building tunnel formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

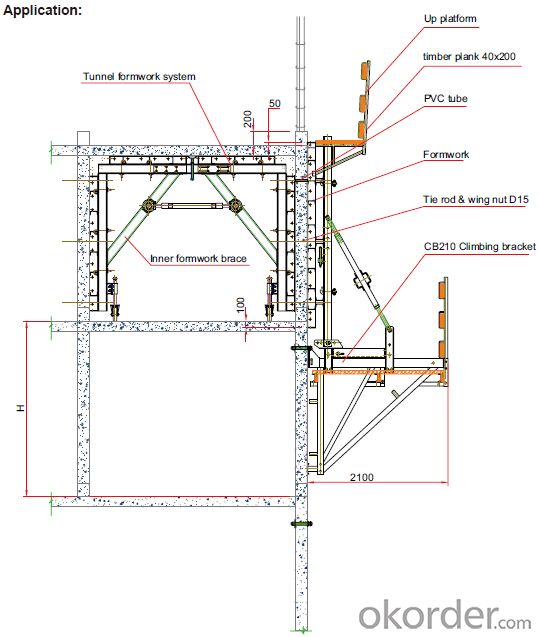

Building Tunnel Formwork:

A compositional steel formwork system mainly used in the building which has regular structure

without beams, the excellent formwork system can make the integral pouring for the wall & slab

easily achieved.

Characteristics:

◆ High stiffness, make perfect shape for concrete.

◆ Easy operation, save labor and force.

◆ Fast forming, repeatedly turnover.

- Q: The tunnel structure of plastic mould

- Tunnel construction, due to the wall and floor can be cast at the same time, therefore, the design of the building has the following requirements.(1) the width and height of the room should be relatively constant, and the thickness of the bearing wall should be consistent.(2) there are two longitudinal walls inside the corridor, and the upper and lower layers are thick enough to adjust the depth of the rooms on both sides.(3) the thickness of the floor should be kept constant.(4) the basic unit of the structure must be open on one side, and the large span can be opened on both sides.(5) the arrangement should be avoided in the plane.

- Q: The periphery of the tunnel outline has been sealed with steel seal, and can be used as the external formwork when the concrete is poured. The 3 parts of the tunnel are divided into floor, side wall and roof. When pouring, the concrete can only be pumped in the tunnel, the outside of the tunnel is the Pearl River, and the construction can not be carried out outside the tunnel. The roof pouring, only from the bottom to the pump. Question: 1, the roof concrete pouring, how to discharge the air? How to tamper? 2, the tunnel width of 23 meters, you need to do the construction of the seam or after pouring it? Time is pressing, please reply as soon as possible. Good addition score. Thank you。 If you can't see the picture, click this link:

- Concrete construction technology of tunnel roof:Due to the main roof, the floor of a large amount of concrete pouring, consider the construction period and other factors, the site is equipped with 2 sets of automotive pump or HBT60 pump and 300m Phi pipe and a variety of accessories.

- Q: How to put the positioning point is based on what is mainly based on my novice, do not

- The next two large positioning along the side mode, re positioning of two small side mode along the point, then turn to check the center point and elevation, if not the positioning deviation is complete, then re adjust the positioning deviation! If you have time to measure the location of the site can be set up, then you do not nail this method, the five points directly to the elevation and mileage can be controlled for a long time

- Q: Would you please tell me the difference between the concrete and shotcrete in the tunnel?

- These two kinds of concrete construction method is actually the difference.Formwork concrete: after the formwork is good, the concrete is the concrete, such as the tunnel lining, the bridge pier and so on.

- Q: The tunnel has the super big pipe shed and the lead small conduit, is carries on the blasting excavation first or carries on the advance support first, has the anchor rod in the tunnel, this between the construction craft order is any

- Measuring and setting out the drill hole charge blasting, ventilation, smoke exhaust, water spraying and dust removing, the top of the vertical arch, the anchor rod and the reinforcing steel net, the spraying concrete operation enters the next cycle, and the first branch is stabilized and then the two lining is applied

- Q: What are the reasons for the two lining concrete lining of the tunnel?

- (3) the concrete pump tube, vibration rod and other mechanical repeated impact, workers trample or vibrator touch bar, caused by displacement and deformation of steel exposed.

- Q: I would like to know the safety awareness of the tunnel lining formwork trolley Prawns to help answer oh

- Second, check the obstacles before starting, the process of attention to observe at any timeWire, wind

- Q: Demolition of tunnel bearing formwork for several days

- The removal time of concrete wall and beam column pouring template is determined according to the strength of concrete, different situations: different removal time of concrete strength of the bottom die and the bracket removal should meet the following requirements:

- Q: In the tunnel construction, the water stop belt and the water stop strip are respectively used in what place, the construction joint and the subsidence seam many meters set a, above all has any function

- If you need to connect in the field, you can use the electric heating plate vulcanization bonding or cold bonding (rubber water stop) or welding (plastic water stop) method, such as user connection is difficult, I can send technical personnel on-site guidance.

- Q: In the process of tunnel construction, two kinds of formwork system should be adopted in the construction of the two lining concrete. Q: what is the template trolley?

- Tunnel two lining concrete pouring mould! Template trolley!

Send your message to us

building tunnel formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords