Hex Galvanized Wire Netting for Chicken and Farm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

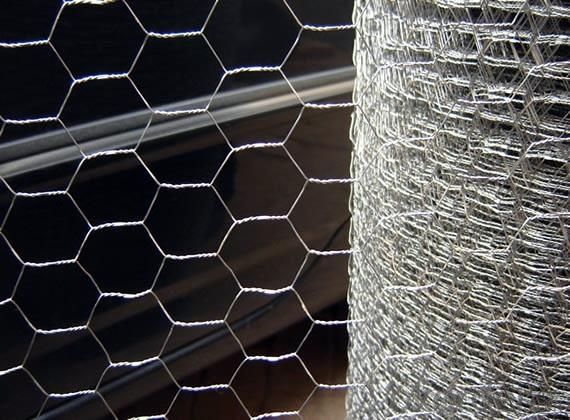

Introduction of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Galvanized Hexagonal Wire Mesh

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Can steel wire mesh be used for screen printing?

- Indeed, screen printing can utilize steel wire mesh effectively. The prevalence of steel wire mesh as a screen printing medium stems from its robustness and potency. It furnishes a firm and steady platform for the ink to permeate, guaranteeing precise and uniform prints. Diverse mesh counts are accessible, permitting varying degrees of intricacy in the print. Moreover, steel wire mesh exhibits resistance to deterioration, rendering it an enduring choice for screen printing endeavors.

- Q: Is steel wire mesh resistant to alkalis or acids?

- Yes, steel wire mesh is generally resistant to alkalis and acids due to its corrosion-resistant properties.

- Q: Is steel wire mesh resistant to vibration?

- Yes, steel wire mesh is generally resistant to vibration. The high tensile strength of steel and the interlocking nature of the wire mesh make it capable of withstanding vibrations and mechanical stress. The rigid structure of steel wire mesh helps to prevent deformation or damage caused by vibrations, making it a reliable choice for applications where vibration resistance is required. Additionally, the durability and longevity of steel wire further enhance its ability to resist vibrations over an extended period.

- Q: How does steel wire mesh perform in high-impact applications?

- Due to its inherent strength and durability, steel wire mesh is highly effective in high-impact applications. The solid and rigid framework created by the interlocking nature of the mesh structure enables it to withstand significant force and impact. By evenly distributing the force across its surface area, the steel wire mesh prevents localized stress concentrations and potential damage. This capability allows the mesh to absorb and dissipate the energy generated during impact, thus minimizing the risk of deformation, breakage, or failure. Furthermore, steel wire mesh possesses excellent ductility, meaning it can deform under extreme loads while maintaining its structural integrity. This ability to effectively absorb and distribute impact energy makes steel wire mesh a perfect material for fencing, protective barriers, reinforcing concrete structures, and guarding industrial machinery.

- Q: How is steel wire mesh used in reinforcement of water projects?

- Due to its strength and durability, steel wire mesh is a commonly utilized material in the reinforcement of water projects. Its primary function is to strengthen concrete structures like dams, reservoirs, water tanks, and pipelines. When constructing water projects, it is customary to incorporate steel wire mesh into the concrete to provide added strength and support. This helps prevent cracking and improves the overall structural integrity of the project. By acting as a reinforcement grid, the mesh evenly distributes the load throughout the concrete. Strategic placement of the steel wire mesh is typically done in areas where high tensile strength is necessary, such as locations prone to water pressure or exposed to environmental factors that could cause damage. Additionally, the mesh is used to reinforce joints and corners, which are more susceptible to cracking and require extra support. Another advantage of using steel wire mesh in water projects is its resistance to corrosion. As water projects are often exposed to moisture, chemicals, and other corrosive elements, the use of corrosion-resistant materials like stainless steel ensures the longevity and performance of the mesh in these harsh environments. In summary, steel wire mesh plays a crucial role in enhancing the strength, durability, and resistance to cracking of water projects. It safeguards the long-term integrity of structures, protecting them from potential damage caused by water pressure, environmental factors, and corrosion.

- Q: Can steel wire mesh be used for soundproofing?

- No, steel wire mesh alone is not effective for soundproofing as it does not provide sufficient sound insulation.

- Q: How does steel wire mesh perform in high-pressure environments?

- Steel wire mesh is known for its exceptional strength and durability, making it highly suitable for high-pressure environments. When subjected to high pressure, steel wire mesh demonstrates excellent resistance against deformation and stretching, ensuring its structural integrity remains intact. This resilience is due to the inherent strength and rigidity of steel, which allows the wire mesh to withstand immense pressure without compromising its shape or performance. Additionally, steel wire mesh is highly resistant to corrosion, which further enhances its suitability for high-pressure environments. The steel material used in the wire mesh is often treated or coated to prevent rusting and corrosion, ensuring that it can withstand the harsh conditions associated with high-pressure environments, such as exposure to moisture, chemicals, or extreme temperatures. The interlocking nature of the wire mesh also contributes to its performance in high-pressure environments. The mesh pattern provides stability and prevents any potential weak points, distributing the pressure evenly throughout the entire surface. This distribution of pressure ensures that the wire mesh can withstand high-pressure conditions without experiencing localized stress concentrations that could lead to failure. Moreover, steel wire mesh offers excellent permeability, allowing for the flow of fluids, gases, or substances through its openings. In high-pressure environments, this permeability can be advantageous as it enables efficient filtration, separation, or containment of materials, while still maintaining the required pressure levels. In conclusion, steel wire mesh is a reliable and robust material for high-pressure environments. Its strength, corrosion resistance, interlocking structure, and permeability make it a suitable choice for applications where pressure resistance is crucial, such as in industrial processes, filtration systems, or high-pressure containment areas.

- Q: Can steel wire mesh be used for gabion fire pits?

- Certainly, gabion fire pits can utilize steel wire mesh. These outdoor fire features are built by employing wire mesh cages that are filled with stones or rocks. Typically, the steel wire mesh utilized for gabions is crafted from galvanized or coated steel, which grants it resistance against both heat and corrosion. This material possesses strength and durability, enabling it to endure the elevated temperatures produced by the fire. The wire mesh serves to confine and stabilize the stones or rocks, thereby establishing a secure and operational fire pit. Nevertheless, it is imperative to verify that the wire mesh employed is specifically designed for fire pits and capable of withstanding the heat generated by the fire.

- Q: How does steel wire mesh perform in terms of resistance to weathering?

- Steel wire mesh is renowned for its remarkable ability to resist weathering. It is composed of robust and corrosion-resistant steel, enabling it to endure diverse weather conditions including rain, snow, heat, and UV exposure. Unlike other materials, steel wire mesh remains unaffected by warping, cracking, or degradation when exposed to these elements. To enhance its resistance to weather, the galvanization process is employed. This involves applying a protective layer of zinc to the steel wire mesh, serving as a moisture barrier and preventing rust formation. Consequently, this additional layer fortifies the mesh, augmenting its durability and extending its lifespan. Moreover, steel wire mesh exhibits exceptional performance in terms of withstanding extreme temperatures. It does not become brittle in cold climates nor compromise its structural integrity in high temperatures. Consequently, it proves suitable for a myriad of applications, including outdoor fencing, construction endeavors, and agricultural uses. Additionally, steel wire mesh showcases impressive resistance to wind and impact. Its inherent strength and flexibility allow it to endure strong gusts without bending or breaking. Hence, it serves as an optimal choice for applications where wind loads are a concern, such as coastal areas or high-rise buildings. All in all, steel wire mesh emerges as an outstanding choice for outdoor applications due to its exceptional resistance to weathering. Its capacity to withstand various weather conditions, coupled with its galvanized coating, resistance to extreme temperatures, and wind resistance, render it a dependable and long-lasting option for a diverse array of projects.

Send your message to us

Hex Galvanized Wire Netting for Chicken and Farm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords