Automatic Hydraulic Tunnel Formwork

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

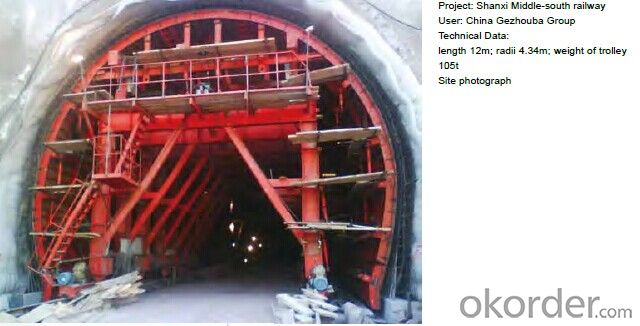

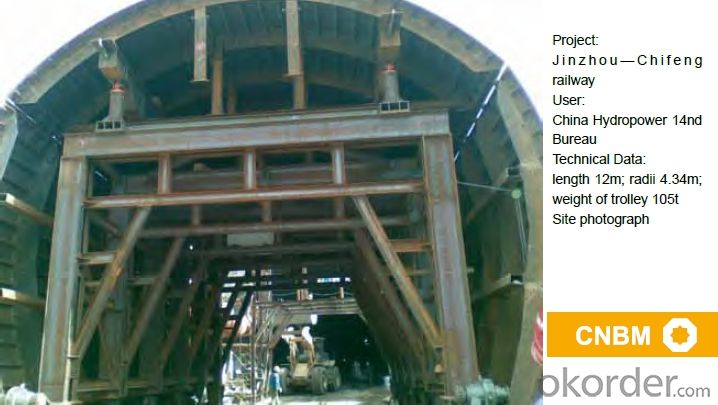

TUNNEL FORMWORK

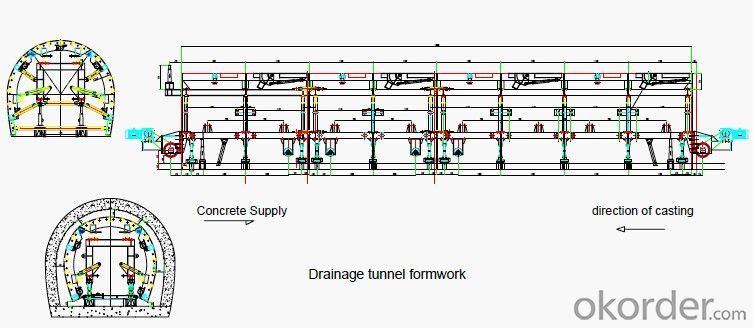

The automatic hydraulic tunnel formwork is the equipment to make

the concrete lining for the tunnel in one time.The empty gantry allows the

transport vehicles to pass. The motor gearbox is adopted to drive

the whole equipment, the formwork is fully hydraulic, with hydraulic

cylinder to prop & strip, and lock mechanically

◆ Good concreting quality

◆ High-speed of installation and removal of the form

◆ Easy operation and safety

- Q: 1 tunnel lighting design steps, 2 teacher said to design a template, is not to create a tunnel, and then according to the numerical calculation of what?

- Hope to help you. If the human eye to adapt to different levels of illumination, the need to go through three processes, namely, changes in the size of the pupil, nervous system adaptation, cone and rod cells of the photochemical adaptation of pigment.

- Q: What is the vault vault seal and dead seal please give a detailed drawing of the drawing bar do not know how to do?

- Directly in the template hole, make a steel plate bolt

- Q: How to fill in the tunnel template

- The template is firm and smooth, there is no error, such as leakage

- Q: How the arch of the tunnel concrete pouring up, how to support before pouring, using I-beam is directly support the earth?

- Small pipe or large, medium pipe shed is the advanced support for the broken rock area or into, out of the hole, of course, grouting, grouting without losing the significance of the implementation.

- Q: How to design the general layout of the tunnel construction organization design

- I need to contact you to provide a template..

- Q: What is the role of the grid steel frame and steel mesh in the power tunnel

- Advanced small pipe grouting small catheter with a diameter of 32-50mm steel pipe, the pipe tip and tube holes for special processing. The first row with drill drilling pipe. Row spacing is 30cm, fan shape, elevation of 5 degrees to about 8 degrees. The length is 2.25m, a single fluid grouting (cement) or double grout (cement water glass slurry). Adjust the grouting pressure according to the soil.

- Q: When the two lining of the tunnel is used as the lining concrete of the two, how to lay the trolley? Please kindly explain steps.

- The first measurement group with total station will be five points (template center, 2 large side mode along the point, 2 small side mode along the projection point) in lofting invert, with nails into the inverted arch concrete as a symbol, and note the nail surface elevation. The trolley positioning, the first to the two lining trolley running mileage, and positioning, positioning process will have been completed two off the top two tight lining lining, free end positioning first center point positioning control of elevation and with a plumb line (top surface elevation is equal to the length of the plumb line + if the mileage of two the center point of elevation can be lining)

- Q: What are the reasons for the two lining concrete lining of the tunnel?

- (1) the steel frame is put aside, there is no reinforcement pad or pad number is not enough, the position is not correct, resulting in the reinforcement close to the template and exposed.(2) the coarse aggregate size is greater than the reinforcement spacing, or the debris is placed in the steel frame, while the concrete leakage, forming a serious honeycomb and holes and exposing the reinforcement.

- Q: The arch and the arch of the tunnel

- Tunnel invert refers to the bottom of the tunnel (anti arch, so called inverted arch)

- Q: How many meters can be poured in the first floor of the 2 level of the surrounding rock of the railway tunnel?

- And these kinds of excavation methods need to determine the number of excavated meters according to the grade of surrounding rock. Tunnel invert and floor is completed after the initial support (that is, shotcrete, a layer of concrete, in the excavation of rock on some hard rock without vertical spray arch thin, weak surrounding rock shall be sprayed on the vertical arch thickness in this special project map will show) for pouring 2 reinforced concrete lining when left in general is 6~12 meters

Send your message to us

Automatic Hydraulic Tunnel Formwork

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords