new plastic formworks used in construction industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Main Introduction of Plastic Formwork:

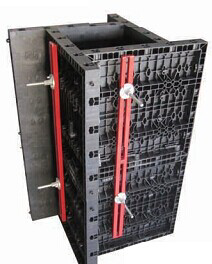

Hot rolled deformed steel framework. the peripheral board is made of FRTP plastic template and add some steel ribssupporting the panel welding a new type of industrialization combined template.which is mainl. The biggest panel is 120x60cm, weight only 10.5kg, which can be lift and set up by only one person easily, need no crane on the site.

2. The Advantages of Plastic Formwork:

-easy set up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the

system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

-modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls

and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls120x60 panel (act size 120x60cm) of multiple by 5cm. The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures.

-strength

The handles are made by high strength Nilon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

-enviroment friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment.

-consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

3. Images for Plastic Formwork:

4. FAQ of Plastic Formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in plastic formwork, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

- Q: What is the weight of steel frame formwork panels?

- The size and thickness of steel frame formwork panels can cause variations in their weight. Typically, these panels weigh approximately 20-30 kilograms per square meter. Nevertheless, it should be emphasized that this weight may vary according to specific design specifications and the steel type employed in panel construction.

- Q: Can steel frame formwork be used for both straight and curved slabs?

- Yes, steel frame formwork can be used for both straight and curved slabs. The steel frames can be easily adjusted to create the desired shape and can withstand the pressure of concrete, making it a versatile option for various slab designs.

- Q: What are the main components of a steel frame formwork system?

- The main components of a steel frame formwork system include steel panels, connecting brackets, adjustable props, form ties, and accessories such as stop-end brackets and joint pins.

- Q: Can steel frame formwork be used in areas with limited access to utilities?

- Yes, steel frame formwork can be used in areas with limited access to utilities. Unlike traditional formwork systems that require water and electricity for setup and removal, steel frame formwork is designed to be easily assembled and disassembled without the need for additional utilities. It is a versatile and portable solution that can be used in remote locations or areas where access to utilities is limited. Steel frame formwork is typically lightweight and can be transported to the site manually or with minimal machinery, making it suitable for areas with limited infrastructure. Additionally, steel frame formwork can be reused multiple times, reducing the need for constant supply of utilities during construction. Overall, steel frame formwork provides a practical and efficient solution for construction projects in areas with limited access to utilities.

- Q: Can steel frame formwork be used in projects with limited construction site waste management facilities?

- Yes, steel frame formwork can be used in projects with limited construction site waste management facilities. Steel frame formwork is a durable and reusable system that can significantly reduce construction site waste. Unlike traditional timber formwork, which is often discarded after each use, steel frame formwork can be used multiple times, reducing the amount of waste generated on the construction site. Additionally, steel frame formwork can be easily dismantled and transported to another location, further reducing waste. Therefore, using steel frame formwork in projects with limited construction site waste management facilities can help minimize waste and improve sustainability.

- Q: Can steel frame formwork be used for both horizontal and vertical concrete structures?

- Steel frame formwork is capable of being utilized for both horizontal and vertical concrete structures. It is a system that is versatile and long-lasting, and can be effortlessly put together and taken apart, making it appropriate for a range of construction projects. This system furnishes the concrete with a solid and inflexible support during the pouring and curing process, guaranteeing appropriate alignment and stability for both horizontal slabs and vertical walls. Moreover, steel frame formwork enables precise adjustment and customization to adapt to various shapes and sizes of structures. Its sturdy construction and ability to endure high pressure and load make it an excellent choice for both horizontal and vertical concrete structures.

- Q: How is the steel frame formwork secured to the ground?

- The steel frame formwork is typically secured to the ground through several methods. One common method is by using ground anchors or stakes, which are driven into the ground and attached to the formwork. These anchors provide stability and prevent the formwork from shifting or moving during the concrete pouring and curing process. Additionally, the formwork can be further secured by using tie rods or braces that connect the formwork to nearby structures or anchor points, ensuring it remains firmly in place. The specific method of securing the steel frame formwork to the ground may vary depending on the project's requirements and the soil conditions at the construction site.

- Q: Can steel frame formwork be used in areas with limited site preparation?

- Areas with limited site preparation can effectively utilize steel frame formwork. This system is versatile and robust, easily accommodating different project requirements. Unlike traditional timber formwork, steel frame formwork does not necessitate extensive site preparation, such as ground leveling or compacting. The lightweight steel frames can be conveniently transported to the site, making them ideal for areas with limited access or challenging terrain. Moreover, the flexibility of steel frame formwork allows for easy adjustment to uneven surfaces or irregular shapes, which is particularly advantageous in areas where site preparation may be difficult. Additionally, steel frame formwork provides exceptional strength and durability, rendering it suitable for use in areas with limited site preparation. The steel frames are specifically designed to withstand heavy loads and offer stability to the formwork, ensuring the safety and efficiency of the construction process. In summary, steel frame formwork is a highly effective option in areas with limited site preparation due to its adaptability, versatility, and strength. Its ability to easily adjust to varying project requirements and withstand heavy loads makes it a suitable choice for diverse construction projects, regardless of site conditions.

- Q: Can steel frame formwork be used for wastewater treatment plants?

- Yes, steel frame formwork can be used for wastewater treatment plants. Steel is a durable and robust material that can withstand the harsh conditions and corrosive environment commonly found in wastewater treatment plants. It provides strength and stability necessary for the construction of various structures and components in such facilities.

- Q: How does steel frame formwork handle concrete shrinkage and expansion?

- To accommodate concrete shrinkage and expansion, steel frame formwork is engineered with the necessary flexibility and strength. It addresses shrinkage by utilizing adjustable mechanisms that allow for slight movements and adjustments in the formwork. These mechanisms, such as telescopic struts or adjustable props, can be easily modified to compensate for shrinkage and maintain the desired form and shape of the concrete structure. In contrast, concrete expansion can arise from factors like temperature changes or moisture absorption. Steel frame formwork is designed to withstand these expansion forces while upholding the structure's integrity. The steel frames are rigid and provide the essential strength and support to resist the expansion forces exerted by the concrete. Additionally, steel frame formwork can incorporate expansion joints, which serve as flexible connections between different sections of the formwork. These joints enable controlled movement and expansion of the concrete, reducing the risk of cracks or damage. In summary, steel frame formwork is purposefully constructed to handle concrete shrinkage and expansion by offering flexibility, adjustability, and strength. This ensures the stability and security of the formwork during the curing process, ultimately resulting in a structurally sound and long-lasting concrete structure.

Send your message to us

new plastic formworks used in construction industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches