used in the reinforcement of power plant fences and security barriers. These structures are crucial for maintaining the safety and security of the power plant facility. Steel wire mesh is installed to create a strong and impenetrable barrier that prevents unauthorized access and protects the power plant from potential threats. Overall, steel wire mesh is an essential component in the reinforcement of power plants. It enhances the strength and durability of concrete structures, provides support for heavy loads and vibrations, protects against corrosion, and ensures the security of the facility. Its versatility and reliability make steel wire mesh an ideal choice for reinforcing various areas in power plants.

- Q: What are the anti-slip properties of steel wire mesh?

- Steel wire mesh has excellent anti-slip properties due to its textured surface and high coefficient of friction. The interwoven wire strands create a rough and stable surface, providing a secure grip for pedestrians and vehicles, even in wet or slippery conditions.

- Q: How is steel wire mesh used in industrial settings?

- Steel wire mesh is extensively used in various industrial settings for a wide range of applications. One of the primary uses of steel wire mesh is in filtration processes. It is commonly employed as a filter medium to separate particles and contaminants from liquids and gases. The mesh acts as a barrier, allowing the fluid to pass through while trapping unwanted debris, thus ensuring a cleaner and purer end product. Another significant application of steel wire mesh is in reinforcement and construction. It is widely used to reinforce concrete structures, such as roads, bridges, and buildings. The mesh provides additional strength and structural integrity to the concrete, preventing cracks and enhancing its durability. Additionally, it helps distribute the load evenly, reducing the risk of structural failure. Steel wire mesh is also utilized for security purposes in industrial settings. It is commonly used to create fencing and enclosures to restrict access to specific areas, ensuring the safety and protection of personnel and assets. The mesh's strength and rigidity make it an effective barrier against unauthorized entry, vandalism, and theft. In industrial manufacturing processes, steel wire mesh finds applications in material handling, sorting, and sieving operations. It is often employed as conveyor belts or screens to transport or separate materials based on their size, shape, or composition. The mesh can withstand heavy loads, high temperatures, and harsh environments, making it suitable for various industries, including mining, food processing, and recycling. Furthermore, steel wire mesh is used in industrial settings for ventilation and heat dissipation. It is commonly utilized as ventilation panels or screens to allow the free flow of air while preventing the entry of unwanted objects. This helps maintain optimal air quality, temperature, and humidity levels within industrial spaces, promoting a healthier and more comfortable working environment. Overall, steel wire mesh plays a crucial role in industrial settings due to its versatility, strength, and durability. Its applications range from filtration and reinforcement to security, material handling, and ventilation. As a result, it is an indispensable component in numerous industries, contributing to improved efficiency, safety, and productivity.

Send your message to us

New Green PVC Coated Wire Mesh Fence with Multi-Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords