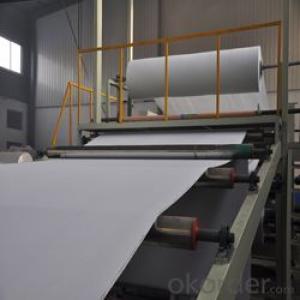

PVC waterproof membrane Reinforced

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC (polyvinyl chloride) roof membrane

is an excellent high quality polymer waterproof sheet, made of PVC resin by adding plasticizer,

anti-UV agent, anti aging agent, and stabilizer and other processing aids through extrusion

and molding.As the highly recommended product by the Ministry of Construction, it is featured by high tensile

strength, great elongation, good stability, small shrinkage, low temperature performances, good resistance to

weathering and root penetration, and long service life.

Physical Property:

1.Good combination of high elasticity and tensile strength.

2.Fine resistance to static electricity.

3.Excellent resistance to ageing / weathering.

4.Durable,the effective age can be more than 20 years used on exposed surfaces,used on non-exposed surfaces,it can reach 50 years.

5.Fine flexibility at low temperature,adaptable to cold conditions.

6.Root-resistance,can be used on the planting roofs.

7.Fine puncture resistance, joint peel strength and joint shear strength.

8.Fine UV-resistance,no pollution to environment.

9.Easily welding,installing,secure.

10.Easy treatments to the delicate parts of corners and edges.

11.Convenient maintenance with low cost.

Polyvinyl Chloride (PVC) membrane with fiber reinforced layer

on the back is widely used in the roofs of civil buildings,

tunnels, channels, subways, highways, planting roofs, the roofs of steel

frame structure buildings, and etc.

- Q: Can a waterproofing membrane be used on terracotta surfaces?

- Terracotta surfaces can benefit from the use of a waterproofing membrane. Due to its porous nature, terracotta absorbs water and can suffer damage and deterioration as a result. To prevent such issues, applying a waterproofing membrane creates a barrier that stops water from penetrating and safeguards the material against moisture-related problems. Acting as a protective layer, the membrane keeps the terracotta surface dry and prevents water from seeping through. This is especially advantageous in areas with high moisture levels or where terracotta is exposed to water, like bathrooms, kitchens, or outdoor installations. To ensure compatibility and effectiveness, it is crucial to select a waterproofing membrane specifically designed for terracotta surfaces. Additionally, following proper surface preparation and application techniques is essential for achieving optimal results.

- Q: Can a waterproofing membrane be used for concrete tank linings?

- Yes, a waterproofing membrane can be used for concrete tank linings. Waterproofing membranes are commonly used in construction to prevent water penetration and provide a protective barrier. When applied to the interior surfaces of a concrete tank, a waterproofing membrane can effectively prevent water from seeping into the tank and causing damage. This is particularly important for tanks that store liquids or chemicals, as any leakage can lead to contamination or structural deterioration. By using a waterproofing membrane, the tank can be safeguarded against water ingress, ensuring its longevity and maintaining its structural integrity.

- Q: Can a waterproofing membrane be used on concrete block surfaces?

- Yes, a waterproofing membrane can be used on concrete block surfaces. Waterproofing membranes are designed to provide a barrier against moisture and water penetration, and they are commonly used on concrete block surfaces to protect against water damage and leaks. These membranes are typically applied as a liquid or sheet material and adhere to the surface of the concrete blocks, creating a protective layer that prevents water from seeping through. The waterproofing membrane helps to extend the lifespan of the concrete blocks by reducing the risk of water damage, mold growth, and deterioration. It is important to choose a waterproofing membrane that is specifically designed for concrete block surfaces and follow the manufacturer's instructions for proper installation to ensure the best results.

- Q: Can a waterproofing membrane be used for foundation repair?

- Foundation repair can be achieved by using a waterproofing membrane. These membranes are widely utilized in order to prevent water infiltration and moisture damage in basements and foundations. The primary purpose of these membranes is to create a barrier against water and other forms of moisture, thereby safeguarding the foundation from further harm and potential structural issues. Applying a waterproofing membrane to the foundation can aid in the repair process by sealing existing cracks or leaks and preventing water from seeping into the foundation, which could lead to additional problems. Furthermore, the utilization of a waterproofing membrane can also reduce the risk of mold and mildew growth, as it decreases the moisture content in the foundation. Ultimately, the use of a waterproofing membrane is an effective technique for foundation repair as it ensures the long-term stability and durability of the foundation.

- Q: Can a waterproofing membrane be used on masonry surfaces?

- Yes, a waterproofing membrane can be used on masonry surfaces. It is a common practice to apply waterproofing membranes on masonry surfaces to prevent water penetration and protect the structure from moisture damage.

- Q: Are waterproofing membranes suitable for stadium structures?

- Yes, waterproofing membranes are suitable for stadium structures. These membranes provide an effective barrier against water infiltration, protecting the structure from potential damage caused by moisture. Additionally, waterproofing membranes are flexible and can accommodate movement in the stadium's structure without compromising their effectiveness.

- Q: Can waterproofing membranes be used on concrete planters?

- Yes, waterproofing membranes can be used on concrete planters. Waterproofing membranes are designed to create a barrier against water, preventing it from seeping through the concrete and causing damage. By applying a waterproofing membrane to the concrete planter, you can ensure that the planter remains watertight, preventing water from leaking out and potentially damaging the surrounding area. This can be especially beneficial for planters located indoors or in areas where water leakage could cause structural damage or create a mess. Additionally, waterproofing membranes can also help protect the concrete from freeze-thaw cycles, which can cause cracking and deterioration over time. Overall, by using waterproofing membranes on concrete planters, you can extend their lifespan and maintain their functionality for a longer period of time.

- Q: Can a waterproofing membrane be used for bridges and overpasses?

- Yes, a waterproofing membrane can be used for bridges and overpasses. Waterproofing membranes are commonly used in the construction industry to protect structures from water infiltration, including bridges and overpasses. These membranes are designed to create a barrier between the structure and moisture, preventing water from seeping into the concrete or steel components. By installing a waterproofing membrane, the lifespan of a bridge or overpass can be significantly extended, as it helps to prevent corrosion, concrete degradation, and other damages caused by water exposure. Additionally, waterproofing membranes can also provide protection against other environmental factors such as freeze-thaw cycles, chemicals, and UV radiation. Therefore, using a waterproofing membrane for bridges and overpasses is a common practice to enhance their durability and longevity.

- Q: Are there any specific considerations for installing a waterproofing membrane on precast concrete surfaces?

- Installing a waterproofing membrane on precast concrete surfaces requires specific considerations. Here are some important points to remember: 1. Proper Surface Preparation: Before applying the waterproofing membrane, it is crucial to prepare the precast concrete surface correctly. This involves cleaning the surface, removing loose particles, and ensuring it is dry and free from any contaminants. 2. Compatibility: It is important to select a waterproofing membrane that is suitable for precast concrete surfaces. Some membranes may not adhere well or provide effective waterproofing on this type of substrate. Therefore, it is essential to choose a membrane specifically designed for use on precast concrete. 3. Ensuring Adhesion: Properly adhering the waterproofing membrane to the precast concrete surface is vital. It is important to carefully follow the manufacturer's instructions, including any surface priming or preparation requirements for optimal adhesion. Proper adhesion will prevent water infiltration and concrete damage. 4. Joint Treatment: Precast concrete surfaces often have joints between panels or components. These joints need proper treatment to maintain the system's waterproofing integrity. This may involve using joint sealants or tapes designed specifically for waterproofing purposes. 5. Considering Durability: Consider the durability and longevity of the waterproofing membrane. Precast concrete surfaces are exposed to various weather conditions and environmental factors. Therefore, it is crucial to choose a membrane that can withstand these conditions and provide long-term protection against water penetration. 6. Quality Assurance: It is recommended to work with experienced professionals or certified installers to ensure the proper installation of the waterproofing membrane on precast concrete surfaces. This minimizes the risk of installation errors and ensures that the waterproofing system performs as intended. By considering these factors, installing a waterproofing membrane on precast concrete surfaces can effectively protect the concrete from water damage and extend its lifespan.

- Q: Are waterproofing membranes resistant to root penetration?

- Yes, waterproofing membranes are generally resistant to root penetration. These membranes are specifically designed to prevent water from penetrating through the surface and into the underlying structure. In addition to their water resistance, they also possess qualities that make them resistant to root penetration. This is important in areas where vegetation or trees may be present, as roots have the potential to grow and penetrate through various surfaces, causing damage and compromising the integrity of the waterproofing system. Waterproofing membranes are typically made from materials that are tough and durable, providing a barrier that roots cannot easily penetrate. However, it is important to note that no waterproofing membrane is completely immune to root penetration, as some root systems may be particularly aggressive or invasive. In these cases, additional measures such as root barriers or specialized membranes may be necessary to ensure long-term protection against root penetration.

Send your message to us

PVC waterproof membrane Reinforced

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords