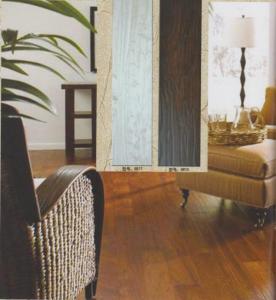

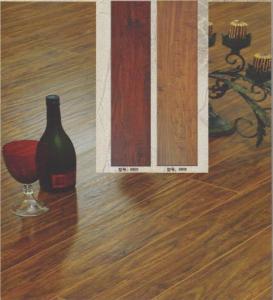

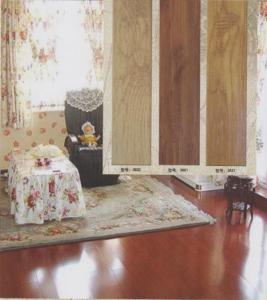

Embossed Surface Laminated Flooring with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Embossed Surface Laminated Flooring

Quick Details

Type: Engineered Flooring

Technics: Laminate Flooring

Core Material: MHDF,HDF

Density: from 800kgs/m3-900kgs/m3

Grade: AC1-AC5

Clicks: single clicks, double clicks, arc clicks

Surface Finish:embossed/crystal/silk/mirror/handscraped/synchronized surface

Color: thousands of wooden colors for you to choose

packing: with paper Carton

OEM: OEM with your logo and design on paper carton

accessories: available with same color as flooring ordered

Specifications

Laminated Flooring

1.single /double/Valinge click

2.white/brown core HDF

3.AC1-AC5

4.surface:embossed/silk

Our Advantage

1.Free samples in each container

2.Free new design products in each container

3.Make samples according to partner’s request

4.Make selling plan in your market together

5.Visit your company when there is a chance

Packaging & Delivery

1)The flooring are put in paper carton, the carton is wrapped with plastic bag for protection. |

within 15-30days after receiving deposit or L/C |

Picture

- Q: Living room is a good solid wood flooring or solid wood composite

- Advantages: 1 durable: from the whole wood processing, solid wood floor thickness of 18mm, to ensure wear resistance.2 environmental protection: it comes from natural wood, formaldehyde free, no harm to the human body.3 foot: good elasticity, temperature, touch, feel soft and comfortable.4 cool in summer and warm in winter: wood thermal conductivity is small, there is a good role in temperature regulation.

- Q: Can I use Liquid nails (subfloor or HD) to glue down 3/8 thick engineered hardwood flooring? If so what are the disadvantages vs urethane flooring glue? And if not, why? The manufacturer's directions say the floor can be installed over wood sub flooring via nailed, glued or floating (with glued joints). Urethane flooring glue runs $40 per gallon/(40sq ft) at both Lowes and Home depot. Liquid nails would be much cheaper and simple to use. The room is small at only 130sq ft. thanks

- I would use what the manufacturer suggest and it probably isn't liquid nails. Although, it could work, it's not worth having the enrtire floor ruined by this. If the cost of glue is the issue, maybe consider floating it. If you decide to buyt the glue I like Bostiks Best.

- Q: What is the difference between laminate flooring and ten solid wood flooring

- The three layer structure of wood flooring, formed by three layers of laminated wood staggered surface quality specifications, hardwood lath Xiangpin, commonly used species for Manchurian ash, birch, beech, oak, maple, cherry, etc.. The middle of the soft wood strip, the bottom of the veneer veneer, arranged in a crisscross. The structure of the utility model can make the three layer solid wood composite floor not only have the advantages of the ordinary solid wood floor, but also effectively adjust the internal stress between the wood, and improve the defects of the wood with the change of the seasonal dry humidity.

- Q: My home is a solid wood floor, in the time of moving the furniture accidentally knocked off the floor layer of skin, it is difficult to see how to repair?

- Part of the repair of the destruction of the first need to replace the solid wood floor destroyed, and then completely removed. In practice, using the tool to replace the solid wood floor at the short side cut out a gap, then saw the need to replace the sawn wood floor surface, and then will be divided into small pieces of wood floor removed, but this process to ensure that does not damage the surrounding wood floor. After the removal of the solid wood floor, but also to clean up around the glue, to ensure that the cleaning of the tenon and groove easy to install. If the cleaning is not complete, the seam will be uneven or lax. In the processing of glue, can use a new sliding tenon piece of wood floors in the interface on the back and forth, find out and remove the residual glue, to ensure the restoration of the appearance of solid wood flooring.

- Q: How do I remove a glued down engineered wood floor on a slab foundation?

- Do you have to remove it? Can't you just put the new floor on top of it? The glue is probably water proof right? If the glue is water proof, then you might have to chisel the floor out. I think you can get a special bit for an electric jack hammer that - if you are really carefull - will rip up the wood without damaging the slab too terribly. You might have to resurface the concrete - not expensive if you DIY - if you do too much damage.

- Q: I am considering engineered flooring of good quality, since you can get better value for exotic wood. the sample i am considering is natural dark wood, which is expensive with solid hardwood. the Aluminum oxide coating with prefinished flooring cannot be applied on site, and makes the wood more resistent.

- I think they are equal in adding value. The engineered wood is more practical because it does not warp like all solid wood.

- Q: The floor, the floor to the factory maintenance time, the new floor miaojie special oil, was trying to sell me, too expensive, not to buy. Want to go to the supermarket to buy a little, but do not know what brand is good, to understand the MM point of view ah, thank you!

- Every time a time interval as the floor wax, paint finish and suggestions, at least annually cerated maintain two. The first method is to use semi dry cloth to clean the floor and waxing, floor to wax evenly on the floor surface and make the "soak", such as a soft cloth slightly dry with a dry wipe back and forth on the floor, until smooth and bright so far.

- Q: I would like to ask the solid wood floor can bask in the sun? My home is very abundant sunshine, the basic drying day

- Often appear from the seam, the film will bubble, discoloration, or even out of.

- Q: I want to decorate the house, I would like to ask how to buy real wood floor?

- Color: quality wood floors should be natural color, clear wood. If the color of the floor surface is heavy, the paint layer is thicker, it may be for the purpose of covering the surface defects of the floor, and when the floor for the six side of the paint when the need to pay attention to. At the same time, due to the different plate in its parent trees -- where there are differences in sapwood and heartwood, wood table, wood, nightside, sun, respectively, tangential diameter cut and sheet metal cutting, so there must be color. It is the color, natural texture, rich texture changes, highlighting the natural style of solid wood flooring. International home decoration is now popular color difference is huge, long and short, different kinds of materials. With the enhancement of the environmental consciousness of consumers in our country, it is bound to be in the decoration style.

- Q: Solid wood flooring is also strengthened as there are several layers of it? What role

- The service life in public places will not be more than six months.The more abrasive, the price is also more expensive. Public places the level of abrasion resistance at 9000 rpm and above; if the population in your home, also do not pay attention to maintenance, can choose some high wear resistance; but if you pay more attention to the maintenance of the floor, the floor is strong, hardware wear fewer opportunities, choose a relatively low wear resistance may be more economic benefits. Household wear-resisting revolution in 6000 turn above.. Use sandpaper brush, poor quality is very easy to find. Wear resistance of the composite floor, mainly depends on three oxidation of two aluminum (commonly known as precious stones) coating. The higher the content of the three aluminum oxide crystal per unit area is, the higher the degree of wear resistance is.

Send your message to us

Embossed Surface Laminated Flooring with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches