Steel Fram Formworks Used for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork GK120 Description

There is a prizing part designed in the corner, which can help to position and remove formwork easily.The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork GK120

-convenient for construction

-easy to control the quality

-easy, rapid and economical.

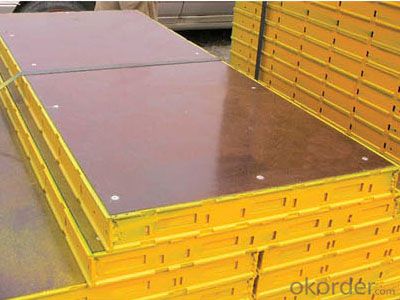

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120Specifications

Steel Frame Formwork GK120 is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

5.Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the Steel Frame Formwork GK120 and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: What is the role of steel frame formwork in achieving a smooth concrete finish?

- The role of steel frame formwork in achieving a smooth concrete finish is crucial. Steel frame formwork is used to create a temporary mold or structure that holds the concrete in place while it cures and hardens. It provides support and stability to the wet concrete, preventing any deformation or cracks that may occur during the curing process. One of the main benefits of using steel frame formwork is its ability to provide a precise and accurate shape to the concrete. The steel frames are designed to be rigid and sturdy, ensuring that the concrete maintains its desired shape and dimensions. This is particularly important when constructing structures with complex designs or intricate details. Additionally, steel frame formwork helps to achieve a smooth concrete finish by minimizing surface imperfections. The rigid structure of the steel frames prevents any movement or shifting of the concrete, resulting in a consistent and even surface. This is especially important when the concrete surface needs to be visually appealing or when a smooth finish is required for functional purposes, such as in flooring or walls. Furthermore, steel frame formwork allows for easy removal and reuse. Once the concrete has cured and hardened, the formwork can be dismantled and removed, leaving behind a clean and finished concrete surface. The steel frames can then be cleaned and reused for future projects, reducing construction costs and minimizing waste. In conclusion, the role of steel frame formwork in achieving a smooth concrete finish is indispensable. It provides the necessary support and stability to ensure the concrete maintains its desired shape and dimensions, while also minimizing surface imperfections. By using steel frame formwork, construction projects can achieve high-quality and visually appealing concrete finishes.

- Q: How long does steel frame formwork last?

- The lifespan of steel frame formwork can vary depending on factors such as maintenance, usage, and quality of the materials. However, with proper care and regular maintenance, steel frame formwork can last for several years, making it a durable and long-lasting choice for construction projects.

- Q: How does steel frame formwork help in reducing construction errors?

- The use of steel frame formwork in construction involves employing steel frames as a supportive structure for pouring concrete. This technique offers numerous advantages compared to traditional formwork systems, particularly in terms of reducing construction errors. To begin with, steel frame formwork guarantees a high level of accuracy and precision. The frames are manufactured with strict adherence to specifications, ensuring perfect alignment and levelness. This eliminates the risk of misalignment or unevenness in the concrete structure. By providing a robust and stable template for concrete pouring, steel frame formwork minimizes the occurrence of errors such as uneven surfaces, crooked walls, or out-of-plumb columns. Moreover, steel frame formwork provides a great degree of flexibility and adaptability. The frames can be easily adjusted and reconfigured to accommodate changes in design or layout. This allows for increased flexibility during the construction process, reducing the likelihood of errors resulting from design modifications or unforeseen circumstances. Additionally, the steel frames can be reused multiple times, reducing the need for new formwork materials and minimizing the chances of errors caused by poor-quality or ill-fitting formwork. Another important factor in reducing construction errors is the efficient and time-saving installation process of steel frame formwork. The frames are typically pre-fabricated off-site and delivered to the construction site, ready for immediate use. This eliminates the need for on-site fabrication and reduces the chances of errors caused by human error or inconsistencies in construction methods. The quick and efficient installation process also reduces the overall construction time, minimizing the chances of errors due to rushed or hasty work. Furthermore, steel frame formwork provides better control over the concrete pouring process. The frames are equipped with built-in features such as tie rods, adjustable struts, and alignment systems, ensuring even and consistent pouring of concrete. This eliminates the risk of errors such as honeycombing, voids, or weak spots in the concrete structure. By providing a controlled and regulated environment for concrete pouring, steel frame formwork helps achieve high-quality and error-free construction. In conclusion, steel frame formwork plays a vital role in reducing construction errors by offering accuracy, flexibility, efficiency, and control in the construction process. By utilizing steel frames as a supportive structure for concrete pouring, this method ensures precise alignment, minimizes errors caused by design changes, provides efficient installation, and enables control over the concrete pouring process. These advantages make steel frame formwork an effective solution for reducing construction errors and achieving high-quality, error-free constructions.

- Q: How does steel frame formwork affect the overall aesthetics of a concrete structure?

- Steel frame formwork does not directly affect the overall aesthetics of a concrete structure as it is typically hidden within the final finishes. Its primary role is to provide support and shape to the concrete during construction. However, the precision and quality of steel frame formwork can indirectly contribute to the overall aesthetics by ensuring a smooth and accurately formed concrete surface, which can enhance the appearance of the structure once the finishes are applied.

- Q: Can steel frame formwork be used for both single-sided and double-sided concrete pouring?

- Yes, steel frame formwork can be used for both single-sided and double-sided concrete pouring. Steel frame formwork is versatile and can be easily adjusted and assembled to accommodate different pouring requirements. For single-sided concrete pouring, the formwork is positioned on one side of the structure, while for double-sided pouring, the formwork is positioned on both sides. The steel frame formwork provides the necessary support and stability to contain the concrete and ensure it sets properly. Additionally, steel frame formwork is durable and can withstand the pressure exerted by the concrete, making it suitable for both types of pouring.

- Q: How does steel frame formwork prevent the formation of concrete bleeding or excess water accumulation?

- Steel frame formwork prevents the formation of concrete bleeding or excess water accumulation by providing a strong and rigid structure that holds the concrete in place during the pouring and curing process. The steel frame formwork acts as a barrier, preventing the flow of excess water or bleeding of the concrete mixture, ensuring a consistent and uniform distribution of materials. Additionally, the tight joints and connections in the steel frame formwork further minimize the risk of water seepage or leakage, resulting in a high-quality and durable concrete structure.

- Q: Can steel frame formwork be used for both straight and curved staircase construction?

- Indeed, the utilization of steel frame formwork is applicable for the construction of both straight and curved staircases. This adaptable and pliable solution allows for effortless adjustments to accommodate diverse shapes and designs. By providing the essential support and structure during the construction phase, it enables the creation of both straight and curved staircases. The steel frame formwork system can be tailored and molded to mirror the desired curvature of the staircase, guaranteeing meticulous and precise construction. Moreover, steel frame formwork ensures durability and robustness, rendering it suitable for a myriad of construction projects, including staircase construction.

- Q: Is steel frame formwork suitable for the construction of bridges?

- Yes, steel frame formwork is suitable for the construction of bridges. Steel offers high strength and durability, making it capable of withstanding the heavy loads and forces exerted by bridge structures. Steel frame formwork also allows for easy customization and adjustment, making it an ideal choice for complex bridge designs. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for bridge construction projects.

- Q: How does steel frame formwork contribute to the overall energy efficiency of a building?

- The use of a steel frame in construction, known as steel frame formwork, is a technique that involves temporary molds to shape concrete structures. This method offers various benefits for a building's energy efficiency. To begin with, steel frame formwork allows for the creation of precise, durable, and strong concrete structures. The steel frames ensure accurate alignment and adjustments, resulting in airtight and well-insulated building elements. This precision minimizes energy loss from air leakage and heat transfer, thus enhancing the overall energy efficiency of the building. Furthermore, steel frame formwork enables the incorporation of high-performance insulation materials. The formwork can accommodate thicker insulation layers, significantly improving the thermal performance of the building envelope. This enhanced insulation reduces heat transfer between the interior and exterior, leading to decreased energy consumption for heating and cooling. Additionally, steel frame formwork facilitates the integration of various energy-efficient building systems. Channels or conduits for electrical wiring, plumbing, and HVAC systems can be incorporated into the formwork. By integrating these systems during construction, the overall energy efficiency of the building can be optimized. For instance, the inclusion of energy-efficient lighting fixtures or smart thermostats further reduces energy consumption and enhances occupant comfort. Moreover, steel frame formwork provides flexibility for future modifications or renovations. The adjustable nature of the formwork allows for easy incorporation of changes or upgrades to the building's energy-efficient systems. This adaptability ensures that the building remains up-to-date with evolving energy efficiency standards and technologies, maximizing long-term sustainability. In conclusion, steel frame formwork contributes to a building's energy efficiency by providing precise alignment for well-insulated structures, enabling the use of high-performance insulation materials, facilitating the integration of energy-efficient building systems, and allowing for future modifications. By utilizing steel frame formwork in construction, buildings can achieve higher energy efficiency, resulting in reduced energy consumption, lower carbon emissions, and improved sustainability.

- Q: How does steel frame formwork accommodate for openings and recesses in the concrete structure?

- When it comes to accommodating openings and recesses, steel frame formwork is a highly versatile and efficient method for constructing concrete structures. By utilizing removable panels, the formwork system can easily be customized to incorporate windows, doors, and other necessary openings in the design. To accommodate these openings, the steel frame formwork system is specifically designed with detachable panels. These panels can be effortlessly detached and repositioned in order to create the desired openings within the concrete structure. Standardized panel sizes further enhance the ease of interchangeability and flexibility during the construction process. Furthermore, steel frame formwork excels at accommodating recesses within the concrete structure. By utilizing specially designed panel inserts, recesses such as niches or beam pockets can be created within the formwork. These inserts are strategically placed within the formwork panels to achieve the desired recess shape and dimensions. The steel frame formwork system ensures precise placement of these inserts, resulting in accurate and consistent recesses within the concrete structure. The utilization of steel frame formwork for accommodating openings and recesses offers numerous advantages in the construction process. The system can be easily adjusted and adapted to meet the specific requirements of the design, enabling efficient construction of complex concrete structures. Overall, steel frame formwork provides a practical solution for accommodating openings and recesses in concrete structures. Its versatility, accuracy, and flexibility make it an ideal choice for construction projects where precision and customization are crucial factors.

Send your message to us

Steel Fram Formworks Used for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords