Tabel formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

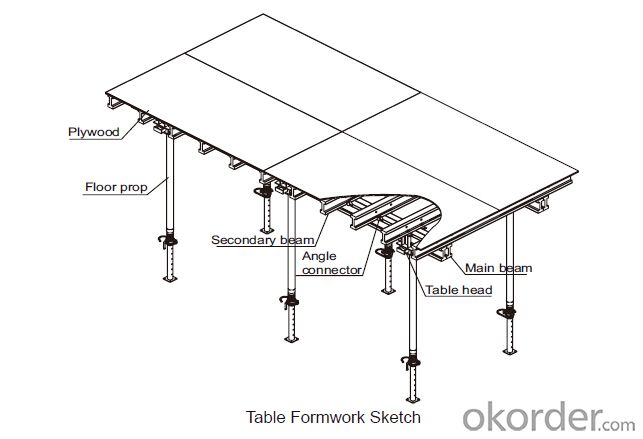

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: Can steel frame formwork be used for both interior and exterior concrete elements?

- Yes, steel frame formwork can be used for both interior and exterior concrete elements. Steel frame formwork provides excellent strength and durability, making it suitable for various construction applications. It can effectively hold the weight and pressure of concrete, ensuring a smooth and efficient construction process for both interior and exterior concrete elements.

- Q: How is steel frame formwork dismantled after concrete curing?

- After the concrete has cured, the dismantling process of steel frame formwork begins. This process generally involves several steps to ensure the safe and efficient removal of the formwork. 1. Inspection: Before dismantling, a thorough inspection of the concrete structure is conducted to ensure that it has achieved the required strength and stability. This inspection is critical to avoid any potential damage to the structure during dismantling. 2. Removal of Props: The first step in dismantling is to remove the props that were used to support the formwork during the concrete pouring and curing process. This is done carefully to prevent any sudden movement or collapse of the structure. 3. Stripping of Formwork Panels: The formwork panels used for shaping the concrete are then removed. This is usually done by loosening the clamps or bolts that hold the panels together. Care is taken to prevent any damage to the panels, as they may be reused for future projects. 4. Removal of Shuttering and Accessories: Once the formwork panels are removed, the shuttering and other accessories such as wedges, ties, and pins are taken down. These accessories are carefully collected and stored for reuse or recycling. 5. Cleaning and Maintenance: After the formwork is completely dismantled, the surface of the concrete structure is cleaned to remove any debris or residue left behind by the formwork. This cleaning process ensures a smooth and clean finish for the structure. 6. Storage or Disposal: Depending on the condition and quality of the dismantled formwork components, they may be stored for future use in other construction projects. If the components are damaged or no longer suitable for reuse, they are properly disposed of or recycled in accordance with environmental regulations. Overall, the dismantling of steel frame formwork after concrete curing requires careful planning, inspection, and execution to ensure the safety and integrity of the structure. Following the appropriate procedures, the process can be carried out efficiently, allowing for the completion of the construction project.

- Q: How does steel frame formwork accommodate for changes in concrete temperature?

- Steel frame formwork accommodates for changes in concrete temperature by being able to expand and contract without compromising the structure’s integrity. This is possible because steel has a high coefficient of thermal expansion, allowing it to adjust with the expansion and contraction of the concrete as it experiences temperature variations. Additionally, steel frame formwork is designed to provide proper spacing and support for concrete pouring, which further helps to minimize any potential issues caused by temperature changes.

- Q: How does steel frame formwork contribute to the overall acoustics of a structure?

- Steel frame formwork does not directly contribute to the overall acoustics of a structure. However, it can indirectly impact acoustic performance by providing a solid and sturdy framework for other acoustic materials, such as insulation or soundproofing panels, to be installed.

- Q: Is steel frame formwork suitable for both residential and commercial construction projects?

- Steel frame formwork is an ideal option for residential and commercial construction projects. With its versatility and durability, this system offers exceptional support and stability during the pouring and curing of concrete. Its design enables it to withstand heavy loads and be effortlessly adjusted and reused for multiple projects. Moreover, steel frame formwork guarantees precise and accurate construction, resulting in a high-quality final structure. Furthermore, its easy assembly and disassembly allow for faster construction, saving valuable time and reducing labor expenses. In conclusion, steel frame formwork is a trustworthy choice for both residential and commercial construction endeavors.

- Q: How does steel frame formwork help in reducing formwork assembly time?

- There are several ways in which formwork assembly time can be reduced with the help of steel frame formwork. To begin with, steel frame formwork is designed to be lightweight and easily adjustable, making it quick and convenient to assemble. The steel frames are typically pre-fabricated and can be easily connected together, allowing for rapid installation. This eliminates the need for complex and time-consuming assembly processes, such as cutting and shaping wooden formwork. Furthermore, steel frame formwork is highly durable and can be reused multiple times. This saves time and effort as the same frames can be used for multiple projects. In contrast, traditional wooden formwork often needs to be built from scratch for each project, increasing the overall assembly time. Moreover, steel frame formwork provides excellent stability and support, reducing the need for additional bracing and support systems. This saves time during assembly as there is no need to spend extra effort on reinforcing the formwork structure. The strong and rigid steel frames can withstand the pressure of the concrete, reducing the risk of formwork failure during the pouring process and minimizing the time spent on repairs or adjustments. Additionally, steel frame formwork allows for efficient and precise concrete pouring. The frames are designed with accurate dimensions, ensuring proper alignment of the formwork. This eliminates the need for extensive adjustments during the pouring process, saving time and reducing the risk of errors. The precise alignment also enables faster removal of the formwork after the concrete has cured, further reducing the overall assembly time. In conclusion, steel frame formwork contributes to a faster and more efficient construction process by offering a lightweight and easily adjustable design, durability for multiple uses, stability and support, and efficient concrete pouring capabilities. These features result in reduced formwork assembly time, ultimately improving overall productivity.

- Q: Can steel frame formwork be used for retail and commercial buildings construction?

- Yes, steel frame formwork can be used for retail and commercial buildings construction. Steel frame formwork is known for its durability, strength, and ability to handle heavy loads, making it suitable for large-scale construction projects. It provides stability and precision in forming concrete structures, ensuring the quality and integrity of the building. Additionally, steel frame formwork offers flexibility in design and can be easily adjusted to accommodate different architectural requirements.

- Q: Can steel frame formwork be used for both temporary and permanent column construction?

- No, steel frame formwork is typically used for temporary column construction as it can be easily assembled and dismantled. For permanent column construction, other materials like reinforced concrete are commonly used.

- Q: Can steel frame formwork be used for the construction of commercial buildings?

- Yes, steel frame formwork can be used for the construction of commercial buildings. Steel frame formwork consists of steel panels and frames that are designed to provide support and shape to the concrete structure during the construction process. It offers several advantages for commercial building construction. Firstly, steel frame formwork is highly durable and can withstand the pressures and stresses associated with large-scale commercial projects. It has a longer lifespan compared to other types of formwork, making it a cost-effective choice in the long run. Secondly, steel frame formwork is highly adaptable and can be easily customized to meet the specific needs and requirements of commercial building projects. It allows for flexibility in design, enabling architects and engineers to create complex structures and unique architectural features. Furthermore, steel frame formwork provides excellent stability and support, ensuring the structural integrity of the building during and after construction. It can handle heavy loads and is capable of withstanding adverse weather conditions, making it suitable for commercial buildings that require strength and durability. Additionally, steel frame formwork offers faster construction times compared to traditional formwork methods. The prefabricated steel panels can be easily assembled and disassembled, allowing for efficient and streamlined construction processes. This can result in significant time and cost savings for commercial building projects. In conclusion, steel frame formwork is indeed a suitable choice for the construction of commercial buildings due to its durability, adaptability, stability, and efficiency. It provides the necessary support and shape for concrete structures, ensuring the successful completion of large-scale projects.

- Q: How does steel frame formwork compare to other types of formwork in terms of durability?

- Steel frame formwork is widely regarded as one of the most durable types of formwork available in the construction industry. Unlike traditional wooden formwork or other temporary formwork systems, steel frame formwork is built to withstand the demanding pressures of concrete pouring and ensure the longevity of the structure being constructed. The durability of steel frame formwork can be attributed to its robust construction and high-quality materials. Steel frames are typically made from strong and corrosion-resistant materials, such as steel or aluminum alloys. These materials are known for their exceptional strength-to-weight ratios, ensuring that the formwork can withstand the weight and pressure of the concrete without bending or warping. Furthermore, steel frame formwork is designed to be reusable, making it a cost-effective solution for multiple construction projects. The steel frames can be easily disassembled and reassembled, allowing for efficient use on different sites and reducing the need for constant replacement. This reusability factor significantly contributes to the durability of steel frame formwork, as it eliminates the wear and tear associated with single-use formwork systems. In terms of durability, steel frame formwork outperforms other types of formwork, such as wooden formwork or plastic-based systems. Wooden formwork is prone to deterioration due to moisture, rot, and insects, leading to frequent repairs or replacements. On the other hand, plastic-based formwork may be susceptible to thermal expansion and contraction, potentially compromising the integrity of the concrete structure. In conclusion, steel frame formwork excels in terms of durability when compared to other types of formwork. Its robust construction, high-quality materials, and reusability make it a reliable and long-lasting solution for concrete construction projects.

Send your message to us

Tabel formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords