Automatic Hydraulic Tunnel Steel Template

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

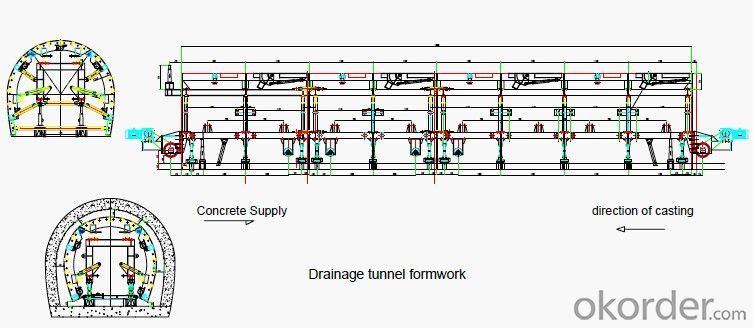

TUNNEL FORMWORK

The automatic hydraulic tunnel formwork is the equipment to make

the concrete lining for the tunnel in one time.The empty gantry allows the

transport vehicles to pass. The motor gearbox is adopted to drive

the whole equipment, the formwork is fully hydraulic, with hydraulic

cylinder to prop & strip, and lock mechanically

◆ Good concreting quality

◆ High-speed of installation and removal of the form

◆ Easy operation and safety

- Q: 1 tunnel lighting design steps, 2 teacher said to design a template, is not to create a tunnel, and then according to the numerical calculation of what?

- Hope to help you. If the human eye to adapt to different levels of illumination, the need to go through three processes, namely, changes in the size of the pupil, nervous system adaptation, cone and rod cells of the photochemical adaptation of pigment.

- Q: Highway bridge template needs, probably with the thickness of both the construction requirements can be met, and more cost-effective?

- Hello, highways, bridges, tunnels, dams, railways and other projects, are generally used in bridge plate 12/15/18MM specifications

- Q: What is the vault vault seal and dead seal please give a detailed drawing of the drawing bar do not know how to do?

- The arch support is an adjustable template or a small template

- Q: The tunnel lining is wood, how should support?

- Small pipe or large, medium pipe shed is the advanced support for the broken rock area or into, out of the hole, of course, grouting, grouting without losing the significance of the implementation.

- Q: How the arch of the tunnel concrete pouring up, how to support before pouring, using I-beam is directly support the earth?

- The excavation of the tunnel face, slag, to the primary support system, first hit the bolt, then use steel or steel made of steel, installation support in tunnel contour, and then sprayed concrete (poor surrounding rock hanging steel mesh, then sprayed fiber concrete).

- Q: What is the role of the grid steel frame and steel mesh in the power tunnel

- Function as follows:1, the construction of the shaft excavation of the power tunnel shaft structure is a permanent structure, the construction of the shaft using shotcrete + net structure steel frame + steel mesh support + waterproof film + cast-in-place reinforced concrete lining method.

- Q: What is the concrete construction of the tunnel invert

- As the name implies, concrete is the concrete that needs to be supportedv

- Q: What is the first project of tunnel constructionNow to do some of the tunnel program, you need to be the first to list out, a total of what? I know that the first branch, two lining, inverted arch, tunnel, pavement these

- Summary of construction of the first two tunnel lining

- Q: When the tunnel fight, there is no provision to fight how many meters left, only by one of the construction

- Fixed strip: the use of additional reinforcement fixation; special fixture fixed; the wire and the fixed template (Figure 2).

- Q: 12 meters of the tunnel car, under normal circumstances, one of the two months to be able to cast a few models?

- Seven hours after the maintenance of formwork, pouring a every day is no problem, that is to say a month to about fifteen die casting.

Send your message to us

Automatic Hydraulic Tunnel Steel Template

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords