Custom SF63 Rectangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

concrete column formwork

aluminium formwork system

Adjustable SF120 System for Rectangle / Square Concrete Column

Description:

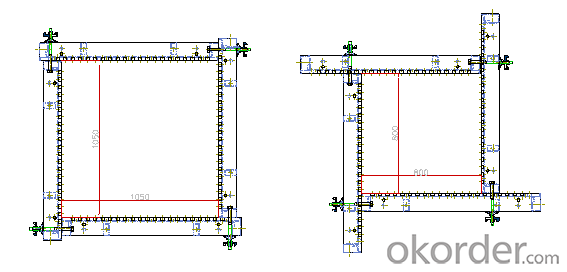

1. Structure sketch

SF120-A is a kind of formwork for pouring rectangle & square column; it is composed of formwork, props, adjustable steel clamp, etc.

Competitive Advantage:

1. High-precision production line guarantees the perfect products.

2. Special hollow steel frame covered with WISA-plywood, light weight but high strength.

Its allowable pressure from fresh concrete is 80KN/m2 with the weight of 65KG/m2.

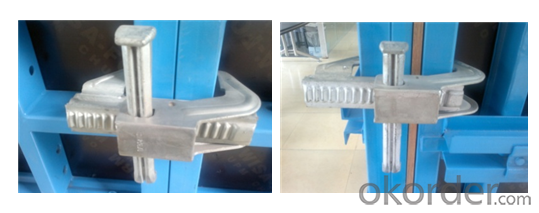

3. Easy connection with adjustable steel clamp.

4. The system is easy to change the cross section.

Applications:

- Q: What are the key safety features of steel frame formwork?

- Steel frame formwork offers several key safety features, including: 1. Enhanced Durability: Steel, being a robust and resilient material, can effectively support heavy loads and withstand external forces. This ensures the safety of both workers and the structure itself. 2. Unwavering Stability: The rigid structure of the steel frame formwork system provides excellent stability. It remains steadfast during the pouring of concrete, minimizing the risk of accidents caused by shifting or collapsing. 3. Effortless Assembly and Disassembly: The design of steel frame formwork allows for quick and easy installation and removal. Components can be effortlessly connected and disconnected, reducing on-site construction time and the likelihood of accidents. 4. Customizable Design: Many steel frame formwork systems feature adjustable elements, such as telescopic props and adjustable brackets. These allow for precise positioning and alignment, ensuring the formwork remains secure and stable. 5. Supplementary Safety Features: Steel frame formwork is often equipped with safety accessories like handrails, toe boards, and safety nets. These accessories provide additional protection, preventing falls and injuries to workers. 6. Fire-Resistant Properties: Steel is non-combustible, making steel frame formwork highly resistant to fire. This exceptional feature enhances overall construction site safety and minimizes the risk of fire-related accidents. 7. Exceptional Load-Bearing Capacity: Steel frame formwork is specifically designed to withstand heavy loads, ensuring the safety of workers and preventing structural failures. This is especially crucial in projects with significant load requirements or in high-rise constructions. 8. Seamless Compatibility with Other Safety Systems: Steel frame formwork can be easily integrated with other safety systems, such as scaffolding or fall protection equipment. This comprehensive safety setup reduces the risk of accidents and injuries on the construction site. In conclusion, the multitude of safety features offered by steel frame formwork makes it a dependable and secure choice for construction projects. Its durability, stability, easy assembly, customizable design, supplementary safety features, fire resistance, exceptional load-bearing capacity, and compatibility with other safety systems all contribute to creating a safe working environment for construction workers.

- Q: How does steel frame formwork contribute to the overall cost of a construction project?

- Steel frame formwork can contribute to the overall cost of a construction project in several ways. Firstly, it may require a higher initial investment compared to other types of formwork, such as timber or aluminum. However, this cost is often justified by its durability and reusability, as steel formwork can withstand multiple uses without significant wear and tear. Additionally, steel formwork can help to expedite the construction process by allowing for faster assembly and disassembly, reducing labor costs. Moreover, its strength and stability can minimize the need for additional support structures, saving on material costs. Overall, while steel frame formwork may have a higher upfront cost, its efficiency and longevity can result in long-term cost savings for the construction project.

- Q: What are the safety measures that need to be taken while using steel frame formwork?

- Some of the safety measures that need to be taken while using steel frame formwork include wearing appropriate personal protective equipment (PPE) such as safety helmets, gloves, and safety boots. It is important to ensure that the formwork is inspected regularly for any defects or damage before use. Workers should receive proper training on the correct assembly and dismantling procedures to prevent accidents. Adequate bracing and support should be provided to ensure stability and prevent collapse. Additionally, following proper handling techniques and using appropriate lifting equipment can help prevent injuries.

- Q: What are the considerations for selecting the appropriate formwork for different concrete curing methods?

- When selecting the appropriate formwork for different concrete curing methods, there are several important considerations to keep in mind. First, the type of curing method being used, such as traditional curing or accelerated curing, will play a significant role in determining the formwork requirements. For example, accelerated curing methods may require the use of insulated formwork to maintain the desired temperature. Secondly, the size and complexity of the concrete structure should be considered. Large and complex structures may require more robust and versatile formwork systems that can be easily adjusted and adapted to different shapes and dimensions. Additionally, the desired finish of the concrete surface is another crucial factor. If a smooth and uniform surface is desired, specialized formwork systems with smooth surfaces or form liners may be needed. On the other hand, if a textured or patterned surface is desired, formwork with appropriate patterns or textures should be selected. The time and budget constraints also need to be taken into account. Some formwork systems may be more cost-effective or time-efficient than others, depending on the specific curing method and project requirements. Lastly, safety considerations should always be a top priority. The chosen formwork system should be able to withstand the weight and pressure exerted by the fresh concrete, and it should provide adequate support and stability throughout the curing process. Overall, selecting the appropriate formwork for different concrete curing methods requires careful evaluation of factors such as curing method, structure size, desired finish, time and budget constraints, and safety requirements.

- Q: How does steel frame formwork ensure the stability of the concrete structure during pouring and curing?

- Steel frame formwork ensures the stability of the concrete structure during pouring and curing in several ways. Firstly, the steel frame provides a sturdy and rigid support system that keeps the formwork in place and prevents any movement or deformation. This is crucial because any movement or shifting of the formwork can result in a loss of shape and integrity of the concrete structure. Secondly, the steel frame formwork is designed to distribute the weight of the concrete evenly, ensuring that there are no concentrated loads or weak points that could lead to structural failures. The formwork is engineered to withstand the pressure exerted by the wet concrete, preventing any bulging or collapsing of the formwork. Furthermore, the steel frame formwork provides a smooth and level surface, which is essential for achieving a high-quality finish. The formwork is carefully aligned and adjusted to ensure that the concrete is poured at the desired level and with the correct slopes and angles. This not only enhances the aesthetic appeal of the structure but also contributes to its overall stability. In addition, steel frame formwork allows for precise control over the pouring process. The formwork is designed to be easily adjustable and reusable, enabling contractors to pour concrete in a controlled manner and in multiple stages if necessary. This control over the pouring process helps to prevent any voids, honeycombs, or other defects that could compromise the strength and stability of the concrete structure. Lastly, steel frame formwork provides a safe working environment for construction workers during the pouring and curing process. The formwork is designed to be strong and durable, reducing the risk of accidents or injuries. It also allows for easy access and egress, ensuring that workers can move around the construction site safely. Overall, the use of steel frame formwork is vital for ensuring the stability of concrete structures during pouring and curing. Its strength, rigidity, even weight distribution, precise control, and safety features all contribute to the successful completion of a high-quality and structurally sound concrete structure.

- Q: Are there any specific considerations for using steel frame formwork in high-temperature environments?

- Yes, there are specific considerations for using steel frame formwork in high-temperature environments. Steel has a high thermal conductivity, which means it can absorb and transfer heat quickly. In high-temperature conditions, steel formwork may expand, potentially leading to warping or deformation. It is crucial to choose steel with a high melting point and thermal stability to avoid structural integrity issues. Additionally, proper insulation and cooling measures should be implemented to prevent excessive heat transfer and minimize the impact of thermal expansion on the formwork system.

- Q: Are there any specific safety precautions to consider when using steel frame formwork?

- Yes, there are several safety precautions to consider when using steel frame formwork. Some of these precautions include: 1. Proper training: It is essential that all workers involved in using steel frame formwork receive proper training on its setup, usage, and dismantling. This training should cover topics such as load limits, safe assembly procedures, and how to avoid common hazards. 2. Inspection: Before using steel frame formwork, it is crucial to inspect it for any defects or damage. This includes checking for cracks, bent or damaged components, loose connections, or any other issues that may compromise its structural integrity. If any defects are found, the formwork should be repaired or replaced before use. 3. Stability and support: Steel frame formwork should be properly braced and supported to ensure stability during construction activities. This includes using appropriate props, ties, and supports to prevent the formwork from shifting or collapsing. 4. Fall protection: Working at heights is common when using steel frame formwork, so it is important to have proper fall protection measures in place. This may include the use of safety harnesses, guardrails, or safety nets to prevent falls and protect workers from serious injuries. 5. Load capacity: Steel frame formwork has specific load limits, and it is crucial to ensure that these limits are not exceeded. Overloading the formwork can lead to structural failure, collapse, or accidents. Proper planning and calculation of loads should be done to ensure the formwork is used within its safe capacity. 6. Communication: Effective communication among workers using steel frame formwork is essential for maintaining safety. This includes clear instructions, warnings, and signals to coordinate activities and avoid accidents. 7. Personal protective equipment (PPE): Workers should always wear appropriate PPE, such as hard hats, safety boots, gloves, and eye protection, to protect themselves from potential hazards associated with the use of steel frame formwork. By following these safety precautions, the risk of accidents, injuries, and structural failures can be minimized, ensuring a safe working environment when using steel frame formwork.

- Q: Can steel frame formwork be used in projects with limited skilled labor availability?

- Yes, steel frame formwork can be used in projects with limited skilled labor availability. Steel frame formwork is designed to be easy to assemble and dismantle, making it suitable for projects where skilled labor is limited. Additionally, steel frame formwork is durable and can be reused multiple times, further reducing the need for skilled labor.

- Q: Are there any specific considerations for using steel frame formwork in industrial construction projects?

- Yes, there are several specific considerations for using steel frame formwork in industrial construction projects. Firstly, steel frame formwork offers high strength and durability, making it suitable for large-scale and heavy-duty applications commonly found in industrial projects. Additionally, steel formwork provides excellent dimensional accuracy, ensuring precise and consistent results. It is also fire resistant, which is crucial in industrial settings where fire safety is a priority. Furthermore, steel formwork is reusable, reducing overall project costs and environmental impact. However, it is important to note that steel formwork requires skilled labor and proper maintenance to ensure its longevity and optimal performance.

- Q: Are there any specific considerations for using steel frame formwork in healthcare facilities?

- Yes, there are specific considerations for using steel frame formwork in healthcare facilities. Steel frame formwork offers several advantages such as durability, stability, and reusability, which are crucial in healthcare settings where construction needs to be sturdy and long-lasting. Additionally, the use of steel frame formwork allows for faster construction, minimizing disruptions to the facility's operations. However, it is important to ensure that the steel frame formwork meets all relevant safety and hygiene standards to maintain a sterile and safe environment for patients and staff.

Send your message to us

Custom SF63 Rectangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords