Tunnel Steel Template with High-speed of Installation and Removal

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

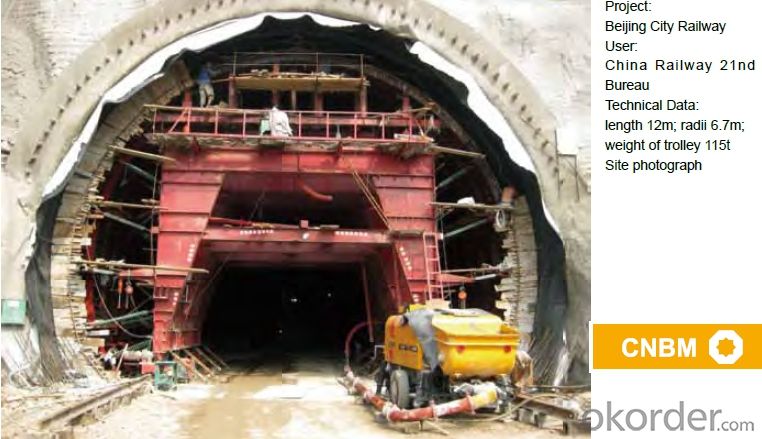

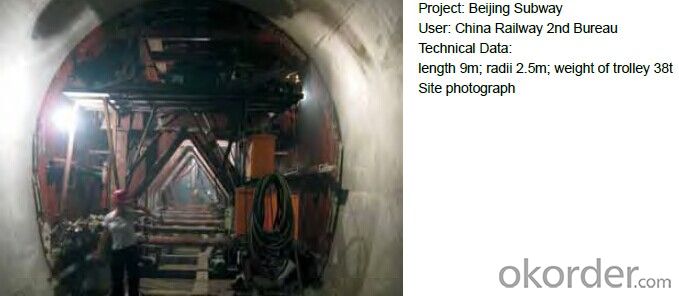

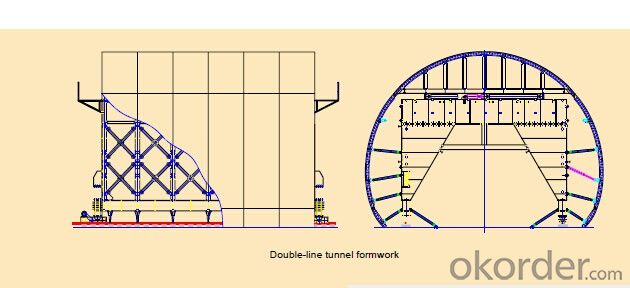

TUNNEL FORMWORK

The automatic hydraulic tunnel formwork is the equipment to make

the concrete lining for the tunnel in one time.The empty gantry allows the

transport vehicles to pass. The motor gearbox is adopted to drive

the whole equipment, the formwork is fully hydraulic, with hydraulic

cylinder to prop & strip, and lock mechanically

◆ Good concreting quality

◆ High-speed of installation and removal of the form

◆ Easy operation and safety

- Q: Ask, general highway tunnel measurement with the total station to measure which aspects? The more detailed the better

- The first instrument identification, according to the drawings issued by the tunnel portal design to determine, determine the portal after the slope portal to lofting, tunnel excavation and excavation contour checking (i.e. overexcavation measurement)

- Q: Loess tunnel construction quality control points

- The main points of concrete construction of tunnel invert:1) should advance concrete arch wall concrete construction of inverted arch arch and the construction should be removed before water, slag and other sundries, false

- Q: Highway bridge template needs, probably with the thickness of both the construction requirements can be met, and more cost-effective?

- According to the actual situation of your project

- Q: How the arch of the tunnel concrete pouring up, how to support before pouring, using I-beam is directly support the earth?

- The excavation of the tunnel face, slag, to the primary support system, first hit the bolt, then use steel or steel made of steel, installation support in tunnel contour, and then sprayed concrete (poor surrounding rock hanging steel mesh, then sprayed fiber concrete).

- Q: How to design the general layout of the tunnel construction organization design

- I need to contact you to provide a template..

- Q: Demolition of tunnel bearing formwork for several days

- With the temperature, the need for concrete strength of 100% to remove the template

- Q: A detailed method is introduced

- The construction methods and technical measures2.1 construction processTo measure the slope, slope protection, Boulder rolling, processing or drainage construction, earthwork excavation, slope protection, inverted arch and side wall foundation construction, liming cave mould, steel banding, liming mould, pouring concrete, concrete outside the health to release, waterproof layer construction, backfilling and protection engineering construction.2.2 construction methods1) Myongdong and a complete portal excavation, excavation with full width transverse dredging method once formed, the first slopes, put the line before the excavation, then drain.2) with earthwork excavating, the small rock blasting method, drill hole, millisecond electric detonator, mucking loaders, dump truck transport, blasting near the slopes, with smooth blasting, in order to ensure the stability of slope. Excavation from top to bottom, side of the construction side slope excavation and slope into the face of the protection works.3) the first tunnel excavation after 10 ~ 20m, and then open cut tunnel lining. When construction, pay attention to Myeongdong and at the joint of the dark hole, from the inside out.4, before entering the cave, complete all slope reinforcement and protection measures.

- Q: In the process of tunnel construction, two kinds of formwork system should be adopted in the construction of the two lining concrete. Q: what is the template trolley?

- Tunnel two lining concrete pouring mould! Template trolley!

- Q: Two tunnel lining reinforced concrete template to price behavior can be contracted

- There is two times of lining concrete pouring, the normal price is within 100 yuan, this is the pure artificial price, does not contain steel trolley and various materials two tunnel lining.

- Q: I would like to ask the high-speed rail tunnel invert small side wall and arch with the small side of the wall of the hanging formwork of what a good method?

- Die casting. Install the inverted L hanger on the side wall.

Send your message to us

Tunnel Steel Template with High-speed of Installation and Removal

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords