Custom High Security H20 Timber Beam Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

pouring straight wall

Concrete Wall Formwork

Waterproof Wall Formwork

retaining wall formwork

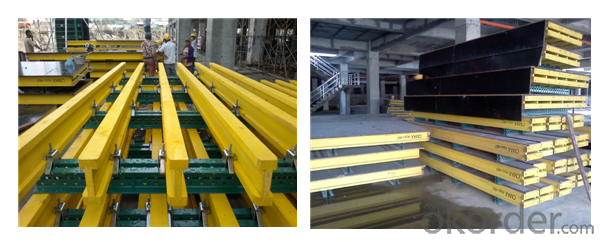

Custom High Security H20 Timber Beam Formwork for Straight Concrete Wall

Description:

1. Structure sketch

TBW system-A is a kind of formwork for pouring straight wall, it is composed of several pieces of Tim-formwork, yoke, tie rod, wing nut, etc.

It will be designed according to wall’s size.

Competitive Advantage:

1. Prefabricated connection, convenient and efficient.

2. Light weight but high bearing capacity.

For conventional design, its load bearing capacity is 60KN/m2 with weight of 55-60kg/m2.

If required, the formwork can be specially designed for higher concrete pressures.

3. Timber is easy resized, so the Tim-formwork is relatively easier to change self’s size and shape. This approved formwork’s economical efficiency.

Applications:

- Q: What are the different types of connections used with steel frame formwork?

- There are several types of connections used with steel frame formwork, each serving a specific purpose and offering different advantages. Some of the most commonly used connections include: 1. Wedge connections: These are simple and quick connections that involve inserting a wedge into a slot to secure the formwork panels together. They provide good stability and are easy to assemble and disassemble. 2. Pin and wedge connections: This type of connection involves inserting a pin into a hole in the formwork panel and securing it with a wedge. It provides a strong connection and is commonly used for larger formwork systems. 3. Bolted connections: Bolted connections involve using bolts and nuts to connect the formwork panels together. This type of connection offers excellent stability and strength, making it suitable for heavy-duty applications. 4. Clip-on connections: Clip-on connections use spring-loaded clips to connect the formwork panels. They are quick and easy to use, allowing for fast assembly and disassembly of the formwork system. 5. Hinged connections: Hinged connections involve using hinges to connect the formwork panels. This type of connection allows for flexibility and adjustability, making it suitable for curved or irregularly shaped structures. 6. Magnetic connections: Magnetic connections use magnets to hold the formwork panels together. This type of connection is convenient and eliminates the need for additional tools or hardware. Overall, the choice of connection type depends on factors such as the size and complexity of the formwork system, the required strength and stability, and the ease of assembly and disassembly.

- Q: Can steel frame formwork be used for foundations?

- Foundations can indeed utilize steel frame formwork. This particular system is known for its versatility and durability, as it can easily adapt to various foundation shapes and sizes. By providing a solid and sturdy framework, it enables the precise and accurate construction of foundation structures through the pouring of concrete. Steel frame formwork proves especially valuable in larger construction projects, where efficiency, strength, and speed are crucial considerations. Moreover, its reusability makes it a cost-effective choice for foundation construction. Nonetheless, it is vital to ensure that the steel frame formwork is expertly designed and installed to withstand the pressures and loads exerted during the concrete pouring process.

- Q: How does steel frame formwork prevent concrete segregation or bleeding?

- Steel frame formwork prevents concrete segregation or bleeding by providing a rigid and stable structure that holds the concrete in place during the pouring and curing process. When concrete is poured into the steel frame formwork, it is contained within the framework, preventing the mixture from spreading or separating. The steel frame acts as a barrier, ensuring that the concrete remains in place and does not segregate or bleed. The steel frame formwork also helps in maintaining the correct consistency and workability of the concrete. It provides a smooth and even surface against which the concrete can be compacted, reducing the chances of air pockets or voids. This compacting action helps to prevent bleeding, which occurs when water rises to the top of the concrete surface and causes the cement and aggregate to separate. Additionally, the steel frame formwork provides support and stability to the concrete structure as it cures. This prevents any movement or displacement of the concrete, which can lead to segregation or bleeding. The rigid nature of the steel frame ensures that the concrete maintains its desired shape and form, resulting in a strong and durable final product. In conclusion, steel frame formwork is an effective solution for preventing concrete segregation or bleeding. Its rigid and stable structure contains the concrete, maintains its consistency, and provides support during the curing process, resulting in a high-quality and homogeneous finished concrete structure.

- Q: How does steel frame formwork affect the overall weight of a construction project?

- The overall weight of a construction project can be significantly affected by the use of steel frame formwork. In comparison to traditional timber formwork, steel frame formwork generally weighs much less. This decrease in weight brings about a number of advantages. Firstly, it simplifies the transportation and handling of the formwork, making it more efficient. The steel frame formwork can be easily taken apart, transported, and put back together at different locations. This is particularly beneficial for large-scale construction projects that require frequent repositioning of the formwork. Secondly, the lighter weight of the steel frame formwork enables a faster and more streamlined construction process. Construction workers can easily lift and move the lighter formwork, allowing for quicker installation and removal. This efficiency leads to shorter construction times and lower labor costs. Furthermore, the reduced weight of the steel frame formwork positively impacts the load-bearing capacity of the overall structure. By decreasing the weight of the formwork, more of the load-bearing capacity can be allocated to the actual building materials, such as concrete or steel beams. As a result, the construction becomes sturdier and more efficient, with enhanced durability and safety. In conclusion, the use of steel frame formwork significantly reduces the weight of a construction project, resulting in easier transportation, faster construction, and improved load-bearing capacity. Its lightweight nature contributes to the overall efficiency, cost-effectiveness, and quality of the construction process.

- Q: Can steel frame formwork be easily integrated with prefabricated building components?

- Yes, steel frame formwork can be easily integrated with prefabricated building components. Steel frame formwork provides a sturdy and durable structure for the construction process, making it compatible with various prefabricated components. The flexibility and versatility of steel frame formwork allow it to be easily adapted to the dimensions and specifications of prefabricated building components. Additionally, steel frame formwork can be easily adjusted and modified to accommodate changes in design or construction requirements. This integration of steel frame formwork with prefabricated building components helps streamline the construction process, reduce labor costs, and enhance overall project efficiency.

- Q: How does steel frame formwork ensure proper consolidation of concrete during pouring?

- Steel frame formwork ensures proper consolidation of concrete during pouring by providing a rigid and stable structure that holds the concrete in place until it solidifies. The steel frame acts as a mold or template, allowing the concrete to be poured and shaped according to the desired design. One of the key advantages of steel frame formwork is its ability to resist the pressure exerted by the weight of the concrete. The frame is constructed using strong steel beams and columns that can withstand the forces generated during the pouring process. This ensures that the formwork does not deform or collapse under the weight of the concrete, resulting in a consistent and uniform placement of the material. Additionally, steel frame formwork often includes adjustable features such as clamps, braces, and tie rods. These components allow the formwork to be securely fastened and tightened, preventing any movement or displacement of the concrete during pouring. This helps in achieving proper consolidation of the concrete, as it ensures that the material remains in its intended position without any voids or gaps. Furthermore, the steel frame formwork system can be designed to include various reinforcement mechanisms. This includes the use of steel bars or mesh within the formwork, which provides additional strength and stability to the structure. This reinforcement helps in preventing any potential cracking or deformation of the concrete, ensuring that it remains properly consolidated. Overall, the use of steel frame formwork provides a reliable and efficient method for ensuring proper consolidation of concrete during pouring. The robustness and stability of the steel frame, coupled with adjustable features and reinforcement mechanisms, allow for a controlled and uniform placement of the material, resulting in a high-quality finished product.

- Q: What are the different types of formwork connections used with steel frame formwork?

- Steel frame formwork can be used with several different types of connections to securely join the formwork panels together during the concrete pouring process. Some commonly used connections include the following: 1. Wedge connections: Steel wedges are inserted into pre-drilled holes in the formwork panels and tightened to hold the panels securely. 2. Bolted connections: Bolts, nuts, and washers are used to join the formwork panels. Holes are drilled in the panels and bolts are inserted through them, with nuts and washers tightened to secure the panels. 3. Pin and wedges connections: Steel pins are inserted into holes in the formwork panels, and wedges are driven into slots on the pins to hold the panels together. 4. Clamping connections: Clamps or clamping devices are used to join the formwork panels. These clamps are tightened around the panels, applying pressure for a secure connection. 5. Magnetic connections: Magnets embedded within the formwork panels create a strong bond between them, eliminating the need for additional connectors. 6. Hook and loop connections: Straps with hook and loop fasteners are used to join the formwork panels. These straps are wrapped around the panels, providing a secure connection. The choice of formwork connection depends on factors such as project requirements, the formwork system being used, and the desired level of ease and speed of assembly. Each type of connection has its own advantages and disadvantages.

- Q: Are there any specific design considerations for steel frame formwork?

- Yes, there are several specific design considerations for steel frame formwork. Firstly, the structural integrity and stability of the steel frame need to be ensured to withstand the loads and pressures during concrete pouring. The design should also take into account the required formwork strength, rigidity, and dimensional accuracy. It is important to consider the arrangement and spacing of the steel frames to provide adequate support and prevent deflection or deformation. Additionally, the design should allow for easy assembly, disassembly, and reusability of the steel frames, ensuring efficient and cost-effective construction processes. Proper consideration should also be given to the formwork's compatibility with other construction materials and integration with the overall structural design.

- Q: How does steel frame formwork facilitate the construction of walls and columns?

- There are several ways in which steel frame formwork aids in the construction of walls and columns. Firstly, its high durability allows it to withstand the pressure exerted by wet concrete, enabling the creation of sturdy structures capable of supporting heavy loads. Secondly, the customizable nature of steel frame formwork allows for easy adjustment to different shapes and sizes. This adaptability facilitates the construction of walls and columns with intricate designs and varying dimensions. The formwork can be quickly assembled and disassembled, leading to efficient and cost-effective construction. Furthermore, steel frame formwork ensures excellent stability and alignment, guaranteeing accurate construction according to desired specifications. This precision is crucial for maintaining structural integrity and achieving a top-quality finish. Moreover, steel frame formwork's reusability makes it an environmentally friendly option for construction projects. After each use, the formwork can be cleaned, repaired, and stored for future use, reducing waste generation and minimizing expenses. To summarize, steel frame formwork is a valuable asset in the construction of walls and columns. Its durability, flexibility, stability, and reusability all contribute to an efficient and effective construction process, resulting in strong and well-constructed structures.

- Q: Can steel frame formwork be used in combination with post-tensioning techniques?

- Yes, steel frame formwork can be used in combination with post-tensioning techniques. The steel frame formwork provides a sturdy structure to support the post-tensioned cables and helps in achieving the desired shape and dimensions of the concrete structure being constructed.

Send your message to us

Custom High Security H20 Timber Beam Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches