Tabel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

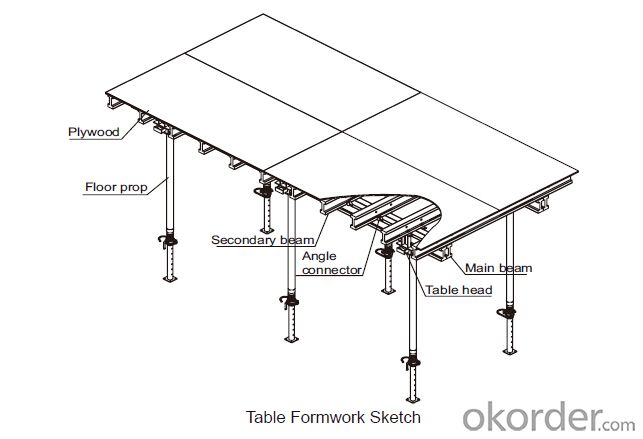

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: How does steel frame formwork prevent concrete segregation or bleeding during pouring?

- There are several ways in which steel frame formwork assists in preventing concrete segregation or bleeding during pouring: 1. Stability is provided by the steel frame, which prevents excessive movement of the formwork while pouring. This reduces the likelihood of concrete segregation, wherein heavier aggregates separate from the cement paste, resulting in an uneven distribution of materials. 2. Additional reinforcement elements, such as steel bars or mesh, are often included in the steel frame formwork. These reinforcements help hold the concrete together and prevent segregation. They also enhance the overall strength and durability of the concrete structure. 3. Steel formwork is designed to fit tightly against the edges of the concrete structure, leaving no gaps or openings. This tight fit restricts the movement of the concrete, minimizing the potential for segregation or bleeding. 4. Compared to other types of formwork materials, steel frame formwork is generally more rigid and resistant to vibrations. This rigidity reduces the likelihood of concrete segregation, as vibrations can cause the aggregates to separate from the cement paste. 5. Steel formwork often features a smooth surface, allowing for better flow and distribution of the concrete during pouring. The absence of rough or uneven surfaces minimizes the risk of segregation, as the concrete can easily flow and settle evenly within the formwork. In summary, steel frame formwork offers stability, reinforcement, a tight fit, vibration resistance, and a smooth surface to prevent concrete segregation or bleeding during pouring. These characteristics ensure a uniform distribution of materials and enhance the strength and quality of the final concrete structure.

- Q: What are the different types of formwork corners used in steel frame formwork systems?

- There are typically two types of formwork corners used in steel frame formwork systems: internal corners and external corners. Internal corners are used when the formwork needs to be supported from the inside, while external corners are used when the formwork needs to be supported from the outside. Both types of corners are designed to provide stability and reinforcement to the formwork structure, ensuring the proper alignment and stability of the concrete during the pouring and curing process.

- Q: Does steel frame formwork require any specific curing methods?

- Steel frame formwork does not require any specific curing methods. Unlike traditional formwork materials such as wood or plywood, steel frame formwork is not affected by moisture or temperature variations. It is a durable and non-absorbent material that does not require any special curing techniques. Once the concrete is poured into the formwork, it will naturally cure and harden on its own, regardless of the type of formwork used. However, it is important to follow standard concrete curing practices, such as providing adequate moisture and temperature control, to ensure proper curing and achieve the desired strength and durability of the final concrete structure.

- Q: Stone curtain wall steel frame in the 90 degree angle of the horizontal frame connection

- Lap welding, if left and right sub grid is relatively large with the column

- Q: How does steel frame formwork affect the overall sustainability certifications of a building?

- Steel frame formwork can significantly impact the overall sustainability certifications of a building in a positive way. One of the key aspects of sustainability is the efficient use of resources, and steel frame formwork excels in this area. Steel is a highly durable and recyclable material, meaning that it can be used repeatedly without compromising its structural integrity. This reduces the need for new materials, minimizing the environmental impact associated with construction. Additionally, steel frame formwork offers enhanced efficiency during the construction process. It allows for faster assembly and disassembly, reducing the time required for construction and minimizing disruption to the surrounding environment. This can lead to reduced energy consumption, as the construction phase is completed more quickly. Furthermore, steel frame formwork provides excellent strength and stability, enabling the construction of taller and larger buildings. This can optimize land use and reduce the footprint of the building, contributing to a more sustainable urban environment. Moreover, steel is resistant to fire, pests, and natural disasters, ensuring the longevity and safety of the building. This reduces the need for frequent repairs and replacements, leading to lower maintenance costs and less waste generation. In terms of sustainability certifications, such as LEED (Leadership in Energy and Environmental Design), steel frame formwork can contribute to earning points in various categories. These certifications often prioritize energy efficiency, materials and resources, and innovation in design. Steel frame formwork can help achieve these goals by reducing energy consumption during construction, utilizing recycled materials, and providing a durable and long-lasting structure. Overall, steel frame formwork positively affects the sustainability certifications of a building by promoting resource efficiency, reducing environmental impact, enhancing construction efficiency, and contributing to the durability and safety of the structure.

- Q: How does steel frame formwork affect the overall sustainability of a construction project?

- Steel frame formwork can significantly enhance the overall sustainability of a construction project in several ways. Firstly, steel is a highly durable material that can be reused multiple times, reducing the need for constant replacements and minimizing waste generation. Additionally, steel frame formwork allows for efficient construction processes, resulting in shorter project durations and decreased energy consumption. Moreover, the use of steel formwork enhances structural integrity, reducing the need for maintenance and repairs in the long run. Lastly, steel is a recyclable material, promoting circular economy principles and reducing the environmental impact of the construction industry.

- Q: How does steel frame formwork accommodate for different concrete pumping methods?

- Steel frame formwork proves to be a versatile and adaptable system capable of effectively accommodating various concrete pumping methods. Its design ensures robustness and stability, facilitating the efficient transfer of forces during the concrete pouring process. A significant advantage of steel frame formwork lies in its ability to withstand the high pressures generated by different concrete pumping methods. Truck-mounted boom pumps, stationary pumps, and line pumps all exert forces during the pumping process, which the steel frame formwork can handle without compromising its structural integrity. Moreover, customization and adjustment options are readily available with steel frame formwork to cater to different concrete pumping methods. The formwork panels can be designed with openings like holes or slots to accommodate pipes and hoses used in the pumping process. This feature ensures smooth and efficient pumping operations, preventing any blockages or hindrances. Additionally, the steel frame formwork system is easily disassembled and reassembled, making it suitable for diverse project requirements and changing pumping methods. This flexibility allows for effortless modifications and adjustments to the formwork system, ensuring it can adapt to any alterations in the concrete pumping method during the construction process. Overall, steel frame formwork proves to be a dependable and adaptable solution for accommodating various concrete pumping methods. Its robust nature, stability, and customization options make it the preferred choice in construction projects where concrete pumping is necessary.

- Q: Can steel frame formwork be used in underground construction projects?

- Indeed, underground construction projects can make use of steel frame formwork. Steel frame formwork is a system that is both versatile and durable, making it a popular choice for a variety of construction applications, including underground projects. Its strength and rigidity enable it to withstand the pressures and forces commonly associated with underground construction. Typically constructed from high-quality steel, steel frame formwork offers excellent structural integrity and resistance to deformation. This quality makes it particularly well-suited for use in underground projects, where the soil and surrounding environment can exert increased levels of pressure. Furthermore, steel frame formwork provides flexibility in design and can be easily customized to meet the specific requirements of underground construction projects. Its adaptability allows for the creation of intricate shapes and structures, which are often necessary in underground constructions such as tunnels, subway systems, and basements. Another advantage of steel frame formwork is its reusability, which can lead to cost savings and reduced environmental impact in underground construction. The formwork can be effortlessly dismantled, relocated, and reassembled in different locations, making it an economical choice for projects that involve multiple construction phases. In conclusion, steel frame formwork is an ideal option for underground construction projects due to its strength, durability, flexibility, and reusability. It provides the necessary structural support and adaptability required to tackle the unique challenges associated with underground construction, making it a preferred choice for many engineers and contractors.

- Q: How does steel frame formwork handle the placement of architectural finishes, such as tiles or cladding, on the concrete structure?

- Steel frame formwork provides a stable and strong framework for the placement of architectural finishes on a concrete structure. The formwork system ensures precise alignment and support, allowing for the accurate installation of tiles or cladding. Additionally, the steel frame formwork can be easily adjusted or modified to accommodate different finishes, ensuring flexibility and efficiency in the construction process.

- Q: What are the different types of formwork joints used with steel frame formwork?

- Steel frame formwork can be used with various types of formwork joints to ensure the stability and strength of the system during the concrete pouring process. Some commonly used joints include the butt joint, corner joint, T-joint, L-joint, Y-joint, slip joint, and key joint. The butt joint is the simplest joint, joining two panels end to end and is suitable for straight walls or columns. The corner joint connects two panels at a corner, providing stability and maintaining the desired shape. The T-joint forms a T-shape where three panels meet and is ideal for connecting intersecting walls. The L-joint, similar to the T-joint, connects two panels at a 90-degree angle, forming an L-shape, commonly used for walls or columns. The Y-joint is used for branching walls or columns, creating a Y-shape and ensuring concrete containment. The slip joint allows for movement between panels and is used in situations where thermal expansion or contraction may occur. The key joint creates a keyway in the concrete, transferring loads between adjacent pours and is commonly used in large-scale projects. Each joint serves a specific purpose and is selected based on the construction requirements. Proper installation and use of these joints are crucial for maintaining the stability and integrity of the formwork system and the resulting concrete structure.

Send your message to us

Tabel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords