140 Type Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of 140 Steel frame formwork

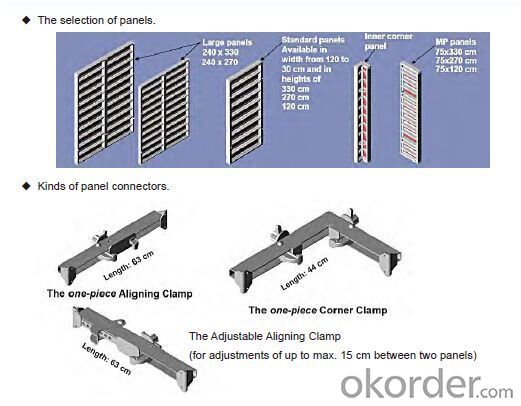

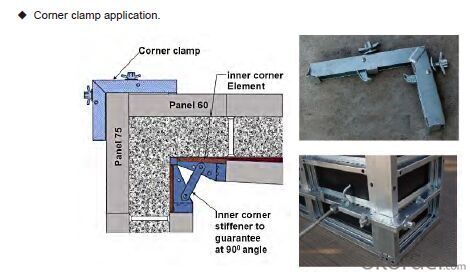

With adjustable flexiable sizes of frame, the 140 series steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean.

2. Main Features of 140 Steel frame formwork-Column formwork

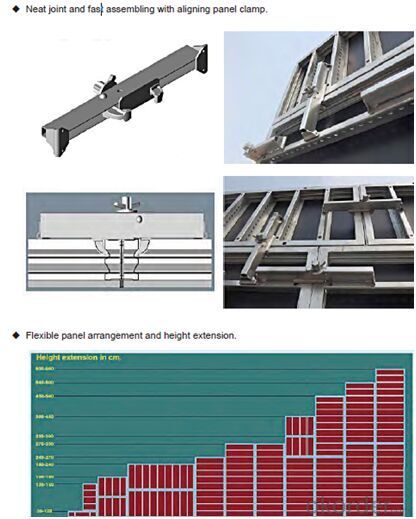

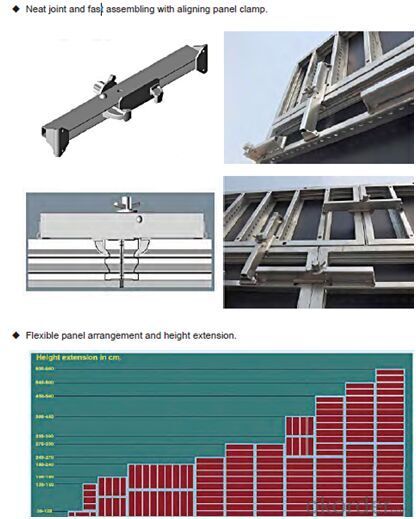

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 350px..

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

3. 140 Steel frame formwork-column formwork Images

4. 140 Steel Frame Formwork Specifications

5. FAQ of 140 Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the140 Steel frame formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Can steel frame formwork be used for both precast and cast-in-place concrete beams?

- Both precast and cast-in-place concrete beams can utilize steel frame formwork. This adaptable and sturdy system can easily be adjusted to different construction approaches. When it comes to precast beams, the steel frame formwork is employed to fashion the mold or template where the concrete is poured and left to solidify. Once the concrete has hardened, the formwork can be taken off, resulting in a precast beam that can be transported and installed at the construction site. Similarly, for cast-in-place concrete beams, steel frame formwork is used to create a temporary mold or template for pouring the concrete. The formwork provides support and structure to the concrete during the pouring and solidifying process. Once the concrete has set, the formwork can be removed, leaving behind a cast-in-place beam that becomes an integral part of the overall structure. Steel frame formwork offers numerous benefits for both precast and cast-in-place beams. It provides exceptional strength and stability, enabling the creation of beams with intricate shapes and sizes. The steel frame formwork is easily assembled and disassembled, making it efficient and cost-effective. Additionally, it is reusable, reducing waste and promoting sustainability in construction projects. In conclusion, steel frame formwork is a suitable option for both precast and cast-in-place concrete beams. Its versatility, durability, and user-friendly nature make it the preferred formwork system for various construction methods.

- Q: Can steel frame formwork be used for both straight and curved slabs?

- Indeed, steel frame formwork is applicable to both straight and curved slabs. This adaptable and pliable system readily adapts to various slab shapes and sizes. The steel frames effortlessly bend and curve to mirror the desired slab shape, rendering it suitable for both straight and curved slabs, effectively upholding stability and support during the concrete pouring procedure. Moreover, the reusability of steel frame formwork presents a cost-efficient resolution for a multitude of construction endeavors.

- Q: What are the different types of stripping methods used with steel frame formwork?

- There are several different types of stripping methods used with steel frame formwork, including crane stripping, hydraulic stripping, and manual stripping. Crane stripping involves using a crane to lift and remove the formwork from the concrete structure. Hydraulic stripping utilizes hydraulic jacks to lift and separate the formwork from the concrete. Manual stripping involves manually dismantling and removing the formwork by hand. These methods offer varying degrees of speed, efficiency, and labor requirements depending on the specific project and requirements of the formwork system.

- Q: Can steel frame formwork be used in curved or irregular structures?

- Yes, steel frame formwork can be used in curved or irregular structures. Its flexibility and adaptability make it suitable for shaping and supporting concrete in various complex geometries.

- Q: How does steel frame formwork contribute to the overall constructability of a concrete structure?

- Steel frame formwork contributes to the overall constructability of a concrete structure by providing a strong and stable framework for pouring and shaping the concrete. It allows for precise and accurate alignment of the formwork, ensuring the desired shape and dimensions of the structure. The steel frame can be easily assembled and disassembled, making it efficient for repetitive use and reducing construction time. Additionally, the steel frame formwork is durable and can withstand the pressure exerted by the wet concrete, leading to a high-quality and long-lasting concrete structure.

- Q: How does steel frame formwork handle the placement of reinforcement bars within the concrete structure?

- Steel frame formwork has been specifically engineered to manage the placement of reinforcement bars in concrete structures. This system consists of interconnected steel panels that form a robust framework, acting as a mold for pouring concrete. One of the key benefits of steel frame formwork lies in its ability to effortlessly accommodate reinforcement bars. The steel panels can be easily manipulated and aligned to create the desired shape and dimensions of the concrete structure, enabling precise placement of the bars. This factor is pivotal in guaranteeing the structural integrity and robustness of the concrete. Moreover, the steel frame formwork incorporates a range of features that aid in the correct positioning of reinforcement bars. For instance, it may include pre-drilled holes or slots in the steel panels, allowing for the insertion and secure fixing of the bars prior to pouring the concrete. Additionally, the formwork system can integrate specialized accessories like spacers or brackets to maintain accurate spacing and alignment of the reinforcement bars within the concrete structure. Furthermore, steel frame formwork offers exceptional support and stability throughout the pouring and curing process. The inflexible steel framework effectively retains the reinforcement bars in place, preventing any displacement or shifting that could jeopardize the structural integrity of the concrete. This guarantees that the bars remain in their intended positions and are completely enveloped by the concrete, maximizing their efficacy in reinforcing the structure. To summarize, steel frame formwork is purposefully designed to handle the placement of reinforcement bars in concrete structures. Its adaptability, versatility, and stability make it an ideal choice for ensuring precise positioning and effective reinforcement of the bars, ultimately contributing to the overall strength and durability of the concrete structure.

- Q: What are the considerations for selecting the appropriate thickness of steel frame formwork?

- When choosing the suitable thickness of steel frame formwork, there are several factors to take into account: 1. Load capacity: The steel frame formwork must be able to withstand the intended load, including the weight of the poured concrete and any additional loads like workers or equipment. It is crucial to calculate the maximum load and select a thickness that can safely support it. 2. Durability: The steel frame formwork should endure the construction environment, including exposure to weather elements, chemicals, and potential impacts or abrasions. Thicker steel frames generally offer more durability and resistance to wear and tear. 3. Span length: The thickness of the steel frame formwork should be suitable for the desired span length. Thin formwork may not be able to support the concrete weight over long spans, resulting in structural issues. Conversely, using excessively thick formwork for shorter spans may be unnecessary and add unnecessary weight and cost. 4. Construction schedule: The thickness of the steel frame formwork should also be considered in relation to the construction schedule. Thicker formwork may take longer to set up and dismantle, potentially slowing down the construction process. Striking a balance between the required strength and installation/removal efficiency is important. 5. Cost: The cost of the steel frame formwork is an important factor. Thicker formwork generally costs more due to the increased material required. It is crucial to evaluate the project budget and weigh the cost against the benefits of using thicker formwork. By carefully considering these factors, one can choose the appropriate thickness of steel frame formwork that fulfills the necessary load capacity, durability, span length, construction schedule, and cost considerations.

- Q: What are the different types of formwork braces used with steel frame formwork?

- There are several types of formwork braces that are commonly used with steel frame formwork systems. These braces are essential for providing stability and support to the formwork during the concrete pouring process. Some of the different types of formwork braces used with steel frame formwork include: 1. Kicker Braces: These braces are used to provide diagonal support between vertical members of the steel frame formwork. They help to prevent lateral movement and maintain the structural integrity of the formwork. 2. Horizontal Braces: These braces are used to connect the vertical members of the steel frame formwork horizontally. They provide stability and prevent the formwork from twisting or sagging. 3. Cross Braces: These braces are used to provide diagonal support in both directions, forming an "X" shape between the vertical members of the formwork. Cross braces help to distribute the load evenly and prevent any potential buckling or deformation. 4. Tie Rods and Waler Braces: These braces are used in conjunction with tie rods and walers to provide additional support and rigidity to the formwork. Tie rods are threaded rods that are inserted through holes in the vertical members and tightened with nuts to hold the formwork together. Waler braces are horizontal members that connect the tie rods and provide added strength. 5. Adjustable Braces: These braces are used to provide flexibility in adjusting the height and position of the formwork. They are typically made of telescopic tubes or adjustable rods that can be extended or retracted as needed to accommodate different concrete pouring heights. Overall, the different types of formwork braces used with steel frame formwork systems play a crucial role in ensuring the stability and integrity of the formwork during the concrete pouring process. They provide support, prevent deformation, and contribute to the overall quality and strength of the finished concrete structure.

- Q: How does steel frame formwork ensure proper alignment of columns and beams?

- Steel frame formwork ensures proper alignment of columns and beams through its rigid and accurate construction. The steel frame is precisely designed and manufactured to provide a strong and stable structure for the formwork system. Firstly, the steel frame formwork is designed to fit perfectly around the columns and beams, ensuring a tight and secure fit. This prevents any movement or shifting during the pouring and curing of concrete. The formwork is usually adjustable, allowing for easy alignment of the columns and beams to the desired position. This adjustability ensures that the formwork can accommodate different sizes and shapes of columns and beams. Additionally, the steel frame formwork provides a level and even surface for the concrete to be poured into. The formwork is usually equipped with adjustable metal props or jacks, which allow for precise adjustment of the height and level of the columns and beams. This ensures that the concrete is poured onto a level surface, preventing any unevenness or sloping in the final structure. Moreover, the steel frame formwork is designed to withstand the pressure and weight of the concrete during the pouring process. The steel frame is constructed with strong and durable materials, ensuring that it can support the weight of the concrete without any deformation or movement. This stability and rigidity of the formwork prevent any misalignment or distortion of the columns and beams. Overall, the steel frame formwork system ensures proper alignment of columns and beams by providing a rigid, adjustable, and level structure for pouring the concrete. It guarantees that the columns and beams are accurately positioned, resulting in a structurally sound and aesthetically pleasing final construction.

- Q: What are the main components of steel frame formwork?

- The primary elements of steel frame formwork are as follows: 1. Steel Frames: These serve as the fundamental components of steel frame formwork. They are crafted from top-notch steel and are engineered to provide stability and support while pouring concrete. The frames are typically modular and can be easily assembled and disassembled, making them incredibly versatile. 2. Plywood Panels: Plywood panels are utilized to construct the formwork surface onto which the concrete is poured. These panels are usually composed of high-quality plywood treated to be resistant to water and durable. The dimensions and thickness of the plywood panels may vary depending on the specific project requirements. 3. Tie Rods and Wing Nuts: Tie rods and wing nuts are employed to hold the steel frames together and ensure the stability of the formwork structure. The tie rods are threaded and can be adjusted to achieve the desired tension, while the wing nuts are used to secure the tie rods in place. 4. Adjustable Props: Adjustable props are employed to support the steel frame formwork and ensure that it maintains the correct position during the concrete pouring process. These props can be easily adjusted to the desired height and can withstand heavy loads. 5. Formwork Accessories: Various accessories such as clamps, connectors, and brackets are employed to connect and reinforce the steel frames. These accessories aid in ensuring the stability and integrity of the formwork structure. Overall, the primary components of steel frame formwork collaborate to create a robust and dependable system capable of supporting the weight of the concrete throughout the construction process. This type of formwork is widely utilized in the construction industry due to its durability, flexibility, and user-friendly nature.

Send your message to us

140 Type Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords