Tabel Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

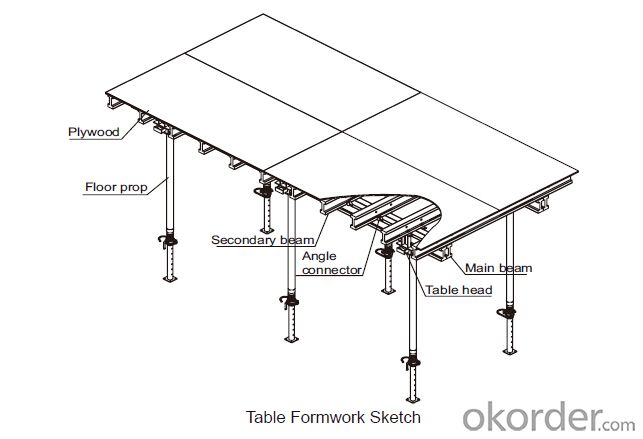

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: How does steel frame formwork affect the overall dimensional accuracy of a concrete structure?

- Steel frame formwork can have a significant impact on the overall dimensional accuracy of a concrete structure. The use of steel frame formwork provides a rigid and sturdy framework that helps maintain the desired shape and dimensions of the structure during the pouring and curing process. One of the main advantages of steel frame formwork is its ability to resist deformation and maintain stability. This means that the formwork will not warp or distort under the pressure of the concrete, ensuring that the structure maintains its intended shape and dimensions. This is particularly important for structures with complex geometries or specific dimensional requirements. Additionally, steel frame formwork allows for precise adjustments and alignment during the construction process. The formwork can be easily adjusted to ensure that all dimensions are accurate and meet the design specifications. This level of precision is crucial for structures that require tight tolerances or have specific dimensional requirements. The use of steel frame formwork also helps to minimize the occurrence of common issues such as formwork deflection or bulging, which can negatively impact the dimensional accuracy of the structure. The rigidity and strength of the steel frame formwork prevent any unwanted movement or deformation, ensuring that the concrete cures evenly and maintains its intended shape. Overall, steel frame formwork significantly enhances the overall dimensional accuracy of a concrete structure. Its rigidity, stability, and ability to resist deformation allow for precise adjustments and alignment during construction, minimizing the risk of dimensional errors. By providing a solid framework, steel frame formwork ensures that the final structure meets the desired shape and dimensions as per the design specifications.

- Q: Can steel frame formwork be used for both indoor and outdoor construction?

- Yes, steel frame formwork can be used for both indoor and outdoor construction. Steel is a versatile and durable material that can withstand various weather conditions, making it suitable for both types of construction projects.

- Q: How long does it take to assemble steel frame formwork?

- The time it takes to assemble steel frame formwork can vary depending on factors such as the size and complexity of the structure, the experience and skill level of the workers, and the availability of necessary equipment. On average, it can take anywhere from a few days to a couple of weeks to complete the assembly process. For smaller structures or simple formwork systems, it may only take a few days to set up and secure the steel frames in place. This involves positioning the frames according to the design specifications, connecting them securely, and ensuring they are level and plumb. Additionally, any necessary adjustments or modifications may need to be made during this stage. On the other hand, for larger or more complex structures, the assembly process can take longer. This is because there may be a greater number of steel frames to install and align, additional bracing and support systems to be incorporated, and more intricate connections to be made. In such cases, it may take several weeks to complete the assembly process, especially if there are any unforeseen challenges or delays. It is important to note that the assembly time mentioned here refers specifically to the steel frame formwork itself and does not include other related tasks such as pouring and curing the concrete, which will add additional time to the overall construction timeline. Ultimately, to determine the exact time it will take to assemble steel frame formwork for a specific project, it is recommended to consult with experienced construction professionals who can assess the project requirements and provide a more accurate estimate.

- Q: Are there any limitations to using steel frame formwork?

- Yes, there are some limitations to using steel frame formwork. One limitation is that steel formwork can be heavy and may require additional equipment for handling and assembly. Additionally, steel formwork may not be suitable for complex or intricate designs as it is less flexible compared to other types of formwork materials. Steel frame formwork can also be more expensive than alternative options, which may not be suitable for projects with tight budgets.

- Q: Are there any limitations to the shape or design of structures that can be constructed using steel frame formwork?

- Steel frame formwork does have limitations in terms of shape and design of structures that can be built. It is a widely used and versatile construction technique, but certain considerations must be made during the design phase. One limitation is the difficulty in constructing curved or irregular shapes. Steel frame formwork works best for structures with straight lines and right angles. Building complex curved or irregular shapes can be challenging and may require customization and additional fabrication. Another limitation is the size and weight of the structure. Steel frame formwork can handle large and tall structures, but there are practical limits to the achievable size and weight. The weight of the formwork and the concrete being poured can strain the steel frames and supports, necessitating careful engineering to maintain structural integrity. Additionally, the height and depth of the structure can be limiting factors. Steel frame formwork systems are typically modular and adjustable, but there are practical limits to the attainable height and depth. Beyond a certain point, additional support systems may be necessary for stability and safety. Lastly, the aesthetic design of the structure may be constrained by the use of steel frame formwork. While finishes and cladding materials can be applied to the formwork, the exposed areas will still have a distinct steel frame appearance. This may not be suitable for certain architectural designs that require a different aesthetic. In conclusion, steel frame formwork is a versatile construction technique, but it does have limitations in terms of shape, size and weight, height and depth, and aesthetic design. These limitations should be carefully considered during the design phase to ensure the practicality and feasibility of using steel frame formwork for a specific structure.

- Q: How does steel frame formwork help in achieving a high-quality concrete finish?

- Steel frame formwork helps in achieving a high-quality concrete finish by providing a stable and rigid structure for pouring and shaping the concrete. The steel frames are designed to be extremely durable and can withstand the pressure exerted by the wet concrete. This ensures that the formwork maintains its shape and does not deform or collapse during the pouring process, resulting in a smooth and even concrete surface. Additionally, steel frame formwork allows for precise and accurate placement of the concrete. The frames are typically adjustable, allowing for easy customization to fit different project requirements. This level of flexibility ensures that the concrete is poured exactly where it needs to be, reducing the risk of any imperfections or inconsistencies. Moreover, steel frame formwork provides excellent support for reinforcing materials such as rebar. The rigid structure of the steel frames holds the reinforcing materials in place, preventing them from shifting or sinking during the pouring process. This ensures that the concrete is properly reinforced, resulting in a stronger and more durable finished product. Furthermore, steel frame formwork allows for efficient and consistent concrete curing. The frames are often designed with built-in channels or holes for the insertion of curing agents such as water or chemicals. This enables the concrete to cure evenly and thoroughly, enhancing its strength and durability. In summary, steel frame formwork plays a crucial role in achieving a high-quality concrete finish by providing stability, precision, and support during the pouring and shaping process. Its durability, adjustability, and ability to facilitate efficient curing contribute to the overall quality and longevity of the concrete structure.

- Q: Can steel frame formwork be used in marine or coastal construction?

- Yes, steel frame formwork can be used in marine or coastal construction. Steel is a durable and corrosion-resistant material that can withstand the harsh conditions present in marine environments. It provides the necessary strength and stability for concrete structures in coastal areas, making it a suitable choice for formwork.

- Q: What are the different types of formwork ties used in steel frame formwork?

- In steel frame formwork, various types of formwork ties are utilized, each possessing distinct characteristics and benefits. Some commonly employed forms include: 1. Snap Ties: These formwork ties are the most fundamental and widely used. They consist of two flat plates with a threaded rod positioned in between. Snap ties offer effortless usage and establish secure connections between formwork panels. 2. Wedge Ties: This tie variant entails a flat plate inserted into a slot on the formwork panel. A wedge is then driven into the slot to secure the tie in place. Wedge ties are characterized by their swift and simple installation process, while still providing robust connections. 3. Coil Ties: Constructed from a continuous loop of wire threaded through the formwork panels, coil ties are secured by twisting the ends together. Their versatility enables application across a wide range of formwork scenarios. 4. She-Bolts: In situations where external ties are impractical, she-bolts are employed. They consist of a threaded rod inserted into a hole drilled through the formwork panel, with a washer and nut used to ensure the tie remains secure. 5. Cone Ties: Cone ties possess a conical shape on one end, similar to snap ties. This design facilitates easy removal of the tie after the concrete has cured. Cone ties find frequent use in scenarios where prompt formwork removal is necessary. 6. Flat Ties: Flat ties are fashioned from flat steel bars inserted through the formwork panels. Their fixation is achieved by utilizing nuts and washers on both sides of the formwork. Flat ties deliver a sturdy and reliable connection. 7. Z Ties: Z ties derive their name from their Z-shaped profile. Inserted into the formwork panels and secured with nuts and washers, Z ties are commonly employed in applications requiring high load capacity and stability. These examples represent merely a selection of the diverse range of formwork ties employed in steel frame formwork. The choice of tie depends on project-specific criteria, including the type of formwork utilized, desired load capacity, and ease of installation and removal.

- Q: What are the different types of safety features incorporated in steel frame formwork systems?

- Steel frame formwork systems commonly include various safety features to ensure worker protection and prevent accidents on construction sites. Some of the frequently seen safety features are as follows: 1. Guardrails: Guardrails are installed along the edges of the formwork to act as a physical barrier, preventing workers from falling. 2. Toe boards: At the bottom of the formwork, toe boards are installed to prevent any tools, materials, or debris from falling and potentially causing harm to workers below. 3. Safety nets: In conjunction with steel frame formwork systems, safety nets provide an additional layer of protection against falls. These nets are usually placed below the formwork to catch workers or objects in case of a fall. 4. Access platforms and ladders: Access platforms and ladders are included in steel frame formwork systems to ensure safe and easy access to the formwork. These platforms and ladders are designed to be sturdy and secure, facilitating workers to move up and down the formwork with safety. 5. Fall arrest systems: Individual protection against falls is provided by fall arrest systems, such as harnesses and safety lines, which are often used alongside steel frame formwork systems. These systems are designed to stop a fall and prevent a worker from hitting the ground. 6. Warning signs and labels: Safety on steel frame formwork systems is enhanced by incorporating warning signs and labels. These signs and labels provide vital information regarding potential hazards, safety precautions, and instructions for proper usage. Overall, the integration of these safety features in steel frame formwork systems creates a safe working environment, reduces the risk of accidents, and safeguards the well-being of workers on construction sites.

- Q: How does steel frame formwork handle different types of formwork curing techniques?

- Steel frame formwork is a versatile and durable system that can effectively handle different types of formwork curing techniques. The steel frame provides excellent support and stability, allowing for various curing methods to be implemented. One common technique is the traditional wet curing method, where the formwork is kept damp with water to facilitate proper hydration of the concrete. Steel frame formwork is designed to withstand the moisture and pressure associated with wet curing. The steel frames are typically coated with anti-corrosion materials, ensuring their longevity and resilience against water exposure. Another technique is the use of curing compounds or membranes, which are applied to the formwork surface to create a barrier that retains moisture and promotes proper curing. The smooth surface of the steel frame formwork allows for easy application and adherence of these compounds. The steel frames also provide a solid base for the curing compounds to bond with, ensuring a strong and effective curing process. Additionally, steel frame formwork can accommodate the use of insulating materials for curing, such as thermal blankets or foam boards. These materials are placed on the formwork surface to retain heat and promote a controlled curing environment, especially in colder climates. The steel frame formwork provides a sturdy structure to support the weight of the insulating materials and ensures proper insulation throughout the curing process. Overall, steel frame formwork is well-suited to handle different types of formwork curing techniques. Its strength, durability, and resistance to moisture make it a reliable choice for various curing methods. Whether it is wet curing, curing compounds, or insulation, the steel frame formwork system can effectively support and facilitate the curing process, resulting in high-quality and durable concrete structures.

Send your message to us

Tabel Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords