Laminate Flooring

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 X 20'GP m²

- Supply Capability:

- 50 X 20'GP Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Laminate Flooring

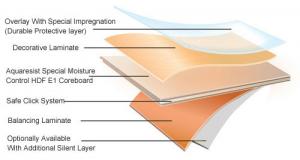

Laminate Flooring mimics the look of traditional woods while offering easy installation and lasting durability. At first glance, it can be difficult to spot the difference between hardwoods and laminate flooring. What appears to be a natural wood grain pattern is really a thin layer of decor paper (a photographic image) under a tough-as-nails protective film that is glued and pressed to a high-density backing board. Laminate flooring comes in an array of wood effects as well as stone and ceramic effects.

Characteristics of Laminate Flooring

· Resistant to UV rays

· Resistant to stains

· Not worn by furniture feet

· Resistant to cigarette burning

· Resistant household chemicals

· Healthy and ecological HDF E1

· Resistant to scratch

· Impact resistant

· Suitable for subfoor heating

AC Rating of Laminate Flooring

Class | 21 | 22 | 23 | 31 | 32 | 33 |

Marks |

|

|

|

|

|

|

Usage | Residential | Commercial | ||||

General | Medium | Heavy | General | Medium | Heavy | |

Grade | AC1 | AC2 | AC3 | AC4 | AC5 | |

EN 13329 | IP≥900 | IP≥1800 | IP≥2500 | IP≥4000 | IP≥6500 | |

GB/T 18102-2000 | IP≥2500 | IP≥4000 | IP≥6000 | IP≥9000 | IP≥11000 | |

Specifications of Laminate Flooring

Thickness | 6mm, 7mm, 8.3mm, 12.3mm, 13.5mm, 15mm |

Width | 93mm, 113mm, 126mm, 145mm, 167mm, 196mm |

Length | 1215mm, 806mm, RL(1210/805/405mm) |

Available Colors | Various designs, more than 200 colors, including Oak, Walnut, Maple, Cherry, Beech, Pine, Teak, Hickory, Merbau, Mahogany, Chestnut, Elm, Alder, Bamboo, etc. |

Available Surface | Crystal, Embossment, Paint Finish, Mirror, Matt, Wood Texture Effect, Handscraped, EIR, etc. |

Wear Resistance | AC2, AC3, AC4 |

Core Type | Moisture resistant HDF |

Edge Style | Square edges, Beveled edges |

Installation | Click system |

Waxing | Available by order |

Padding | Available by order (EVA, EPE...) |

Packing | Standard export packing |

Technical Standard | EN 13329 |

Certificate | ISO9001 / ISO14001 / CE |

- Q: What is the difference between composite wood flooring and laminate flooring?

- Multi layer composite floor is characterized by:1, make full use of precious wood and ordinary small size material, without affecting the surface decoration effect under the premise of reducing the cost of the product, won the customer's favorite;2, the structure is reasonable, warping deformation is small, no cracking, shrinkage phenomenon, with good elasticity;3, large size, easy installation, good stability;4, the decorative effect is good, and the luxury type of solid wood flooring in the appearance of the same effect

- Q: What are the benefits of solid wood flooring decoration

- There are oak, ash, birch, several species of wood floor on the market at present. The physical properties of wood are better than ash, as the market's first material.

- Q: Wood floors and solid wood flooring price difference? Which brand is good

- Solid wood flooring is more expensive than solid wood, solid wood floor maintenance, easy care.. My home is the last year to buy the disc beans 4211 this, buy the floor is reassuring. I was through a series of research, the final choice of the floor

- Q: What are the solid wood floor?

- OakThe utility model has the advantages of distinct mountain wood, and touch the surface with good texture; excellent toughness, according to a variety of curved shape, processing needs of beauty; solid texture, manufactured goods firm structure, long service life; the stability of the floor is relatively good; high grade, suitable for European, Chinese classical style, obvious bulkiness a stately mahogany furniture, but the price is lower than the mahogany furniture.Disadvantages: high quality species is relatively small, hard heavy oak, water clean is difficult, not to take off the water purification production of furniture, a year or may start to deformation or shrinkage cracking. In the market, the phenomenon of replacing oak with rubber wood is common. If the customer's professional knowledge is insufficient, it will directly affect the interests of consumers.

- Q: Can you use a steam cleaner on engineered hardwood floors?

- Yes. Stanley Steamer says so to!

- Q: I am trying to decide on What company to go with as well as two different installers. The brands are Shaw, Mirage & Lauzon. The prices are slightly higher for the Mirage/Lauzon and the installation charge is as well but it's glued & nailed vs. a versa-lock? Just trying to figure out what would be better in a Family Room off of a Kitchen.Thanks

- I am not sure about the brands you named, but we just recently had a hardwood floor installed in our kitchen dining and family room... we picked Mohawk brand, and are very pleased with it. The installation of the 3 rooms we had done were about 1/2 the price of the materials, and was glued down tongue and groove.

- Q: How much aluminum oxide or AO (in weight proportion, or ounces or milligrams) is often in engineered hardwood floor finishes, and how much of the AO is released into the air through normal usage (walking on the floor, typical activities) or if there are small scratches?Is the amount of AO released into the air on such flooring significant versus background AO levels?I realize that sanding/refinishing an engineered floor will release much more AO into the area, but my main concern here is about general household use.Thanks, Michal

- Unless you walk around with sandpaper glued to your shoe soles I doubt there would be any detectable amount released from normal usage. There are certainly far more substances I would be concerned about in a house environment than that. If you are really obsessed about it, contact the flooring manufacturer for data.

- Q: Diamond, laminate flooring and laminate flooring to strengthen what kind of good

- Diamond Board is commonly known as the strengthening of the floor, the standard name for "impregnated paper laminated wooden floor". Laminate flooring is generally composed of four layers of composite material, that is, wear-resistant layer, decorative layer, high-density substrate layer, the balance (moisture) layer

- Q: 1. I live on the 14th floor of a 60 year old building. Would I need a moisture barrier?2. I want to glue hardwood to cork underlayment and float the cork underlayment over the concrete. Is this possible or advisable?

- Most engineered flooring doesn't require a glue down, if you do want to glue it down, you'll have to do it directly to the concrete. You can a concrete sealer as a vapor barrier. I've installed most of these systems using a foam vapor barrier with no fastening, as a floating floor. Good Luck!

- Q: Cork, 2-in-1 or something else? What are the advantages/disadvantages of each? Also, are these types of floors okay for installation in a kitchen?All installation is at or above grade. 30 year-old home with concrete slab.

- I would strongly suggest that you use the same manufacturer's underlayment. most of them come with attached moisture barrier (or thicker plastic). If not, make sure you install one first since you are installing on concrete slab. I have installed laminate wood on kitchen floors. but I personally prefer tiles in the kitchen, most durable, applicable, and appropriate kind of flooring for kitchen which is subject to extensive use and water contact. If you don't have kids in the house and not too many people, it's alright. I would recommend laminate wood though, very durable and easy to install. good luck!

1. Manufacturer Overview

| Location | Mudanjiang, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | 70.00% North America 10.00% Western Europe 10.00% Middle East 10.00% Domestic |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Dalian |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average; Low |

Send your message to us

Laminate Flooring

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 X 20'GP m²

- Supply Capability:

- 50 X 20'GP Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords