Hot Selling Single Stage Rotary Vane Vacuum Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Stage Rotary Vane Vacuum Pumps

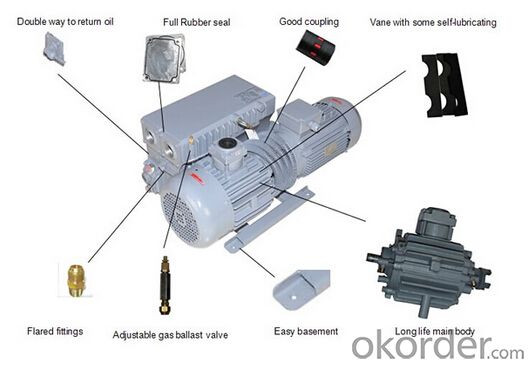

1.Structure of Single Stage Rotary Vane Vacuum Pump

single stage rotary vane vacuum pumps combining with many years of experience in vacuum engineering and the latest international vacuum technology developed to meet requirements of both the industry and the environment.They are being used in all areas of vacuum engineering. They are equally suited for both industrial production and research applications. They may be used to generate a rough and medium vacuum or as backing pumps in pump combinations with Roots pumps or high vacuum pumps. The comprehensive range (pumping speeds ranging from 10 to 630 m 3 / h) allows every customer to select the right pump for his particular needs.

2.Main features of Single Stage Rotary Vane Vacuum Pump

• Long life design

• The comprehensive range from 10 to 630 m 3 / h

• Vacuum pump entirely replace the pumps like U3/U4,R5,VC,EU and etc.

• High pumping speed also at low pressures

• Optimum price-to-performance ratio

• Low noise level

• Low vibrations

• Integrated exhaust filter, up to 99.9% efficient

3.Single Stage Rotary Vane Vacuum Pump Images

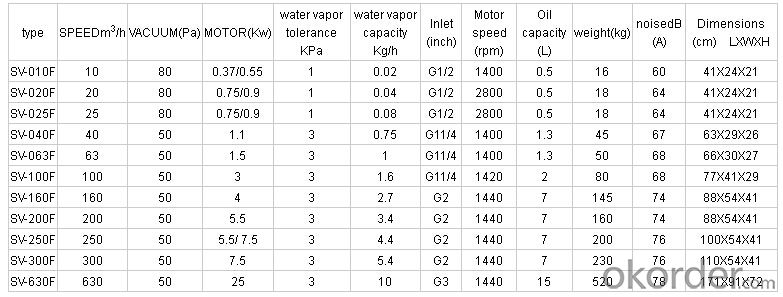

4.Single Stage Rotaty Vane Vacuum Pump Specification

5.FAQ

①Application

Food industry , Vacuum packaging, Material drying, Car industry , Furnaces and plants , chemical, Laser technology , Medicinal technology , Metallurgy , Power engineering , Space simulation , Vacuum coating , vacuum loading, electronics, semiconductor, scientific research

- Q: Fire pump and shower pump flow head selection, high resolution.

- Selection of flow head of fire pump and spray pump:1, the volume is greater than 5000 is less than 10000, the minimum water consumption of indoor fire hydrant is 10L/s

- Q: Is the diaphragm pump and the drain pump one?

- Therefore, the need to play a liquid discharge pump, if the medium is corrosive liquid, high viscosity, volatile, flammable, highly toxic liquid, you can choose diaphragm pump. Conversely, the general liquid, there is no special requirements, you can use the general centrifugal pump to reduce costs.

- Q: Double floor sewage pump circuit diagram of a small problem

- Question 4 when you need backup, you need to switch the SA switch, but where you want it. For example, when the 1# pump is running and does not reach the high water level, the 2# pump will not operate. If SA is placed in the left position, 21 and 22 are connected, and the KT is electrically delayed, and the KAB action causes the 2# pump to function. After the KAB operation, the KT will be disconnected, restored to the ready state, and also convenient for KT to restart the power on time, and also avoid the time relay to work on a long-term basis.

- Q: What does "efficiency" mean in a water pump catalog?

- Pump efficiency: the ratio of the effective power and the pump shaft power

- Q: What are the parts of a pump? How do you classify it?I just want to know

- Before opening the pump suction pipes and pumps must be filled with water. Open the pump, the impeller rotating speed, which leaves the liquid together with the rotation under the action of centrifugal force, the left outside impeller injection, injection of the liquid in the pump shell gradually slow the spread of indoor speed, the pressure gradually increased, and then from the pump outlet. The outflow discharge tube. At this time, in the leaves at the center of the vacuum area of low pressure liquid was thrown to the surrounding formation there is no air and no liquid, liquid pool at the surface of the liquid under the action of atmospheric pressure, through the suction pipe into the pump, the liquid is continuously pumped up from the liquid pool is also continuous outflow from the discharge pipe.Mainly by the impeller, pump shell, pump shaft, bearings and packing sealing devices and other components

- Q: What's the word "pump"? Is that what advocates mean?RT

- The words should be decided by the object that everyone supports. The supporters are called "fans"; those who support the singers are called "fans"; the people who support "stars" are called "fans". If the idol supported by everybody is called "shadow" and "view",Star of song? It can not be called "what fans", can only be called "fans"!

- Q: Why is the sewage pump device coupler?

- Advantages of installation and arrangement of sewage pump coupling:1. automatic coupling device, easy installation and maintenance. In the absence of automatic coupling device under the condition of fixed installation, such as pump fault maintenance personnel need to unscrew the screw pump lifting water, repair, or other small pump to pump the water down perfect maintenance, if the water is dirty, it would be difficult for people to go to the next, then the overhaul had great difficulty.

- Q: Why does the centrifugal pump start with a closed valve and the axial pump starts with an opening valve?

- Centrifugal pumps require a vacuum to produce negative pressure, which allows atmospheric pressure to lift the water surfaceAxial flow pump impeller is thrust on water

- Q: Because the water pressure of the booster pump is not enough, it can not work automatically. It can only be operated by hand. It is inconvenient to use.

- The worst case is that the pump is not automatic when it leaves the factory, and no one can say whose product is 100%.But there may be automatic control of this piece, not debugging (this depends on the specific product manual or manufacturer)

- Q: What is the difference between an air pump and a water pump?

- Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

Send your message to us

Hot Selling Single Stage Rotary Vane Vacuum Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches