Tabel Formwork for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

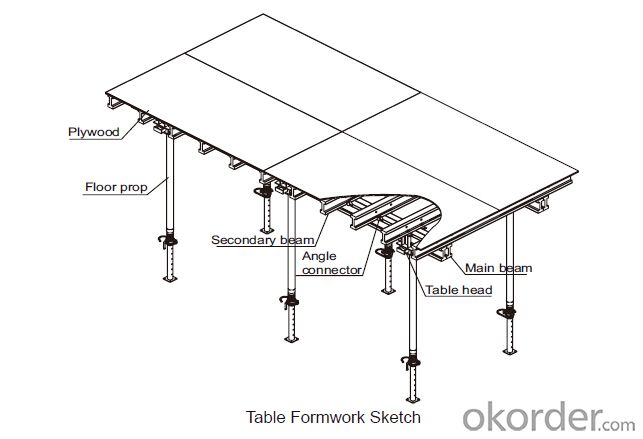

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: How does steel frame formwork handle different types of formwork joint arrangements?

- With its versatility and durability, steel frame formwork effortlessly handles a variety of formwork joint arrangements. This adaptable formwork is designed to be flexible, accommodating different configurations and combinations of joints. One commonly used joint arrangement is the butt joint, where two formwork panels meet end-to-end. Steel frame formwork is specifically designed with special connectors and clamps that securely hold the panels together, ensuring a seamless joint. These connectors are adjustable, allowing for precise alignment of the panels to achieve the desired formwork shape and dimensions. Another joint arrangement is the corner joint, where two formwork panels meet at a 90-degree angle. Steel frame formwork is equipped with corner connectors that securely hold the panels together at the desired angle. These connectors are also adjustable, ensuring a strong and stable corner joint. In addition to butt and corner joints, steel frame formwork can also handle other joint arrangements such as T-joints, cross joints, and Y-joints. The adjustable connectors and clamps of steel frame formwork make it easy to assemble and disassemble the panels, allowing for various joint configurations as required by the specific formwork design. Moreover, steel frame formwork offers excellent stability and load-bearing capacity, making it suitable for even the most complex and demanding construction projects. The steel frames and panels are designed to withstand the pressure and forces exerted during the concrete pouring and curing process, ensuring the durability and strength of the formwork joints. Overall, steel frame formwork is a dependable and efficient system that can handle diverse formwork joint arrangements. Its adjustable connectors and clamps, along with its stability and load-bearing capacity, make it the preferred choice for a wide range of construction applications.

- Q: How is steel frame formwork assembled?

- Construction projects commonly utilize steel frame formwork to create concrete walls, columns, beams, and slabs. The process of assembling steel frame formwork involves multiple steps. Firstly, the construction site must be prepared before the steel frame formwork is assembled. This involves tasks such as leveling the ground, removing debris, and implementing necessary safety measures. Next, the layout and dimensions of the concrete structure are marked on the ground or wall where the formwork will be installed. This step ensures accurate placement of the steel frames. Vertical supports are then erected to provide stability and strength to the formwork. These supports, typically made of steel or aluminum, are secured to the ground or wall using bolts or anchors. Horizontal beams are installed and connected to the vertical supports to create the frame structure. These beams are positioned according to the marked layout and secured in place using connectors or clamps. Following the installation of the frame structure, plywood panels are attached to the steel frame using screws or nails. These panels serve as the surface upon which the concrete will be poured and formed. The size and thickness of the plywood depend on the project's specific requirements. Reinforcement and bracing are added to the formwork to ensure stability during the concrete pouring process. This can include diagonal braces, tie rods, and cross beams that provide extra support and prevent movement or deformation. Once the steel frame formwork is assembled, it is thoroughly checked for any gaps, misalignments, or loose connections. Any issues are promptly rectified to ensure a tight and secure formwork structure. Any necessary adjustments or modifications are made at this stage. Overall, the assembly of steel frame formwork necessitates meticulous planning, precise measurements, and proper installation techniques. It is crucial to adhere to the manufacturer's instructions and comply with safety guidelines to ensure a successful and safe construction process.

- Q: Are there any specific considerations for using steel frame formwork in heritage buildings?

- Yes, there are specific considerations for using steel frame formwork in heritage buildings. The use of steel frame formwork should be carefully evaluated in order to avoid any potential damage to the historic fabric of the building. It is important to ensure that the steel frame is compatible with the existing structure and does not compromise its integrity or aesthetics. Additionally, the installation process should be carried out by experienced professionals who are familiar with the unique requirements of heritage buildings.

- Q: What are the key considerations for selecting the appropriate steel frame formwork supplier for international projects?

- When selecting the appropriate steel frame formwork supplier for international projects, there are several key considerations that should be taken into account. Firstly, it is important to assess the supplier's experience and track record in working on international projects. This includes evaluating their previous projects, particularly those that are similar in scale and scope to the project at hand. A supplier with a proven track record in successfully delivering international projects will likely have the necessary expertise and understanding of the specific requirements and challenges that may arise. Secondly, it is crucial to consider the supplier's ability to meet international standards and regulations. Different countries may have varying building codes and regulations that need to be adhered to, so it is essential that the supplier has experience in complying with these standards. This can help to ensure that the steel frame formwork supplied is of high quality and meets all necessary safety requirements. Additionally, the supplier's capacity to handle logistics and transportation for international projects should also be taken into account. This includes evaluating their ability to deliver the formwork to the project site in a timely manner, as well as their understanding of any customs and import/export requirements that may be involved. A supplier with a well-established network and efficient logistical capabilities can help to minimize delays and ensure smooth operations throughout the project. Furthermore, it is important to consider the supplier's after-sales support and technical assistance. International projects may require troubleshooting and technical guidance, so it is crucial that the supplier offers reliable support and assistance throughout the project duration. This can include providing training for onsite personnel, offering prompt responses to queries, and having a dedicated team to handle any issues that may arise. Lastly, the cost-effectiveness of the supplier's offerings should be evaluated. While it is essential to prioritize quality and reliability, it is also important to ensure that the supplier's pricing is competitive and aligns with the project's budget. This can be done through requesting detailed quotations and comparing them with other suppliers in the market. In conclusion, selecting the appropriate steel frame formwork supplier for international projects requires careful consideration of factors such as experience, compliance with international standards, logistical capabilities, after-sales support, and cost-effectiveness. By thoroughly assessing these key considerations, project stakeholders can make an informed decision and choose a supplier that is best suited to meet the project's requirements.

- Q: What are the key considerations for selecting the appropriate steel frame formwork rental company?

- When choosing a suitable steel frame formwork rental company, it is important to keep in mind several important factors. These factors can help guarantee that you select a dependable and respected company that will meet your specific requirements. 1. Experience and Expertise: It is advisable to search for a rental company that has a proven track record and extensive experience in offering steel frame formwork solutions. Their expertise will ensure that they comprehend your project needs and can provide the appropriate equipment and assistance. 2. Variety of Equipment: Verify whether the rental company offers a wide range of steel frame formwork options. This will enable you to choose the most suitable formwork system for your project, enhancing efficiency and cost-effectiveness. 3. Equipment Quality: Evaluate the quality of the steel frame formwork equipment provided by the rental company. Ensure that it is made from high-quality materials and meets industry standards. This will help guarantee the safety and durability of the formwork at your construction site. 4. Maintenance and Support: Inquire about the maintenance and support services provided by the rental company. The equipment should undergo regular inspections and maintenance to prevent any issues during your project. Additionally, the company should offer technical support and assistance in case of any problems or queries. 5. Availability and Delivery: Take into account the availability of the steel frame formwork equipment you require. Make sure that the rental company has sufficient stock to meet your project timeline. Also, inquire about their delivery options and whether they can accommodate any specific requirements you may have. 6. Pricing and Contracts: Compare the prices of different rental companies to ensure that you are receiving a fair and competitive rate. Additionally, carefully review the rental contract to understand the terms and conditions, including payment terms, duration, and any additional fees. 7. Customer Reviews and References: Examine customer reviews and testimonials to gain insights into the rental company's reputation and customer satisfaction. Request references from the rental company and contact previous clients to obtain firsthand feedback on their experience. By considering these essential factors, you can choose a suitable steel frame formwork rental company that will provide you with the necessary equipment, support, and expertise to ensure the success of your construction project.

- Q: Steel frame wood template defects

- And out of the wall also need high cost in the batch. Turnover number is not much

- Q: What are the different finishes that can be achieved with steel frame formwork?

- Some of the different finishes that can be achieved with steel frame formwork include smooth, textured, patterned, and imprinted surfaces.

- Q: Can steel frame formwork be used in earthquake-prone regions?

- Yes, steel frame formwork can be used in earthquake-prone regions. Steel is a strong and durable material that can withstand seismic forces better than other materials like wood or concrete. Steel frame formwork systems are designed to be rigid and robust, providing stability and resistance to shaking during an earthquake. Moreover, steel frame formwork can be easily assembled and disassembled, allowing for quick construction and minimizing the time workers spend in potentially hazardous areas. This can be a crucial advantage in earthquake-prone regions where rapid construction is needed to rebuild damaged structures. Additionally, steel frame formwork can be reinforced with additional bracing and supports to further enhance its seismic resistance. This can be especially important in areas with high seismic activity, where buildings need to be designed to withstand strong ground motions. However, it is important to note that while steel frame formwork can provide a higher level of earthquake resistance compared to other materials, it is still necessary to follow specific design and construction guidelines to ensure the safety and stability of the structures. Consulting with structural engineers and adhering to local building codes and regulations is essential to ensure the proper use and implementation of steel frame formwork in earthquake-prone regions.

- Q: Can steel frame formwork be used for both vertical and horizontal concrete elements?

- Indeed, it is possible to utilize steel frame formwork for both vertical and horizontal concrete elements. This versatile and enduring system can be effortlessly assembled and modified to accommodate a diverse range of concrete structures of different shapes and sizes. The steel frames offer ample strength and stability to withstand the weight and pressure exerted by the wet concrete during pouring and curing. Consequently, it is a fitting choice for the construction of walls, columns, beams, slabs, and other concrete elements, whether they are positioned vertically or horizontally. The employment of the steel frame formwork system facilitates prompt and efficient construction, ensuring exceptional quality outcomes while simultaneously reducing construction time and expenses.

- Q: Are there any restrictions on the thickness of the concrete that can be poured using steel frame formwork?

- Yes, there are restrictions on the thickness of concrete that can be poured using steel frame formwork. The thickness usually depends on the design and specifications of the steel formwork system being used. It is important to consult the manufacturer or design engineer to determine the maximum recommended thickness for pouring concrete using steel frame formwork.

Send your message to us

Tabel Formwork for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords