Construction Reinforcing Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 170 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

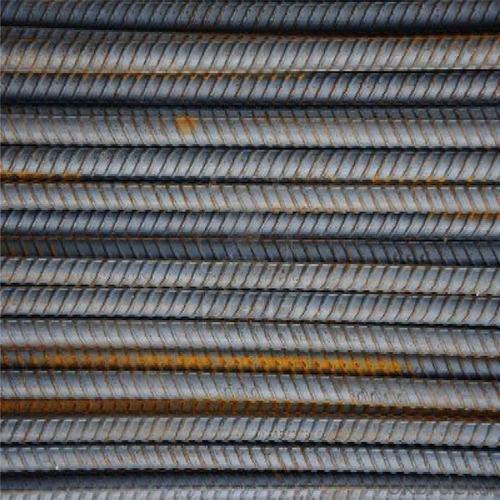

Construction Reinforcing Steel

Description of Construction Reinforcing Steel

1, Diameter: 5.5mm-10mm Construction Reinforcing Steel

10m- 40mm Construction Reinforcing Steel

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

Chemical Composition of Construction Reinforcing Steel

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of Construction Reinforcing Steel

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel contribute to the aerospace aftermarket industry?

- The aerospace aftermarket industry heavily relies on special steel to provide critical components that are vital for the safe and efficient operation of aircraft. Special steel possesses high strength, durability, and temperature resistance, making it an ideal material for a wide range of aerospace applications. Engine components are primarily manufactured using special steel, particularly nickel-based superalloys. These alloys are used to produce turbine blades, compressor discs, and shafts, which are essential elements of jet engines. These components must be able to withstand extreme temperatures, pressures, and mechanical stresses, and special steel alloys offer the necessary properties to ensure reliable and long-lasting performance. Special steel is also utilized in the production of structural components in aircraft. Steel alloys with high strength-to-weight ratios, such as titanium alloys, are employed to construct critical parts like landing gear, wing spars, and fuselage frames. These components need to be lightweight yet strong enough to endure the forces and stresses experienced during flight. Special steel alloys provide the required mechanical properties to ensure the structural integrity and safety of the aircraft. In addition to engine and structural components, special steel is crucial for the production of fasteners, bearings, and other small but vital parts. These components play a significant role in holding various parts together and ensuring the proper functioning of systems. Special steel alloys with exceptional corrosion resistance, fatigue strength, and wear resistance are used to guarantee the reliability and longevity of these critical components. Furthermore, special steel plays a vital role in the maintenance, repair, and overhaul (MRO) activities of the aerospace aftermarket industry. Due to the rigorous demands placed on aircraft components, regular inspections, repairs, and replacements are necessary to maintain their airworthiness. Special steel materials are commonly used for MRO purposes because they are compatible with existing aircraft systems and can meet the stringent requirements of aerospace regulations. Overall, special steel is an indispensable material in the aerospace aftermarket industry. Its unique properties and characteristics enable the production of high-performance engine components, lightweight structural parts, and reliable small components. The use of special steel ensures the safety, efficiency, and longevity of aircraft, contributing to the overall success and growth of the aerospace aftermarket industry.

- Q: How is heat-resistant steel used in the production of furnaces and boilers?

- Heat-resistant steel is used in the production of furnaces and boilers due to its ability to withstand high temperatures. It is utilized in various components such as heat exchangers, tubes, and piping systems, ensuring efficient heat transfer and preventing structural damage. This steel's resistance to oxidation and corrosion guarantees longevity and reliability, making it an essential material for manufacturing furnaces and boilers.

- Q: How does stainless steel contribute to the production of medical implants?

- Stainless steel contributes to the production of medical implants by providing a highly durable and corrosion-resistant material that is compatible with the human body. It is used in various implants such as joint replacements, dental implants, and surgical instruments due to its strength, biocompatibility, and ability to withstand sterilization processes.

- Q: What is the importance of heat treatment in special steel?

- Heat treatment is of utmost importance in special steel because it significantly enhances its mechanical properties and overall performance. Special steel, also known as alloy steel, is specifically designed to possess specific characteristics such as high strength, hardness, wear resistance, and toughness, making it suitable for demanding applications in industries like automotive, aerospace, and tooling. The heat treatment process involves controlled heating and cooling of the steel to alter its microstructure, which in turn affects its properties. There are several heat treatment techniques employed, including annealing, tempering, quenching, and hardening, each serving a specific purpose. One key importance of heat treatment in special steel is the ability to increase its hardness. Through techniques like quenching and hardening, the steel can be transformed into a hardened state, where it becomes much stronger and more resistant to abrasion and wear. This is crucial for applications that involve heavy loads, impact, and abrasive environments. Additionally, heat treatment can also improve the toughness and ductility of special steel. By carefully controlling the cooling rate during the heat treatment process, the steel's microstructure can be adjusted to achieve a fine-grained structure, enhancing its toughness and ability to withstand sudden impacts or shocks. This is particularly important in applications where the material needs to absorb energy and resist fractures, such as in structural components or tools. Furthermore, heat treatment can also improve the machinability and dimensional stability of special steel. By subjecting the steel to annealing or tempering processes, internal stresses and residual strains can be relieved, resulting in a more stable and easier-to-machine material. This is crucial in industries where precision and dimensional accuracy are paramount. In conclusion, the importance of heat treatment in special steel cannot be overstated. It is a vital process that allows for the optimization of the steel's mechanical properties, ensuring it meets the specific requirements of demanding applications. By carefully manipulating the microstructure, heat treatment enhances the steel's hardness, toughness, and machinability, making it a versatile and reliable material in various industries.

- Q: How does electrical steel minimize energy losses in electrical devices?

- Electrical steel minimizes energy losses in electrical devices through its unique magnetic properties and composition. It is specifically designed to have low electrical conductivity and high magnetic permeability, which reduces eddy current losses and hysteresis losses. These losses occur due to the alternating magnetic fields generated in electrical devices, such as transformers and motors. By using electrical steel, these losses are minimized, resulting in more efficient energy transfer and reduced energy wastage.

- Q: What are the main applications of special steel in the food processing machinery?

- Special steel is commonly used in food processing machinery due to its unique properties and benefits. The main applications of special steel in food processing machinery include ensuring hygiene and cleanliness, resistance to corrosion and wear, high strength and durability, and compatibility with food safety regulations.

- Q: What are the different forging techniques for special steel parts?

- There are several different forging techniques that can be used to produce special steel parts, depending on the desired shape, size, and properties of the final product. Some of the commonly used forging techniques for special steel parts include: 1. Open-die forging: This technique involves shaping the metal between flat dies or anvils. It is typically used for simpler shapes and allows for flexibility in producing a wide range of sizes. 2. Closed-die forging: Also known as impression-die forging, this technique involves shaping the metal within a closed die, which contains the desired shape and allows for higher precision. Closed-die forging is commonly used for producing complex and intricate shapes. 3. Upset forging: In this technique, the metal is compressed and shaped by applying pressure to the ends of the workpiece. Upset forging is often used to create parts with increased diameter or reduced length, such as bolts and nails. 4. Ring rolling: This technique involves shaping a cylindrical workpiece by applying pressure from rotating rolls. It is commonly used for producing seamless rings with enhanced strength and durability, such as gears, bearings, and flanges. 5. Isothermal forging: This technique involves forging the metal at a constant temperature, usually within a specially designed furnace. Isothermal forging allows for precise control over the metallurgical properties of the final product, resulting in improved mechanical properties and reduced residual stress. 6. Precision forging: Also known as near-net-shape forging, precision forging uses specially designed dies to produce parts with minimal finishing operations. It is commonly used for complex shapes and high-volume production, ensuring cost-effectiveness and dimensional accuracy. 7. Press forging: In this technique, the metal is shaped by applying pressure through a mechanical or hydraulic press. Press forging allows for precise control over the forging process and is often used for producing high-strength, large-sized components. Each of these forging techniques offers unique advantages and is suitable for different applications. The selection of the appropriate forging technique for special steel parts depends on factors such as the desired shape, size, strength, and cost-effectiveness of the final product.

- Q: What are the specific requirements for special steel used in nuclear applications?

- To ensure the suitability and safety of special steel used in nuclear applications within the demanding nuclear environment, specific requirements must be met. These requirements are designed to maintain the integrity and performance of the steel under various conditions, including extreme temperatures, radiation exposure, and corrosive environments. One primary requirement for special steel in nuclear applications is its need for high strength and toughness. The steel must possess exceptional mechanical properties to withstand the immense pressure and stress it will encounter during operation. This enables the steel to resist deformation, cracking, and failure, ensuring the structural integrity of nuclear components. Another critical requirement is the ability to withstand high temperatures and thermal cycling. Nuclear reactors operate at elevated temperatures, and the steel must retain its mechanical properties even under extreme thermal conditions. This prevents any degradation or loss of strength that could compromise the safety and efficiency of the nuclear system. Furthermore, special steel used in nuclear applications must exhibit exceptional resistance to corrosion and oxidation. The nuclear environment can be highly corrosive due to the presence of various chemicals and coolants, such as water, steam, and coolant gases. The steel must possess a high level of corrosion resistance to prevent any degradation or material loss, which could lead to leaks or failures. Radiation resistance is also a critical requirement for special steel used in nuclear applications. Nuclear reactors emit ionizing radiation, which can damage the structure and properties of conventional materials. Therefore, the steel must have a high resistance to radiation-induced embrittlement and degradation, ensuring its long-term performance in a radioactive environment. Additionally, the steel used in nuclear applications must comply with strict quality control and certification standards. These standards ensure the traceability, material composition, and manufacturing processes of the steel, guaranteeing its reliability and compliance with regulatory requirements. Quality control measures include non-destructive testing, ultrasonic examinations, and material certification. Overall, the specific requirements for special steel used in nuclear applications encompass high strength, toughness, thermal stability, corrosion resistance, radiation resistance, and adherence to stringent quality control standards. Meeting these requirements is crucial to ensure the safe and reliable operation of nuclear systems while mitigating potential risks associated with the nuclear environment.

- Q: How does the heat treatment process affect the properties of special steel?

- The heat treatment process has a significant impact on the properties of special steel. This process involves heating and cooling the steel in a controlled manner to alter its microstructure and, consequently, its mechanical properties. Firstly, heat treatment can enhance the hardness of special steel. By heating the steel to a specific temperature, followed by rapid cooling, a process known as quenching, the steel undergoes a phase transformation that increases its hardness. This is particularly beneficial for applications that require high strength and wear resistance, such as cutting tools or bearings. Additionally, heat treatment can improve the toughness of special steel. By tempering the quenched steel at a lower temperature, the brittleness caused by the rapid cooling can be reduced, leading to improved toughness and impact resistance. This is crucial for applications where the steel needs to withstand sudden shocks or impacts, such as in automotive or aerospace components. Moreover, heat treatment can also enhance the overall strength of special steel. Through a combination of heating, cooling, and tempering processes, the steel's grain structure can be refined, resulting in improved strength and resistance to deformation. This is particularly important for structural applications, where the steel needs to withstand heavy loads or extreme conditions. Furthermore, the heat treatment process can also influence the corrosion resistance of special steel. By subjecting the steel to specific heat treatment cycles, the formation of certain phases or chemical compounds can be promoted, leading to improved resistance against corrosion or oxidation. This is essential for applications exposed to harsh environments or corrosive substances, such as in marine or chemical industries. In conclusion, the heat treatment process plays a vital role in altering the properties of special steel. By carefully controlling the heating, cooling, and tempering cycles, the hardness, toughness, strength, and corrosion resistance of the steel can be significantly enhanced. This allows for the production of special steel with tailored properties to meet the specific requirements of various industrial applications.

- Q: What are the different production methods for special steel?

- There are several different production methods for special steel, each with its own unique advantages and characteristics. Some of the most common methods include: 1. Electric Arc Furnace (EAF): This method involves melting scrap steel in an electric arc furnace, where an electric current generates intense heat to melt the materials. EAF is popular for its flexibility, as it can produce a wide range of steel grades and alloys. 2. Basic Oxygen Furnace (BOF): In this process, molten iron from a blast furnace is combined with scrap steel and oxygen to remove impurities and adjust the carbon content. BOF is known for its high production capacity and ability to produce large quantities of steel. 3. Vacuum Induction Melting (VIM): VIM is a method used to produce high-quality and high-purity steel. It involves melting the raw materials in a vacuum environment to prevent contamination and achieve precise control over the alloy composition. 4. Continuous Casting: This method involves pouring molten steel into a water-cooled mold, which continuously produces solidified steel slabs, blooms, or billets. Continuous casting is known for its efficiency and ability to produce consistent and defect-free steel products. 5. Powder Metallurgy: This technique involves compacting and sintering metal powders to produce steel with specific properties. Powder metallurgy allows for the production of complex shapes, improved mechanical properties, and the incorporation of alloying elements that are challenging to achieve through traditional methods. 6. Additive Manufacturing (AM): Also known as 3D printing, AM is a relatively new method for producing special steel. It involves layer-by-layer deposition of metal powders, which are then fused together using heat or a laser. AM offers great design freedom, the ability to produce complex geometries, and the potential for customized steel parts. Each production method has its own advantages and limitations, and the choice depends on factors such as the desired steel properties, production volume, cost considerations, and the specific requirements of the end-use application.

Send your message to us

Construction Reinforcing Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 170 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords