Formwork Parts Scaffolding System Formwork System Parts

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Formwork Parts Scaffolding System Formwork System Parts

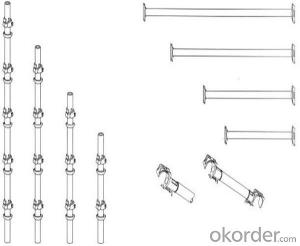

Product pictures:

Product description:

Name: | RingLock Scaffold System |

Category: | Scaffolding System |

Material: | Steel (Q235/Q345) |

Size: | D48*3.25mm, etc |

Surface: | Electro Galvanized, Hot Dipped Galvanized, Painted, Powder Coated |

Component: | Standard, Ledger, Diagonal Brace, Bracket, Base Jack, U Head Jack, Etc. |

Application: | Slab Support, Staircase, Stage Plateforms, Bridge Support, Mobile Tower, etc. |

Manufacturer: | OEM is Available |

Items or goods can be manufactured according to your standards. | |

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Excellent quality for formwork & scaffolding with wide choices

Other scaffolding & formwork products:

(1) Scaffolding System:

(2) Scaffolding Frame & Accessories:

(3) Scaffolding Couplers/Clamps:

(4) Formwork System Scaffolding & Accessories:

Company introduce and advantages:

1. A state-owned company, prestige fi rst.

2. One of Fortune 500 companies in the world. No. 5 in the building material fi eld.

3. Six Sigma strategy , which means no more than 3.4 defects existing among one million of error

possibilities.

4. In line with the business, we launched E-business platform Okorder.com.

5. We are highly recognized by our business partners and clients all over the world and has obtained rapid

development under the spirit of win-win.

FAQ

Why Us?

We are one of the largest construction materials suppliers in China.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: What are the different types of connection details used with steel frame formwork?

- There are several different types of connection details that can be used with steel frame formwork in construction projects. These connection details are crucial for ensuring stability and strength in the formwork system. Some of the commonly used connection details include: 1. Wedge connections: This type of connection involves using wedge-shaped connectors that are inserted into pre-drilled holes in the steel frames. The wedges are then tightened to secure the frames together, creating a strong and stable connection. 2. Pin connections: Pin connections involve using steel pins or bolts to connect the steel frames together. The pins are inserted through pre-drilled holes in the frames and secured with nuts or other fasteners. This type of connection provides a strong and rigid joint between the frames. 3. Clamp connections: Clamp connections are achieved by using specially designed clamps that grip the steel frames together. The clamps are tightened using bolts or other fasteners, creating a secure connection between the frames. This type of connection is commonly used in situations where quick assembly and disassembly of the formwork is required. 4. Welded connections: Welded connections involve permanently joining the steel frames together using welding techniques. This type of connection provides maximum strength and stability but requires skilled welders and additional time for fabrication and installation. 5. Hybrid connections: Hybrid connections combine different types of connection details to achieve the desired level of strength and stability. For example, wedge connections can be used in combination with pin connections to enhance the overall rigidity of the formwork system. The choice of connection details will depend on various factors such as the specific project requirements, the load conditions, the desired level of formwork reusability, and the available equipment and resources. It is essential to consult with structural engineers and formwork specialists to determine the most suitable connection details for a particular steel frame formwork system.

- Q: Does steel frame formwork require any specific vibration techniques for concrete compaction?

- Concrete compaction when using steel frame formwork necessitates the application of specific vibration techniques. Steel frame formwork is a construction system that supports newly poured concrete and guarantees its desired shape. In order to eliminate air voids and promote adequate bonding between the concrete and reinforcement, the concrete within the formwork must be compacted. Vibration serves as a crucial compaction method. By removing trapped air bubbles, vibration prevents concrete weakness and reduces the risk of decreased strength. Additionally, vibration facilitates the even distribution and consistent density of the concrete in all corners and tight spaces of the formwork. For effective compaction with steel frame formwork, it is advisable to employ either internal vibrators or external vibrators. Internal vibrators, also referred to as immersion or poker vibrators, are vertically inserted into the concrete at regular intervals. These vibrators generate high-frequency vibrations that consolidate the concrete. On the other hand, external vibrators are affixed to the formwork itself. They produce vibrations that are transmitted to the concrete via the formwork. External vibrators are commonly used for larger areas or when a uniform vibration is necessary. The specific techniques for concrete compaction with steel frame formwork are contingent upon variables such as the concrete mix design, formwork dimensions, and desired finish. Adhering to the manufacturer's guidelines and employing best practices for vibration techniques is essential. In conclusion, specific vibration techniques are required for concrete compaction when using steel frame formwork. These techniques involve the utilization of internal or external vibrators to ensure proper consolidation and eliminate air voids within the freshly poured concrete. By following recommended practices and guidelines, a durable and high-quality concrete structure can be achieved.

- Q: How does steel frame formwork ensure accurate dimensions and alignment?

- Accurate dimensions and alignment are ensured by the rigid and sturdy structure of steel frame formwork. Precision-designed and manufactured steel frames guarantee perfect straightness and correct dimensions, enabling the creation of uniformly sized and aligned concrete structures. To provide stability and support during concrete pouring, the steel frames are assembled together to form a robust framework. They are securely fixed in place, preventing any movement or shifting during the concrete casting process. This eliminates the risk of dimensional variations or misalignments in the final structure. Furthermore, the steel formwork system allows for precise adjustment and leveling. Adjustable props, wedges, and clamps are integrated into the frames, enabling fine-tuning of the formwork's position and alignment. This allows the construction team to achieve accurate dimensions and alignment according to project specifications. The steel panels used in the formwork system contribute to dimensional accuracy by providing a smooth and seamless surface finish. Constructed with high-quality materials, these panels prevent warping or bending, resulting in a consistent and even surface. This eliminates the need for excessive plastering or finishing work, further enhancing the accuracy of dimensions and alignment. Overall, the utilization of steel frame formwork in construction projects guarantees accurate dimensions and alignment. It provides a strong and stable framework, facilitates precise adjustments, and delivers a smooth surface finish. This ensures that the final concrete structures meet required specifications and achieve the desired level of accuracy.

- Q: What are the key considerations for selecting the appropriate steel frame formwork accessories?

- Some key considerations for selecting the appropriate steel frame formwork accessories include the compatibility with the formwork system being used, the desired level of strength and durability, the ease of assembly and disassembly, the ability to accommodate different concrete pouring techniques, the availability of necessary safety features, and the overall cost-effectiveness of the accessories.

- Q: How does steel frame formwork provide support to the concrete structure?

- Steel frame formwork is a construction technique that involves using steel frames to provide support to the concrete structure during the pouring and setting process. The steel frames are designed and engineered to withstand the weight and pressure of the wet concrete, ensuring that the structure maintains its shape and integrity. The steel frames are typically made of strong and durable steel beams, columns, and braces that are interconnected to form a rigid and stable framework. This framework acts as a temporary mold or template that holds the liquid concrete in place until it hardens and gains strength. One of the key advantages of steel frame formwork is its ability to provide support and stability to the concrete structure, even in challenging construction scenarios. The steel frames can be easily adjusted and customized to accommodate different shapes and sizes of structures, making it a versatile solution for various construction projects. During the pouring process, the steel frame formwork is carefully positioned and secured in place. It is then filled with the wet concrete mixture, which flows and fills all the voids within the frame. The steel frames prevent the concrete from spreading or deforming under its weight, ensuring that it maintains the desired shape and dimensions. As the concrete sets and hardens, the steel frames continue to provide support and prevent any movement or deformation. This is crucial in ensuring that the structure achieves the desired strength and durability. Once the concrete has fully cured, the steel frame formwork can be removed, leaving behind a solid and well-supported concrete structure. In summary, steel frame formwork plays a vital role in providing support to the concrete structure during the pouring and setting process. It ensures that the concrete maintains its shape and integrity, ultimately contributing to the strength and durability of the finished structure.

- Q: Can steel frame formwork be used in retrofitting and renovation projects?

- Yes, steel frame formwork can be used in retrofitting and renovation projects. Steel frame formwork is a versatile and durable system that can be easily adapted to fit various project requirements. It provides a strong and stable structure that can withstand the pressures and loads associated with retrofitting and renovation work. Steel frame formwork offers several advantages in retrofitting and renovation projects. Firstly, it is highly customizable, allowing for precise adjustments and modifications to fit existing structures. This makes it suitable for projects that require alterations to accommodate new elements or changes in design. Additionally, steel frame formwork can be reused multiple times, making it a cost-effective solution for retrofitting and renovation projects. Its durability and resistance to wear and tear ensure that it can withstand the rigors of a construction site and be used on multiple projects, reducing the need for frequent replacements. Furthermore, steel frame formwork can be easily assembled and disassembled, providing a time-efficient solution for retrofitting and renovation projects. This is particularly beneficial when working on tight schedules or in occupied buildings, as it minimizes disruption and allows for quicker project completion. In conclusion, steel frame formwork is a suitable choice for retrofitting and renovation projects. Its versatility, durability, and cost-effectiveness make it an ideal solution for adapting existing structures and accommodating changes in design.

- Q: How does steel frame formwork prevent the formation of concrete shrinkage cracks?

- Steel frame formwork prevents the formation of concrete shrinkage cracks by providing strong and rigid support to the concrete during the curing process. It ensures that the concrete remains in its desired shape and position, preventing any movement or displacement that could lead to crack formation. Additionally, the steel frame formwork helps in evenly distributing the forces and stresses exerted by the curing concrete, minimizing the potential for shrinkage cracks to develop.

- Q: How does steel frame formwork contribute to the overall strength and stability of a concrete structure?

- Various ways exist in which steel frame formwork is instrumental in enhancing the overall strength and stability of a concrete structure. Firstly, the steel frame functions as a rigid and robust framework, offering support to the concrete during the pouring and curing process. This containment and shaping of the concrete guarantee the prevention of any sagging, bulging, or deformation that could potentially weaken the structure. In addition, the steel frame formwork allows for precise and accurate placement of the concrete, ensuring consistency and uniformity throughout the structure. This eradicates any potential weak points or irregularities that might compromise the overall strength. Furthermore, the steel frame formwork exhibits excellent resistance against external forces like wind, seismic activity, or heavy loads. Its high tensile strength and durability enable it to withstand these forces, thus enhancing the overall stability of the concrete structure. Moreover, the steel frame formwork creates a controlled environment that facilitates the proper curing of the concrete. This controlled environment minimizes the risk of shrinkage, cracking, or moisture-related issues that could considerably weaken the structure over time. The steel frame formwork's ability to allow for a consistent and controlled curing process contributes to the long-term strength and durability of the concrete structure. In summary, steel frame formwork's contribution to the overall strength and stability of a concrete structure lies in its provision of a rigid support system, ensuring accuracy and uniformity in placement, resisting external forces, and facilitating proper curing. Its durability and robustness make it an indispensable component in the construction process, ultimately enhancing the structural integrity and longevity of the concrete structure.

- Q: How does steel frame formwork contribute to better formwork stability in seismic zones?

- Steel frame formwork contributes to better formwork stability in seismic zones in several ways. Firstly, steel frame formwork is made of high-strength steel, which provides a strong and durable structure. This strength is crucial in seismic zones where the ground experiences high levels of shaking and lateral forces. Unlike other materials like wood or aluminum, steel is able to withstand these forces and maintain its structural integrity. Secondly, steel frame formwork is designed with specific features to enhance stability in seismic zones. It often includes additional bracing and reinforcement elements that help distribute the seismic forces evenly throughout the formwork system. These reinforcements prevent the formwork from collapsing or deforming during an earthquake and ensure that it can safely support the weight of the concrete being poured. Furthermore, steel frame formwork is highly adjustable and customizable. This allows it to be tailored to the specific requirements of a seismic zone. The formwork can be easily modified to accommodate different shapes and sizes of concrete structures, which is important in earthquake-prone areas where buildings may have irregular designs to withstand seismic forces. Additionally, steel frame formwork is reusable, which makes it a cost-effective solution in seismic zones. After each use, the formwork can be disassembled, inspected, and reassembled for the next project. This reduces the need for constant replacement and minimizes waste, making it an environmentally-friendly option as well. Overall, steel frame formwork provides superior stability in seismic zones due to its high-strength construction, additional reinforcements, adjustability, and reusability. Its ability to withstand the forces generated by earthquakes ensures the safety and integrity of the concrete structures being constructed in these areas.

- Q: How does steel frame formwork contribute to the overall speed of construction?

- Steel frame formwork contributes to the overall speed of construction by providing a durable and reusable system that allows for efficient and quick assembly and disassembly of concrete structures. Its lightweight and modular design enables faster installation and dismantling, reducing construction time significantly compared to traditional timber formwork. Additionally, steel frame formwork offers high precision and accuracy, ensuring faster and more accurate concrete pouring, thus accelerating the overall construction process.

Send your message to us

Formwork Parts Scaffolding System Formwork System Parts

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords