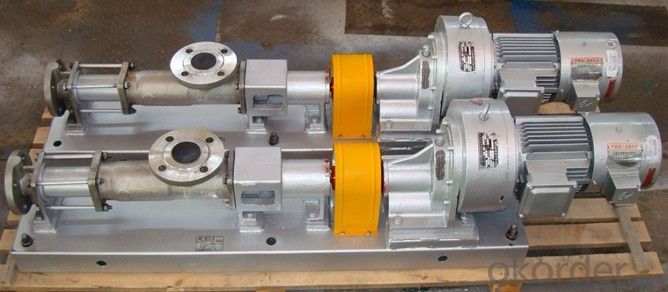

Rotary Progressive Cavity Monoblock Single Screw Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Series of Rotary Progressive Cavity Monoblock Single Screw Pumps

◆ XG 1/2 standard series Used for various structures

◆ XL 1/2long lead series Used for low pressure and large flow rate conveying

◆ XT 2/3standard lead series Suitable for high-efficiency conveying of medium and large pump

◆ XC 2/3long lead series Suitable for low pressure, large flow rate and high-efficiency conveying of medium and large pump

◆ XP Spraying pump series Used for slurry spraying in front of the coal water slurry boiler

Features of Positive Cavity Screw Pumps for Sewage Sludge and Polymer

Wide application, it can be used for conveying of flowing materials, even non-flowing materials

Continuous conveying, small pulsating quantity

The media is not stirred in the pump and is free from squeezing and cutting

The flow is in direct proportion to the rotating speed, variable output, measurement feeding

Elastic stator, certain abrasion resistance

Conveying Medium of Positive Cavity Screw Pumps for Sewage Sludge and Polymer

Various viscous media (the highest viscosity reaches 106 mm2/s)

Fluids with various concentrations and dewatered and dried materials

The media containing solid particles, fibers and suspended solids

Horizontal Direct Linking of Positive Cavity Screw Pumps for Sewage Sludge and Polymer

Features: It is directly driven by gear motor, compact structure, short length of the pump

Parameters: 600m³/h; maximum pressure: 2.4MPa or higher

FAQ

Are your pumps protected against dry running?

No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

How can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

- Q: looking for the comparison and then finaly the conclusion about the water pumps instaaled in the IC engines. Where we should stick to the tradional mechanical driven water pumps or electrical water pumps? which one is better!! any information/ response is appreciated

- Duh (I have to assume that IC = a engine (as fitted in a car) if there's no fan belt, how would YOU drive a water pump? I suggest the person that asked the question has PEDALS fitted to his/her IC the fan belt went when radiator fans had motors added (which was good as the fan was a unwanted load on the engine ...you only need a fan when stationary)

- Q: Pump frequent start will reduce the service life, I ask what kind of frequency is called frequent start?

- How to define this frequently, this can only say, for example, the life of the switch is 60 thousand times, once every hour you move, it can be used for a long time, and that if you move one minute, it would not necessarily for long.Pumps frequently start the first self wear problems, as well as the impact on the pipe network, especially the soft connections.Water pump if the frequency of use or time, it is recommended to adopt: variable frequency constant pressure control.

- Q: Pump adapter joint net outside tube, what is the principle?

- At once the room after the fire, the internal fire pool once water shortage, the water tank can be within the fire truck hit the water chamber through the pump adapter connected to the fire extinguishing effect.

- Q: I bought a new water pump for my 89 S10 Blazer with the 4.3 V6. The guy at Autozone wanted to know if I wanted a standard one or the heavy duty. I bought the heavy duty one because it was only $5.00 more. Are they just built stronger or do they actually move more water?

- The intense flow in simple terms strikes greater water in line with revolution the a manufacturing facility pump. Heavy accountability must be the comparable because of the fact the hi-flow, whilst the electrical powered pump would not use the fan belt to coach the pump, this is have been given a small electric powered motor to try this. See if there is any distinction between hi-flow heavy accountability, get one in all those.

- Q: Two sewage pumps switch from each other, start with float switch control, the first sump, when the water is full, the first start, the second rotation to second units start, so the cycle of alternating

- The puddle is full, the float switch is closed, and the relay J1 works to drive the first motor. The J1's work makes the intermediate relay 'J' work and locks itself, preparing for the work of the second machines. The water level is lowered to the required minimum position, the ball is broken, the motor is stopped and the motor is stopped. When the water level rose to the highest position again, the floating ball closed again, the relay J2 and self-locking relay J2 to drive second motors, instant intermediate relay are opened, when the water level again be reduced to the lowest position, float off, the motor stops working, stop by working in front of the intermediate relay. The whole circuit back to the original state. So that the two motors work alternately.It should be noted that the circuit diagram for simple to understand, only painted the control circuit, there is no main circuit, there is no missing phase, leakage, over-current and other protection, the actual installation needs to be installed. There is the role of time relay is to ensure that the relay J2 normal work, the intermediate relay is disconnected, so that the motor 2 does not occur wrong action, time relay can be set to a few seconds, or even less than a second. Intermediate relay can also be controlled by time relay, and its time is also set very small, so as to avoid J2 short time possible power supply.

- Q: About 2 months ago I started hearing a noise coming from my bathroom that sounded like loud humming every 3 or 4 seconds after I would turn on the water or flush the toilet. I noticed that when this noise happened the water pressure would increase and then it would go back to normal. Then the noise started to get louder. Last night while my husband was taking a shower the water lost pressure and then completely turned off. Now I have no water at all whatsoever except for maybe a few drops when I turn the faucet on. I have a private well and when I bought the house I was told that the well is underneath one of my bedrooms because the house was built on to and they built over the well. I know I can get to the pump from the crawl space. Has anyone had this problem or does anyone know what it might be or maybe even how much it could cost to fix?

- can you take pump apart an clean

- Q: My car overheats in hot temperatures I have try everything except replacing the water pump and radiator how can I tell when its time to change each one and is it a do-it-yourself job

- Water pumps are very simple. They only fail if 1) They spring a leak, 2) Their bearing freezes up, or 3) Their drive belt breaks or slips. I'd suspect the thermostat first, a clogged radiator second, or a bad electric fan or relay. They are easy to replace on most pre-1960's cars, and a complete hassle on many newer models. Good luck with the project.

- Q: I have a quot;Rainbow Lifeguard Quiet One 6000external pump that I would like to use on a new chiller for my tank. The pump is rated at a little over 1500 gallons per hour. I'm debating between a couple of chillers, one that has a max flow rate of 1300 gph and another that has a max of 960.I know that you are only supposed to put any valves on the outflow side of the pump and lessening the flow to 1300 from 1500 doesn't seem like it would be that big of a problem, but I was curious it cutting it back to 960 would be hard on the pump in the long run. (I'm leaning towards the bigger chiller as although it may be overkill for my tank, it would let me have a little more water circulation.)

- ditto to magic

- Q: I have a 2002 Honda Civic Ex sedan with about 105k miles. Sometime before 110k I need to get the timing belt replaced. At about 95k my mechanic asked if I wanted to replace the timing belt and the water pump. According to the owners manual the timing belt must be replaced, but it simply says check the water pump.I don't want to pay for unnecessary repairs, but I also know that both of these jobs are quite involved, but can be done together fairly easily. Is there anything I can do to check myself or do I just have to trust my mechanic when I take it in. Also, what is the cost difference between the timing belt job and adding in the water pump at the same time?

- i would if i were you. that way you will know everything is good shape. besides a pump don,t cost that much.

- Q: I'm curious to know, where does the water go after it is sent to a pumping station??

- Potable (drinkable) water pumps placed just outside the treatment plant boost pressure in the water mains, where it eventually gets to homes, businesses and hydrants via the pipe network. Most sewers flow by gravity (downhill) to a waste water treatment plant (or septic field). But if an area is too low to be serviced by a gravity sewer, an ejector pump is set at the bottom of a collection well which pumps the wastewater to a higher elevation in a pressure pipe called a force main. A good pump station will kick on about 4 or 5 times an hour and run for several minutes. Eventually it outlets to a manhole in a gravity system and ultimately the treatment plant.

Send your message to us

Rotary Progressive Cavity Monoblock Single Screw Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords