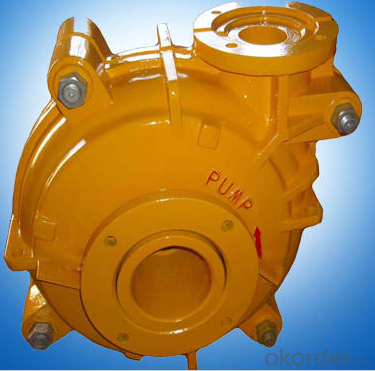

Wear Resistant Metal Lined Slurry Pump For Mining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

China Manufacturer

Abrasion & corrosion resistant

AH,HH,M,G series

Design and select pump for projects

Different pump parts

Slurry Pump For Mining

Slurry Pump For Mining Feature:

1) Cantilevered, horizontal, centrifugal, single stage

2) Widely application: the slurry pumps are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

3) Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

4) Wear resistant and anti-abrasion wet parts: The wet parts can be made of hard metal (26-28% Chrome alloy) or different rubber. They are completely interchangeable with AH series pumps. More materials are also available.

5) Easily replaceable liners: Liners are bolted to the casing.

6) Simple maintenance throat-bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple.

7) Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

8) High efficiency and high head design are also available.

9) Centrifugal seal, mechanical seal and packing seal are available.

10) Welcome OEM

11) ISO 9001-2008,CE

- Q: i have well water. suddenly i'm getting more pressure in my water. I have a well siofterner system. does anyone know what could be causing more pressure to come out from the water?/ thanks alot.

- too much pressure in your pressure tank bleed some air out. reset pressure.

- Q: Have a Toyota RAV4. About 156, 000 miles on it.Yesterday as I started driving, there was a sound coming from underthe hood that sounded similar to a stick in bicycle spokes. Got to theend of the block and stopped and noticed there was smoke comingfrom below the belts.Got back to the house and the temp was up really high. No fluid.Added fluid and water and it was leaking, but not from the radiatoritself, but from towards the back of the engine?Might this be the water pump?

- My dad and i were driving our mitsubishi eclipse and then we stoped a parking space to go to the store al of the sudden something popped and it stared smoking and a bunch of water came out yes it was the water pump we got a new one and it started working fine try that.

- Q: What is the meaning of "ETA" in pump selection table, the unit is%; and what does "NPSH" mean? The unit is m. Is in the south water pump performance curve appeared, please refer to the master, and now thank you.

- NPSH refers to the cavitation, the pump is the technical parameters

- Q: i replace all the seals on the water pump reinstalled it and the same thing happened... it leaks out the bottom some where and run down the water pump and down the hot side radiator hose... any ideas?

- look up the torque spec's in either a hayne's/chilton's manual, or online to see if you have it tightened correctly, and using some high-temp RTV on both sides of the gasket before you install it should help. most auto part stores have torque wrenches to rent for a day. Also, there may be a certain order you have to tighten the bolts down.

- Q: What causes a water pump on a car to go bad????? and are they a pain to change by yourself?????

- Bearing siezes/ Housing leaks/ Seals wear out. All do to use, expanding/contracting due to heat and cool down, and time also. Just a side note for Bryan K a car being FWD or RWD has no bearing on how much room you have for the waterpump or vice versa. This is a generalized statement that holds no truth. I'll give you one example that makes that statement false : when replacing a timing belt/water pump 96-01 Audi A4 1.8t 4cyl the entire front bumper and support must be removed in order to gain access to the timing belt and water pump. However this method is true for both FWD/AWD models. 99.5 to 2004 volkswagens have the same 1.8t engine but they are not longitudinally orientated the water pump and timing belt can be accessed fairly easy a lot less labor than the audi and the jetta is also available in FWD and AWD. Before someone contradicts the AWD jetta look up 4motion volkswagens. There are not alot in the states but they exist. Thanks for allowing me to throw inmy two cents in correcting generalized truths that are not true.

- Q: Water is pumped upwards 4.000 m into a pool. The flow rate of the water is 4.000 L/min and it takes 10.00 minutes to fill the pool. What is the power of the pump?I would appreciate any help that you can give me - this is a question on an upcoming test!

- g = 10m/s^2 1 : Mass of water per Minute = 4 * 1000g = 4Kg Mass of water per second = 4Kg/60 Height = 4m Work per second = m(per second) g h = Power Power = 4/60*10*4 = 160/60 W = 2.6666W 2: Total Mass of water = 4 * 1000g * 10 =40Kg Height = 4m Work Done = mgh = 40*4*10 = 1600j Power = Work/Time = 1600/(10*60) = 2.6666W This is a Very Small Pump :P Hope this Helps Kaushalya Damitha

- Q: After I replaced the water pump impeller in my outboard I fired up the motor and now its not pumping any water through the pee-hole at all and also the prop is spinning in the neutral position (motor seems as if it is in gear and trying to move). Would this be because of the shift rod or the drive shaft not being in the proper position and possibly the impeller is being span the wrong in the impeller housing cup?

- First the impeller -- did you find all of the old one, or are a couple of vanes missing? When you disassemble to put on a new impeller, you must account for all of the old one -- pieces like to be pushed by water into the cooling passages. I like a thin stiff springy wire to run through the pee-hole and up into toe water pickup tube. If you can blow air through the tubes, they aren't blocked. Did you put the impeller on upside down? It only works one way -- as it spins, the outer ends of the vanes should follow the vane, not lead it. When you reassemble, you must get the gear set aligned properly -- When it's assembled properly, the prop will be locked in forward and reverse but will freewheel in neutral. You must turn the blade so the flat of the clutch dog faces up, with the shifter in neutral, as you assemble it. Try it a couple times, you'll figure it out.

- Q: My dad wants to buy a salt water pump for a tiny pool.I'm not sure if it's pointless for the size that the pool is, but it is 12x12x3Is it too small of a pool or are there salt water pumps meant for tiny pools that I could look at?A link to any would be nice. :)Thanks!

- salt okorder /

- Q: Hi -- could someone please give me information on how much I should expect to pay for a water pump and to cleanse my coolant system (or something like that) or if it's something I really need to do. Or if I can get the water pump without the coolant system...My car is running fine, just started making kind of a rough running sound a few weeks ago when it's idling. ANY advice is greatly appreciated!

- If okorder /

- Q: Do you need a stop valve for the pump at home?

- Pump used at home do not take the water stop valve, the water level is too low, it can not pump up. In addition, there is no stop valve, not immediately pumping water, will have to wait a short time.The valve is actually a floating ball valve, when water is accumulated to a certain height, the float top, open the valve linkage; row water, reduce the water level, the valve is automatically closed, it realizes automatic drainage to steam pipeline.

Send your message to us

Wear Resistant Metal Lined Slurry Pump For Mining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords