Laminate Flooring Brands

Laminate Flooring Brands Related Searches

Laminate Flooring For Sale Laminate Flooring Cost Laminate Flooring Ratings Garage Laminate Flooring Laminate Flooring Tape Low Pressure Laminate Manufacturers Acclimate Laminate Flooring Laminate Flooring Instalation Nirvana Laminate Flooring Luxury Flooring Kronotex Laminate Flooring Under Laminate Flooring Formica Laminate Flooring 12 Laminate Flooring High Pressure Laminate Manufacturers Europe Lube Oil Brands Trim Laminate Flooring Melamine Laminate Sheets Suppliers Kitchen Laminate Countertops Exterior Grade Laminates Lvt Flooring Automotive Rubber Flooring Formica Laminate Finishes Floating Flooring High Pressure Laminate Supplier Philippines Outdoor Hpl Laminate Formica Laminate Samples Shaw Laminate Glossy Laminate Countertops Warm Flooring For BathroomsLaminate Flooring Brands Supplier & Manufacturer from China

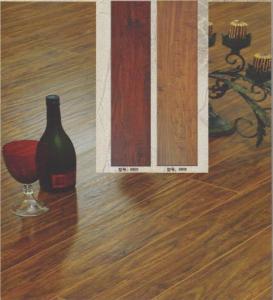

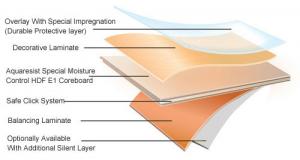

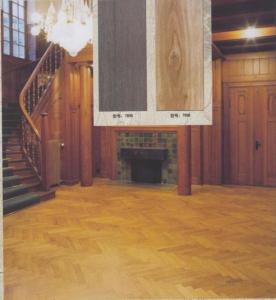

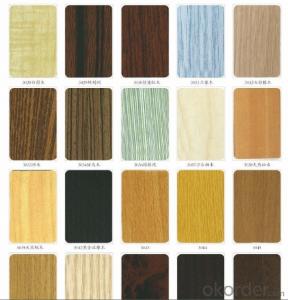

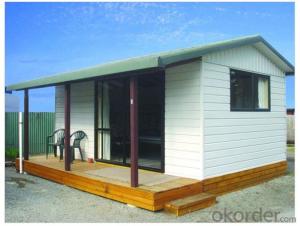

Laminate Flooring Brands offer a wide range of high-quality flooring options that cater to various design preferences and functional needs. These products are designed to provide a durable and aesthetically pleasing solution for both residential and commercial spaces. Laminate flooring is known for its ability to mimic the appearance of natural materials such as wood and stone, while offering the benefits of being easy to install, maintain, and resistant to wear and tear. This makes it a popular choice for homeowners and businesses alike, as it combines the beauty of traditional flooring materials with the practicality of modern construction techniques.Laminate flooring is widely used in various application scenarios, including living rooms, bedrooms, kitchens, and offices. Its versatility allows it to be installed in spaces with high foot traffic, making it an ideal choice for busy households and commercial establishments. The product is also praised for its ability to withstand moisture and resist scratches, which makes it suitable for areas prone to spills and accidents. Furthermore, laminate flooring is known for its ease of installation, requiring minimal tools and expertise, which can save time and labor costs during the installation process.

Okorder.com is a reputable wholesale supplier of Laminate Flooring Brands, boasting a large inventory that caters to the diverse needs of customers. The company is committed to providing top-quality products at competitive prices, ensuring that clients receive the best value for their investment. With a strong focus on customer satisfaction, Okorder.com offers a seamless shopping experience, backed by excellent customer service and support. This makes it a preferred choice for those looking to purchase laminate flooring for their projects, as they can rely on the company's expertise and commitment to delivering exceptional products.

Hot Products