High-speed Installation Tunnel Steel Template

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

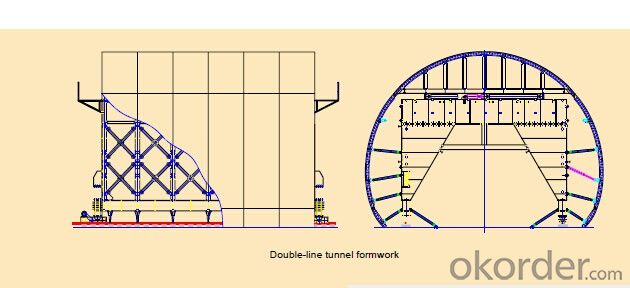

TUNNEL FORMWORK

The automatic hydraulic tunnel formwork is the equipment to make

the concrete lining for the tunnel in one time.The empty gantry allows the

transport vehicles to pass. The motor gearbox is adopted to drive

the whole equipment, the formwork is fully hydraulic, with hydraulic

cylinder to prop & strip, and lock mechanically

◆ Good concreting quality

◆ High-speed of installation and removal of the form

◆ Easy operation and safety

- Q: 1 tunnel lighting design steps, 2 teacher said to design a template, is not to create a tunnel, and then according to the numerical calculation of what?

- When the light into the human eye increases, the pupil contraction, when the surrounding environment becomes dark; into the human eye when the light is reduced, the pupil increases.

- Q: The tunnel structure of plastic mould

- In the use of the whole tunnel mode is not as flexible as semi tunnel mode, the lifting equipment requirements are higher, it is gradually being semi tunnelMode substitution.

- Q: The tunnel lining is wood, how should support?

- The excavation of the tunnel face, slag, to the primary support system, first hit the bolt, then use steel or steel made of steel, installation support in tunnel contour, and then sprayed concrete (poor surrounding rock hanging steel mesh, then sprayed fiber concrete).

- Q: What is the role of the grid steel frame and steel mesh in the power tunnel

- Advanced small pipe grouting small catheter with a diameter of 32-50mm steel pipe, the pipe tip and tube holes for special processing. The first row with drill drilling pipe. Row spacing is 30cm, fan shape, elevation of 5 degrees to about 8 degrees. The length is 2.25m, a single fluid grouting (cement) or double grout (cement water glass slurry). Adjust the grouting pressure according to the soil.

- Q: Design of lining concrete is C30, what should be used in the construction of concrete arch cushion concrete?

- The thickness of the cushion should not be less than 70mm, and the concrete strength grade should not be less than C10;

- Q: What is the role of the tunnel formwork trolley? What is the use of template trolley?

- The use of full circle wear line; side and roof arch lining are most commonly used, two concrete lining construction commonly used in highway, railway tunnel and underground cavern.

- Q: Tunnel construction procedure A cycle of steps

- Tunnel construction process, the first branch is a temporary payment, two lining is a permanent support.1, the hole before the edge, the construction of the slope (including drainage, electricity, etc.);2, the construction of large pipe shed3, measurement positioning line;4, drilling, blasting;5, slag, playing anchor, steel, injection (including the initial spray and spray)6, ahead of the anchor (after the pipe section)7, measuring the line;

- Q: In the tunnel construction, the water stop belt and the water stop strip are respectively used in what place, the construction joint and the subsidence seam many meters set a, above all has any function

- 5, the user should be based on the order of the project structure, design drawings to calculate the length of the product, the special-shaped structure should have drawings, as far as possible in the factory will be connected to the whole

- Q: A detailed method is introduced

- 5) the construction of open cut tunnel reinforced concrete structure construction is divided into two parts: first, the construction of inverted arch and wall foundation of reinforced concrete, to be part of the concrete reaches certain strength, stripping, cutting hair construction joints, and construction of the upper side wall and arch of reinforced concrete. The inverted arch and wall part of the composite steel formwork, artificial pouring, side wall and arch concrete construction formwork for the internal mold, and molded with combined steel formwork, formwork and external bracing to ensure stable, symmetrical pouring concrete, steel processing plant in processing molding, binding site. The concrete is produced by the automatic metering concrete mixing station, the concrete transport vehicle transportation, the concrete pump into the mold, the insertion type tamping device is compacted, and the arch wall concrete is completed once.6) water proof construction, laying waterproof layer, tunnel construction on the surface of concrete repair chisel flat uneven place to prevent damage of waterproof board. The weld quality of the waterproof board shall meet the requirements. If there is any defect, corrective action must be taken to meet the requirements.7) arch backfilling: Myeongdong vault above maximum backfill height 2m, compaction degree '93% fill in the top-level clay layer of water, the backfill surface of turf.Back fill both sides of the symmetry at the same time, the bottom of the wall filled with 0.5m ~ 1m thick gravel and compacted, and then the use of artificial layered backfill, layer by layer compaction. Careful protection of the waterproof layer during backfilling is not destroyed.The water layer of clay and the side, the slope of the lap is good, close to prevent surface water leakage.

- Q: I would like to ask the high-speed rail tunnel invert small side wall and arch with the small side of the wall of the hanging formwork of what a good method?

- Die casting. Install the inverted L hanger on the side wall.

Send your message to us

High-speed Installation Tunnel Steel Template

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords