Adjustable SF120 System for Rectangle SF120-A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

concrete column formwork

aluminium formwork system

Adjustable SF120 System for Rectangle / Square Concrete Column

Description:

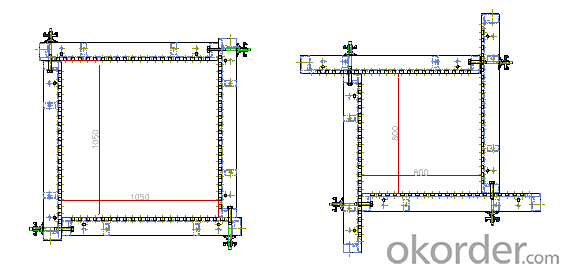

1. Structure sketch

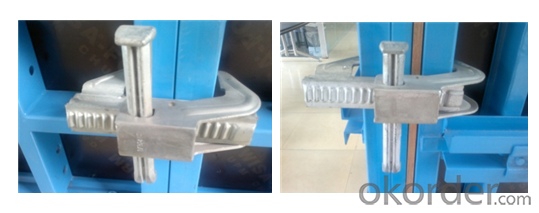

SF120-A is a kind of formwork for pouring rectangle & square column; it is composed of formwork, props, adjustable steel clamp, etc.

Competitive Advantage:

1. High-precision production line guarantees the perfect products.

2. Special hollow steel frame covered with WISA-plywood, light weight but high strength.

Its allowable pressure from fresh concrete is 80KN/m2 with the weight of 65KG/m2.

3. Easy connection with adjustable steel clamp.

4. The system is easy to change the cross section.

Applications:

Applications:

- Q: What are the quality control measures for steel frame formwork removal?

- To ensure the safe and efficient removal of steel frame formwork, quality control measures encompass several steps. Below are some essential measures: 1. Prior to removing the steel frame formwork, a thorough inspection is conducted to detect any damaged or worn-out parts. Any defects or issues discovered during the inspection must be addressed and repaired before proceeding with the removal process. 2. Prior to removal, it is crucial to take appropriate safety precautions. This includes providing workers with the necessary personal protective equipment (PPE) such as safety helmets, gloves, and safety shoes. Clearing the area around the formwork from hazards or obstacles is also essential to prevent accidents during the removal process. 3. The use of suitable tools and equipment is vital for the efficient and safe removal of the formwork. This involves utilizing wrenches, spanners, and tools specifically designed for dismantling steel frame formwork. The correct tools prevent damage to the formwork and ensure a smooth and accurate removal process. 4. The dismantling process should be carried out in a systematic and organized manner. This entails removing the formwork in reverse order of installation, starting from the top and working downwards. It is essential to exercise caution to avoid placing undue stress or pressure on the formwork during removal. 5. Regular inspections should be conducted during the removal process to verify that the formwork is being dismantled correctly. This involves checking for signs of damage, misalignment, or wear and tear. Any identified issues must be promptly addressed to prevent further damage or compromise to the structure. 6. Accurate documentation should be maintained throughout the entire removal process. This includes recording any issues or defects discovered during inspections, as well as documenting the steps taken to address them. Proper documentation helps to track the implemented quality control measures and serves as a reference for future projects. Overall, quality control measures for steel frame formwork removal encompass comprehensive inspections, adherence to safety protocols, the use of proper tools and equipment, methodical dismantling, regular inspections during removal, and accurate documentation. Following these measures ensures the safe and efficient removal of the formwork, minimizing the risk of accidents and preserving the structural integrity of the project.

- Q: What are the considerations for selecting the appropriate formwork for different concrete strengths?

- When selecting the appropriate formwork for different concrete strengths, there are several considerations that need to be taken into account. Firstly, the type and size of formwork should be chosen based on the anticipated concrete strength. Different concrete strengths require different levels of support and reinforcement, so the formwork needs to be able to withstand the pressure exerted by the concrete during pouring and curing. For high-strength concrete, formwork with higher load-bearing capacities and greater rigidity may be necessary. Another consideration is the surface finish required for the final concrete structure. If a smooth and flawless finish is desired, the formwork needs to be able to provide the necessary support and stability to prevent any deformations or surface imperfections. For higher concrete strengths, the formwork should be able to resist the pressure and prevent any bulging or shifting that could result in an uneven surface. The duration of the concrete pouring and curing process is also an important factor. Different concrete strengths have varying curing times, and the formwork needs to be able to withstand the weight of the concrete for the entire duration of the curing process. This includes considering the formwork's ability to resist temperature changes and potential shrinkage or expansion of the concrete as it cures. Additionally, the availability and cost of the formwork should be taken into consideration. Some types of formwork may be more readily available or cost-effective for certain concrete strengths, so it is important to evaluate the practicality and affordability of the formwork options. Lastly, safety is a critical consideration. The formwork should be able to provide a secure and stable environment for workers during the concrete pouring and curing process. It should be able to withstand any potential stresses or pressures without compromising the safety of the construction site. In summary, when selecting the appropriate formwork for different concrete strengths, it is important to consider factors such as load-bearing capacity, surface finish requirements, curing duration, availability, cost, and safety. By carefully evaluating these considerations, a suitable formwork system can be chosen to ensure the successful construction of concrete structures with different strengths.

- Q: Can steel frame formwork be used for both interior and exterior staircase construction?

- Yes, steel frame formwork can be used for both interior and exterior staircase construction. Steel frame formwork is a versatile and durable system that provides excellent support and stability during the construction process. It can be easily customized to fit the specific requirements of staircase construction, regardless of whether it is for an interior or exterior application. The steel frame formwork ensures precise and accurate pouring of concrete, resulting in a high-quality and structurally sound staircase. Additionally, steel frame formwork can be easily disassembled and reused, making it a cost-effective option for both interior and exterior staircase construction projects.

- Q: Can steel frame formwork be used for both horizontal and vertical concrete structures?

- Yes, steel frame formwork can be used for both horizontal and vertical concrete structures. Steel frame formwork is a versatile and durable system that can be easily assembled and disassembled, making it suitable for various construction projects. It provides a strong and rigid support for the concrete during pouring and curing, ensuring proper alignment and stability for both horizontal slabs and vertical walls. Additionally, steel frame formwork allows for precise adjustment and customization to accommodate different shapes and sizes of structures. Its robust construction and ability to withstand high pressure and load make it an ideal choice for both horizontal and vertical concrete structures.

- Q: Can steel frame formwork be used in areas with high wind loads?

- Yes, steel frame formwork can be used in areas with high wind loads. Steel is a strong and durable material that can withstand high wind forces. The rigid construction of steel frame formwork provides stability and resistance against wind pressure. However, it is important to ensure that the formwork is properly anchored and braced to the structure to prevent any displacement or failure due to the wind loads. Additionally, the design and engineering of the formwork system should consider the specific wind load requirements of the area to ensure its suitability and safety.

- Q: How does steel frame formwork prevent the formation of cold joints in the concrete?

- By offering a continuous support system throughout the pouring and curing process, steel frame formwork effectively prevents the formation of cold joints in concrete. Cold joints occur when fresh concrete is poured against hardened or partially hardened concrete, weakening the bond between the two sections. With steel frame formwork, the concrete is securely contained within a rigid structure, leaving no room for movement or displacement during pouring and curing. This eliminates any chance of cold joints forming. Moreover, the steel frame formwork enables proper alignment and positioning of reinforcing bars within the concrete. This ensures that the steel reinforcement is correctly placed and adequately covered with concrete, reducing the risk of cold joints around the reinforcement. Additionally, the steel frame formwork helps maintain the desired shape and dimensions of the concrete structure. Its sturdy and stable framework prevents any deformation or shifting that could result in cold joints. Furthermore, the steel frame formwork promotes uniform distribution of the concrete mix and aids in achieving a consistent surface finish. It allows for controlled pouring and compacting, reducing the likelihood of voids or air pockets that can lead to cold joints. In conclusion, the use of steel frame formwork provides a reliable and robust system for pouring concrete. It ensures proper containment and support, significantly reducing the risk of cold joint formation and resulting in a stronger and more durable concrete structure.

- Q: Can steel frame formwork be used for both vertical and horizontal concrete elements?

- Yes, steel frame formwork can be used for both vertical and horizontal concrete elements. The strength and durability of steel make it suitable for constructing various types of formwork, ensuring stability and accuracy in shaping concrete structures in both vertical and horizontal orientations.

- Q: Can steel frame formwork be used for both temporary and permanent concrete structures?

- Yes, steel frame formwork can be used for both temporary and permanent concrete structures. Its durability and strength make it suitable for long-term use in permanent structures, while its flexibility and ease of assembly and disassembly make it ideal for temporary structures.

- Q: Can steel frame formwork be used for industrial structures?

- Certainly! Industrial structures can indeed utilize steel frame formwork. This system, known for its versatility and durability, offers a multitude of advantages when it comes to constructing such buildings. To begin with, steel frame formwork boasts exceptional strength and rigidity. Consequently, it is well-suited for supporting heavy loads and enduring the typical forces encountered in industrial construction. As a result, it becomes a dependable option for erecting expansive industrial edifices like warehouses, factories, and power plants. Furthermore, steel frame formwork presents an elevated level of customization and flexibility. It can be easily adjusted and modified to accommodate various shapes and sizes, thereby enabling the construction of intricate industrial structures with diverse configurations. This adaptability proves particularly invaluable in industrial environments where unique designs and layouts may be necessary. Moreover, steel frame formwork demonstrates remarkable durability and longevity. It can endure harsh environmental conditions, including extreme temperatures, moisture, and exposure to chemicals. This durability ensures that industrial structures constructed using steel frame formwork will have a prolonged lifespan and require minimal maintenance over time. Additionally, steel frame formwork facilitates efficient and rapid construction. Thanks to its modular nature and ease of assembly, it enables faster construction times, ultimately reducing the overall project duration. This becomes crucial in industrial construction, where time often plays a critical role. Finally, it is worth mentioning that steel frame formwork can be effortlessly disassembled and reused. This sustainability aspect makes it an environmentally friendly choice for industrial construction, as it minimizes waste and promotes resource efficiency. In conclusion, steel frame formwork proves to be a suitable option for industrial structures due to its strength, customization capabilities, durability, efficiency, and sustainability. It offers a reliable and cost-effective solution for the construction of sturdy and adaptable industrial buildings.

- Q: How does steel frame formwork impact the overall sustainability of a project?

- Steel frame formwork can have a significant positive impact on the overall sustainability of a project. Firstly, steel is a highly durable material, capable of withstanding harsh weather conditions and heavy loads. This durability ensures that the formwork can be reused multiple times, reducing the need for frequent replacements and minimizing waste generation. Additionally, steel frame formwork allows for precise and accurate construction, resulting in reduced material wastage. The modular nature of steel formwork systems enables easy assembly and disassembly, allowing for efficient and time-saving construction practices. This reduces labor costs and minimizes the project's environmental footprint. Furthermore, steel is a highly recyclable material, with a recycling rate of over 90%. At the end of a project, the steel formwork can be easily dismantled and recycled, reducing the amount of waste sent to landfills. This promotes a circular economy approach and contributes to the conservation of natural resources. Steel frame formwork also offers flexibility in design and adaptability to different project requirements. This versatility allows for the construction of complex structures, ensuring efficient use of space and resources. As a result, the overall sustainability of the project is enhanced by maximizing functionality and minimizing waste. In conclusion, the use of steel frame formwork positively impacts the overall sustainability of a project through its durability, reusability, recyclability, and design flexibility. By reducing waste generation, conserving resources, and promoting efficient construction practices, steel formwork contributes to a more sustainable and environmentally friendly construction industry.

Send your message to us

Adjustable SF120 System for Rectangle SF120-A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords