Tabel formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

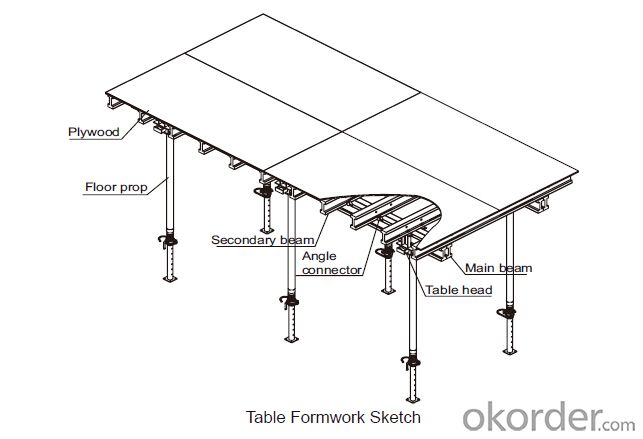

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: Can steel frame formwork be used for both indoor and outdoor construction?

- Steel frame formwork is capable of being used for construction both indoors and outdoors. It is a flexible and long-lasting option that can endure the different circumstances and elements found in both indoor and outdoor surroundings. Its stability and strength, provided by the steel frame, make it appropriate for utilization in various construction undertakings. Furthermore, steel frame formwork presents benefits such as simple assembly, the capability for reuse, and the capacity to produce intricate shapes and structures. In conclusion, steel frame formwork is a dependable alternative that can be employed in a broad array of construction environments.

- Q: Can steel frame formwork be used for power plant structures?

- Yes, steel frame formwork can be used for power plant structures. Steel frame formwork is a versatile and durable construction method that can be used for various types of structures, including power plants. The strength and rigidity of steel make it suitable for the heavy loads and high temperatures often associated with power plant structures. Steel frame formwork offers several advantages for power plant construction. Firstly, it provides excellent structural integrity, ensuring the stability and safety of the power plant. Steel is a strong material that can withstand the weight and stress of large power generation equipment and structures. Additionally, steel frame formwork allows for flexibility in design and construction. It can be easily customized to accommodate the specific requirements of power plant structures, such as the need for large open spaces, high ceilings, and complex layouts. Steel can also be easily modified or expanded if there is a need for future expansion or upgrades in the power plant. Moreover, steel frame formwork offers faster construction times compared to traditional methods. The prefabricated nature of steel components allows for quick and efficient assembly, reducing construction time and costs. This is especially important in power plant projects, where timely completion is crucial to meet energy demands. In conclusion, steel frame formwork can definitely be used for power plant structures due to its strength, durability, flexibility, and efficiency. It provides a reliable construction method for power plants, ensuring the safety, functionality, and longevity of these critical infrastructure projects.

- Q: How does steel frame formwork handle concrete pouring in rainy weather conditions?

- Even in rainy weather conditions, steel frame formwork proves to be a highly dependable and strong construction system that effectively handles concrete pouring. The design of the steel frame provides the necessary support and stability to the formwork, enabling it to withstand the pressure and weight of wet concrete. To shield the concrete from direct contact with water during rainy weather, a waterproof membrane or tarp is typically used to cover the steel frame formwork. This precautionary measure prevents the concrete from becoming diluted or washed away by rain, which could compromise the structure's quality and strength. Furthermore, the tight joints and connections of the steel frame formwork minimize the risk of water seeping into the formwork. This ensures that the concrete maintains its integrity and shape during the pouring process. The rigid structure of the steel frame also prevents any deformation or movement of the formwork, guaranteeing accurate and even pouring of the concrete. In addition, the steel frame formwork system is designed with proper drainage channels and outlets to divert excess water away from the concrete. This prevents water accumulation and ensures that the concrete sets properly without any water-related issues such as voids or weak spots. In conclusion, steel frame formwork is a reliable choice for concrete pouring in rainy weather conditions. Its strong construction, waterproofing measures, and efficient drainage system work together to maintain the quality and integrity of the concrete, resulting in a successful and durable construction project.

- Q: Glass partition, square box outsourcing 1mm thick stainless steel, glass middle is how to set the quota

- Then anchored in the wall! Can be considered to increase the safety factor

- Q: Can steel frame formwork be used for both straight and sloped concrete elements?

- Yes, steel frame formwork can be used for both straight and sloped concrete elements. Steel frame formwork is a versatile and flexible system that can be adjusted to accommodate various shapes and angles. It consists of steel panels that are connected together to create the desired formwork shape. The panels can be easily adjusted to form straight or sloped concrete elements by using adjustable connectors or hinges. This makes steel frame formwork suitable for applications where different angles and shapes are required, such as in construction projects involving curved walls, ramps, or sloped floors. Additionally, the strength and durability of steel make it suitable for supporting the weight and pressure exerted by the concrete during the casting and curing process. Overall, steel frame formwork is a reliable and adaptable solution for both straight and sloped concrete elements.

- Q: Can steel frame formwork be used for both straight and sloped structures?

- Yes, steel frame formwork can be used for both straight and sloped structures. Steel frame formwork is a versatile system that can be easily adjusted to accommodate different angles and slopes. It provides a stable and sturdy support for concrete pouring, ensuring accurate and precise construction of both straight and sloped structures. The steel frame can be easily assembled and disassembled, allowing for flexibility and adaptability in construction projects with varying requirements. Overall, steel frame formwork is an effective solution for constructing both straight and sloped structures.

- Q: Is steel frame formwork suitable for the construction of bridges?

- Yes, steel frame formwork is suitable for the construction of bridges. Steel frame formwork is a type of temporary mold or structure that is used to support and shape concrete during the construction process. It is made from steel and has a strong and durable structure that can withstand the weight and pressure exerted by the concrete. Bridges require a high level of strength and stability, and steel frame formwork provides these qualities. The steel frame can be easily assembled and disassembled, allowing for flexibility and efficiency in constructing various bridge designs. It can also be adjusted to accommodate different shapes and sizes of bridges, making it a versatile option for bridge construction projects. Additionally, steel frame formwork offers a smooth and consistent finish, which is important for bridges as they need to be aesthetically pleasing and safe for vehicles and pedestrians. The use of steel frame formwork also reduces the need for traditional timber formwork, which can be expensive and time-consuming to install and remove. Overall, steel frame formwork is a suitable choice for the construction of bridges due to its strength, durability, flexibility, and efficiency.

- Q: Can steel frame formwork be used for educational and institutional buildings construction?

- Educational and institutional buildings can benefit greatly from the use of steel frame formwork. This construction method is versatile and durable, making it a popular choice for various types of structures. One advantage of steel frame formwork is its strength and reliability. It can withstand heavy loads and provide structural stability, which is particularly important in buildings where the safety of occupants is a priority. Another advantage is the flexibility it offers in design and construction. Steel frame formwork can be easily adjusted and modified to meet different architectural requirements and functional needs. This is especially beneficial in educational buildings, where spaces like classrooms and laboratories may need to be reconfigured or expanded in the future. In addition, steel frame formwork is a time-efficient construction method. The prefabricated steel frames can be quickly assembled on-site, reducing overall construction time. This is crucial in educational and institutional buildings, where strict deadlines must be met, such as the start of a new academic year or the opening of a new facility. In conclusion, steel frame formwork is an efficient and suitable construction method for educational and institutional buildings. Its strength, flexibility, and time-saving qualities make it an ideal choice for these types of structures.

- Q: How does steel frame formwork handle the placement of reinforcement bars?

- Steel frame formwork is a versatile system that allows for easy handling and placement of reinforcement bars. The formwork is designed with pre-determined openings and slots, which provide convenient spaces for the positioning of reinforcement bars. These openings ensure accurate placement, alignment, and spacing of the bars, resulting in a sturdy and durable structure. Additionally, the steel frame formwork provides a stable and secure platform for workers to efficiently install the reinforcement bars, ensuring their proper integration with the formwork system.

- Q: What are the disadvantages of using steel frame formwork?

- One disadvantage of using steel frame formwork is its high initial cost. Steel frame formwork is generally more expensive to purchase or rent compared to other types of formwork materials such as wood or aluminum. Additionally, steel frame formwork requires skilled labor and expertise for its installation and dismantling, which can add to the overall project costs. Another disadvantage is its weight, which makes it more difficult to handle and transport compared to lighter materials. Finally, steel frame formwork may require frequent maintenance to prevent rust and corrosion, which can be time-consuming and costly.

Send your message to us

Tabel formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords