Galvanized Steel Stock Tank

Galvanized Steel Stock Tank Related Searches

Galvanized Steel Tank Stainless Steel Stock Tank Aluminum Stock Tank Aluminum Stock Tanks Large Aluminum Stock Tank Stock Tank Aluminum Galvanized Tube Steel Galvanized Steel Tube Galvanized Steel Trash Can Steel Galvanized Galvanized Steel Tub Stainless Steel Tank Galvanized Steel Storage Shed Aluminum Stock Tank Pool Galvanized Steel Pool Round Aluminum Stock Tank Galvanized Steel Paint Stainless Steel Tanks Stainless Steel Storage Tank Galvanized Steel Bucket Galvanized Stainless Steel Galvanized Steel Planter Box Galvanized Steel Tubs Galvanized Steel Roof Galvanized Steel Panel Aluminum Stock Tanks For Sale Galvanized Steel Planter Painted Galvanized Steel Galvanized Steel Fence Galvanized Steel PanelsGalvanized Steel Stock Tank Supplier & Manufacturer from China

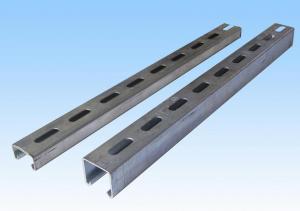

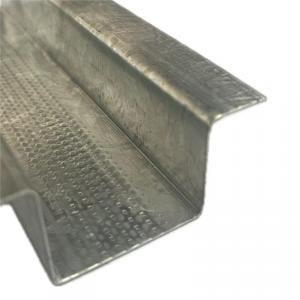

Galvanized Steel Stock Tanks are robust and durable containers designed for various purposes, including water storage, livestock watering, and industrial applications. These tanks are made from high-quality galvanized steel, ensuring longevity and resistance to corrosion. They are an ideal solution for those seeking a reliable and cost-effective storage option.Galvanized Steel Stock Tanks are widely used in agricultural settings, providing a convenient and efficient way to supply water to livestock. They are also utilized in construction and industrial sectors for storing and transporting liquids. These tanks are available in various sizes and shapes to cater to different requirements and can be easily installed and maintained.

Okorder.com is a reputable wholesale supplier of Galvanized Steel Stock Tanks, boasting a vast inventory to meet the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com offers competitive prices and excellent service, making it a preferred choice for those in search of reliable and affordable Galvanized Steel Stock Tanks.

Hot Products