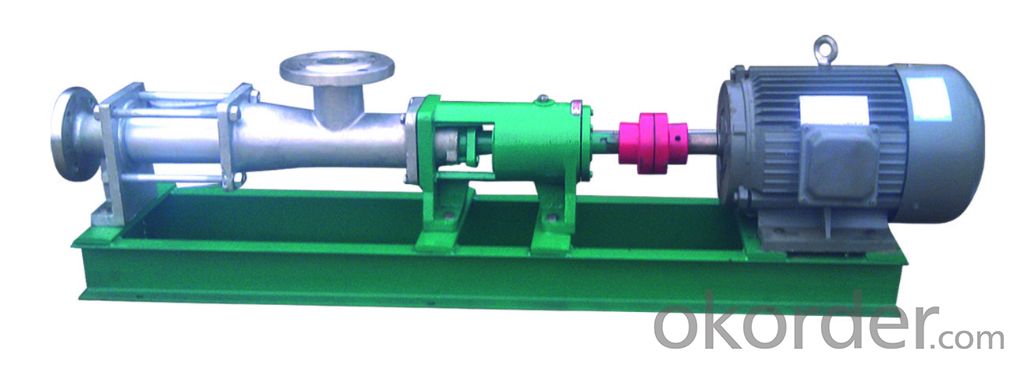

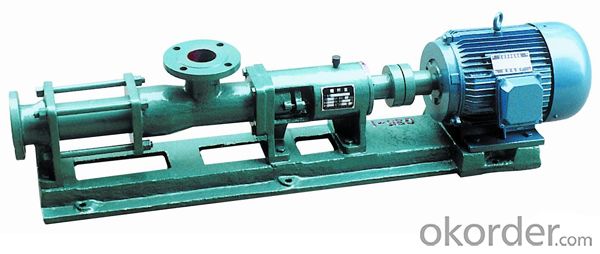

Electrical Single Screw Pump for Corrsive Medium

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GERNERAL

The series G of Single Screw Pump is a rotating mesh and positive displacement pump.

The main working parts are the Eccentric Screw ( Rotor ) and the Bush fixed ( Stator ).

With the special geometry of these two parts, dividing the cavity into two independent sealed chambers.

Fluids flow to the direction of axis with low flow rate, and the volume and pressure remain stability,

so it will not have swirl and stir inside.

OUTPUT PRESSURE: 0.6Mpa for each class of pump

HEAD: 60M for water

SUCTION PRESSURE: 0.6Bar

TEMPERATURE: MAX . 80°C . It can reach to 150°C for special request.

FLUIDS: For transporting high viscosity, hard suspended partilcles and fiber with its varity of flexible materials.

And the flow rate is proportional to the speed.

ELECTRIC MOTOR COUPLING: It’s direct and you can use motor speed, wedge shaped belt and transmission case etc. to shift gear.

FEATURE: Fewer accessories, compact structure and facilitate maintenance. The rotor and stator are easily damaged parts. But don’t worry, it’s easy disassembly for its simple structure.

Application

Single Screw Pump of series G is a kind of Gerneral Pump. Its speed can be switched freely and its output rated pressure can be increased by its level. The pumps can be widely used in many different areas.

Especially to be emphasised in the application in plant s of:

Environmental protection:

oilwater separator,plate and frame filter press for conveying industrial sewage, domestic sewage and sludge and filth which contain solide particles and short fibers

The shipping industry:

the bottom of ship cleaning, plants for conveying oil-water, oil-residue and oily sewage.

The petroleum industry:

oil delivery In recent yeas, it pumped mixture of oil and water, coal field gas and water from the kilometres’ deep undergroud successfully so that greatly reduced the cost. Then you can use the screw pump to pour polymer into layer to increase the efficiency of the exploitation of oil fields by the late time.

The medical and daily health product industry:

plants for conveying dope, oil water emulsion and salve cosmetics.

The canned food industry:

plants for conveying viscous starch, edible oil, honey, syrup, fruit puree, cream, minced fillet and minced meat and their residues.

Brewing industry:

plants for conveying viscous liquid fermentation, thick lees, residue of food product, all kinds of syrup and paste and mucus which contain blocky solid matter.

The construction industry:

plants for conveying cement mortar, lime mortar, coating material and other pasty material.

The mining industry:

plants for discharging groundwater and sewage which contain solid particle to the surface.

The chemical industry:

transport all kinds of suspension, grease, colloid and adhesive

The printing & paper industry:

plants for conveying high viscosity painting ink, PVC high molecular plastic paste of wall paper, paper pulp and short fiber stuff.

NOTES

Make sure the running direction before starting the press.

Do not operate it without any fluid in sake of protecting the stator.

Do not start the pump immediately when it just installed or stop it for several days. Please pour some engine oil intothe casing first and use pipe wrench to running some laps before you start the press.

Please wash the pump by water or solvent after conveying fluids with high viscosity , solid particles and corrosive.

Please clean out liquid loading in winter in order to avoid frost cracking.

Please add lubricating oil regularly into the bearing house during the operation. If you find some leakage at the shaft end, please deal with it in time and change the oil seal.

Please stop the pump immediately if you find something unusual happened during the operation, check it up to trouble shooting.

- Q: Ok, here's my problem. My parents bought this house a few years ago. No problems at first, but then during Hurricane Katrina, the basement started to flood from the heavy rains. Now whenever it rains, it floods. We have a half bath down there and the water would drain out in the shower drain. Now no water drains out, and we've already check the drain for clogs. It's clear. We currently have to bucket the water out.I'm looking for a good water pump to get them before I move out. I'm not sure if it has a sump pit or anything.We don't particularly care if we have to pump it out through a window or anything, as we have a pasture next to us. I just need something that could pump out the water when it rains. Preferably something not too expensive but that will still get the job done.Note: This is in Louisiana; lord knows what compelled the people who built this house to build a basement.Any suggestions/advice are much appreciated.

- hydromatic okorder /.. ~Honsell T- the reason he has water entering his basement is because he lives in Louisiana(or anywhere in the south really), which is at or BELOW sea level. you have to have serious waterproofing to not have leaks.

- Q: I'm planning to install a water pump using electric generator from a very long distance going up from a cliff

- Well yes it wiould , powerful pumps need more electric power so check that the generator can supply the power needed by the pump

- Q: How do I change the water pump on a 2003 PT Cruiser. What do you do with the timing belt and gears?

- if you have 100,000 miles on it, and haven't changed the timing belt, CHANGE IT NOW. Recommended change at 100,000 miles. Mine broke at 104,000, towing was $125, and then cost of repairs. Also recommend changing seals on xmission at same time.

- Q: it was fine before the water pump was done garage says it is just a coincidence? but could the water pump effect the heating?

- no it's not... I would take it back and make them fix it right

- Q: I am a business man.My Instituate name is Rockydockyard.This Institiate build up Ships,containerships etc.So we found a high pressure water pump.

- You okorder /... and in collage then you say you have an Instituate or was that Institiate? You probably ought to finish grade school. Then maybe you can find a girlfriend. She may even have a high pressure water pump!

- Q: I am trying to change my daughters 2004 Grande Am water pump because people tell me it is squealing. We purchased a replacement pump and blue gasket glue. I know to remove the Serpentine belt (not sure which pulley to reduce tension on) then I need to know which bolts to un-tighten, won't the pump turn as a use the wrench? Is there a good video available on changing out the water pump? I've done maybe 5 water pumps in my lifetime all on V-8s with rear wheel drive, so they had easy access. Does anyone know the steps of removal or can someone point to a video of removal replacement?

- better make sure it,s not the belt squealing and not the pump. usually when a water pump goes out they will leak. i would be checking the belt first.

- Q: I would like to pump water from a canal which is approx. 65ft from my existing sprinkler plumbing. the height of the water level on average is approx. 6ft from the surface of the ground. I will need about 35 psi to operate the sprinkler zones. would the following pump work given the lose of pressure?... Horsepower:1.5Voltage:110V 60hz 9.5AmpPower ( max ):1100 WMax Flow :330 L/Min (87 GPM)Suct Hmax9M(30ft)Max Head:18 MInlet/Outlet Size:1.5quot;RPM:3450

- it almost has to. the max amperage for anything with a 110 volt plug is about 12.5 amps. it should as long you are not pumping the water uphill. Please give me the 10 points for best answer!!

- Q: I have a 1999 Volkswagen Passat and the water pump seems to be leaking. The lower radiator hose has been replaced but it still leaks a fairly substantial amount. From what I can tell the pump is still doing its job but I'm losing coolant. Is there a way I can determine if i just need a new gasket or a new pump altogether without ripping the front end off? Any feedback is appreciated.

- Replace the pump. While your at it, since the front end (actually the bumper cover) is off, get the timing belt done, with rollers, tensioner, thermostat, and G12 coolant.

- Q: I have a 2001 2500HD duramax and it is leaking antifreeze under the truck. I leaks a a drop every second what could be causing this

- If you can narrow down the location to being from the actual water pump and not a line, It would be the seal in the water pump. The only option is to replace the water pump.

- Q: the water pump from the factory has an extra hole coming out the side its the smaller one on the end of this pic.

- This is your recirculating pump. If it is a marine pump, it will have a brass backed seal and no heater hose outlet. (have seen them in the casting, but no hole there) The only difference is the casting, as long as it was ordered for the boat, you should be OK. For got to ask, do you have a cabin heater in the boat?

Send your message to us

Electrical Single Screw Pump for Corrsive Medium

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords