Tunnel Steel Template with Easy Operation

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

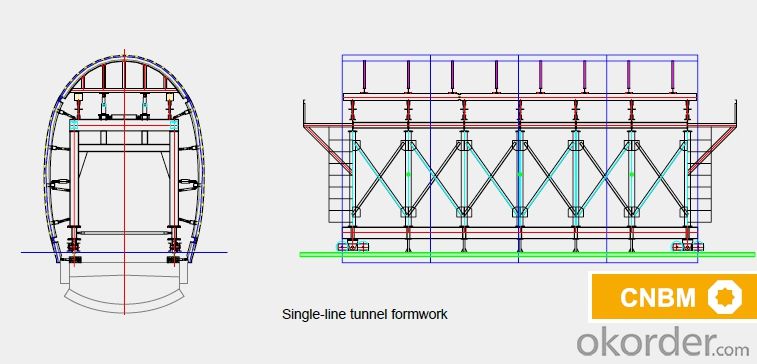

TUNNEL FORMWORK

The automatic hydraulic tunnel formwork is the equipment to make

the concrete lining for the tunnel in one time.The empty gantry allows the

transport vehicles to pass. The motor gearbox is adopted to drive

the whole equipment, the formwork is fully hydraulic, with hydraulic

cylinder to prop & strip, and lock mechanically

◆ Good concreting quality,fully hydraulic.With hydraulic

cylinder to prop & strip, and lock mechanically

◆ High-speed of installation and removal of the form

◆ Easy operation and safety.The empty gantry allows the

transport vehicles to pass.

- Q: I would like to ask the tunnel step method excavation, the height of each step is how to divide?

- On the circular arc heading cutting method, the excavation of each cyclicfootage and steel frame with same interval, after the excavation will be used in the initial support, the excavation behind the steps of 8~10m, after the excavation construction of initial support and invert, and then the middle rock pillar grouting reinforcement. (4) of excavation the surrounding rock and the surrounding rock in deep buried section IV and supporting: IV rock by step excavation method, step up the steps behind 8~10m, up and down the steps of primary support construction must follow with the excavation. Rock class take the whole section excavation method. (5) are the simple types of rock excavation self assembling drilling trolley, with dump truck shipment mucking loader. In order to ensure the safety and stability of tunnel construction in soft rock section, the construction must follow the "weak blasting, little disturbance, short excavation, strong support and frequent measurement, tight lining", in the application of The following measures shall be taken

- Q: The tunnel structure of plastic mould

- The tunnel model is a kind of tool form template which is used for pouring concrete wall and floor at the same time.Total tunnel mode tunnel mode and half tunnel mode two, the basic unit of the tunnel mode is a complete tunnel template, half tunnel is composed of a plurality of unit angle die, and then use the 2.5 tunnel mode to fight and become a complete tunnel mode.

- Q: How to fill in the tunnel template

- The template is firm and smooth, there is no error, such as leakage

- Q: Would you please tell me the difference between the concrete and shotcrete in the tunnel?

- Characteristics of shotcrete:(1) the sprayed concrete has the characteristics of rapid growth, strong bonding force, high density and good impermeability. It can better fill the gap between the rock blocks, increase the integrity of the surrounding rock, prevent the free surface weathering and loosening, and work together with the surrounding rock.(2) the construction of shotcrete will transfer, pouring and tamping a few processes into one, and do not need a template, so the construction of fast, simple.(3) sprayed concrete can play an important role as early as possible.(4) compared with the concrete, the physical and mechanical properties of sprayed concrete are improved.

- Q: Tunnel steel arch behind the steel mesh after a layer of fine iron wire mesh what effect is there?

- 5, the construction of the lining structure in the construction process of the power tunnel, the construction of the first lining structure is the eighteen word construction principle of the strong support principle. Construction of lining structure is the guarantee and foundation of tunnel construction safety.

- Q: What are the reasons for the two lining concrete lining of the tunnel?

- (1) the steel frame is put aside, there is no reinforcement pad or pad number is not enough, the position is not correct, resulting in the reinforcement close to the template and exposed.(2) the coarse aggregate size is greater than the reinforcement spacing, or the debris is placed in the steel frame, while the concrete leakage, forming a serious honeycomb and holes and exposing the reinforcement.

- Q: What is the simple calculation method of the tunnel excavation unit price

- Comprehensive unit price = labor cost + material equipment fee + mechanical + management fee + profit

- Q: Main diseases and prevention of tunnel

- Tunnel shotcretePhenomenon: the concrete spray layer and the rock surface is not bonded, concrete spray layer between the bond is not good.Cause analysis: the loose rock not clear spray surface; shotcreted rock debris is not scum washing or flushing thoroughly with wind pressure, water pressure; surface by spraying water, water, water concentration of untreated concrete spraying interval; before a layer of spray surface without wind, water washing scum. The air pressure is inconsistent with the spray distance.Preventive measures: remove the loose rock, clear surface by spraying of water, slag floating debris; water, concentrated water point of the surface by spraying with gouge, guide the drainage treatment of buried pipe; sprayed concrete before spray test, to determine the wind and spray distance coordination relationship between.

- Q: When the tunnel fight, there is no provision to fight how many meters left, only by one of the construction

- Fixed strip: the use of additional reinforcement fixation; special fixture fixed; the wire and the fixed template (Figure 2).

- Q: How many meters can be poured in the first floor of the 2 level of the surrounding rock of the railway tunnel?

- And these kinds of excavation methods need to determine the number of excavated meters according to the grade of surrounding rock. Tunnel invert and floor is completed after the initial support (that is, shotcrete, a layer of concrete, in the excavation of rock on some hard rock without vertical spray arch thin, weak surrounding rock shall be sprayed on the vertical arch thickness in this special project map will show) for pouring 2 reinforced concrete lining when left in general is 6~12 meters

Send your message to us

Tunnel Steel Template with Easy Operation

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches