Single-side Bracket-formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

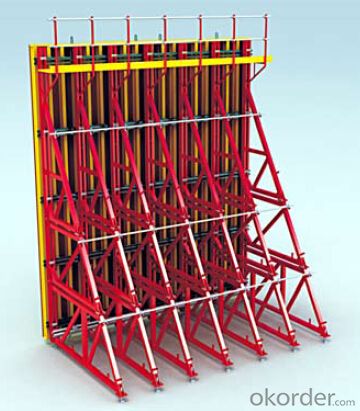

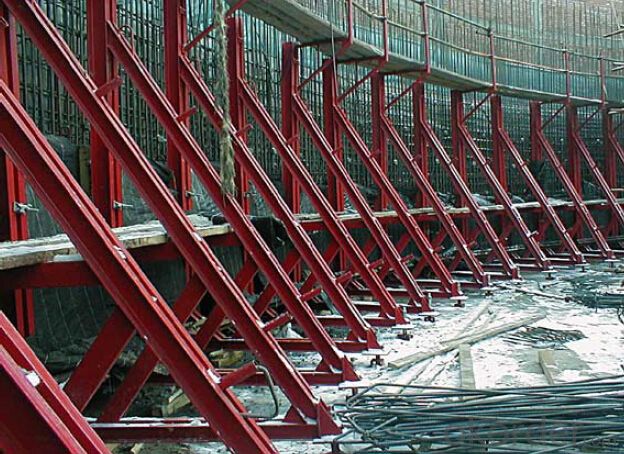

Single-side Bracket:

During single-sided concreting, the concrete pressure is transferred into the sub-structure by

means of the single-side bracket.

Characteristics:

◆ For concrete heights up to 8.0m and a fresh concrete pressure up to a maximum of 60KN/m2.

◆ Good standard performance and versatility.

◆ Fast element coupling, all units can be quickly connected.

◆ The finished wall is excellent and absolutely waterproof.

◆ Optimized sizes for transportation.

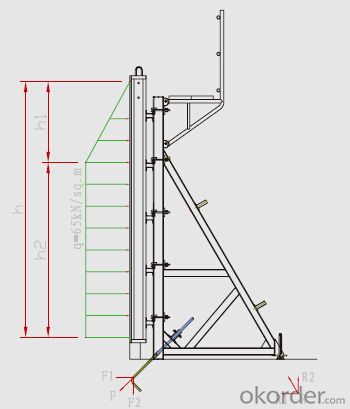

Design Principle:

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by

the anchor system and the regulator system.

The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2

can resist the rising force. R can not only bear the gravity force of the bracket, but also the side

pressure of the concrete. This stress system is simple, reasonable and also with convenience and

high safety.

- Q: 1 tunnel lighting design steps, 2 teacher said to design a template, is not to create a tunnel, and then according to the numerical calculation of what?

- Hope to help you. If the human eye to adapt to different levels of illumination, the need to go through three processes, namely, changes in the size of the pupil, nervous system adaptation, cone and rod cells of the photochemical adaptation of pigment.

- Q: The tunnel lining is wood, how should support?

- The excavation of the tunnel face, slag, to the primary support system, first hit the bolt, then use steel or steel made of steel, installation support in tunnel contour, and then sprayed concrete (poor surrounding rock hanging steel mesh, then sprayed fiber concrete).

- Q: How to design the general layout of the tunnel construction organization design

- I need to contact you to provide a template..

- Q: Who can give me detailed tunnel construction process

- In addition, after blasting excavation contour line must be used with artificial picks excavation, fill hole hole blasting is prohibited, should use the diamond, completes the construction of temporary drainage hole, the pump discharge hole, quartz, mica schist will accelerate the loss of self stability in water immersion, and will accelerate the development of the formation of rock joints, if the groundwater pressure too much damage to increase support.

- Q: Main diseases and prevention of tunnel

- Insufficient anchor tensionPhenomenon: anchor installation is not strong, pulling force is not enough.The reason analysis: anchor length is not enough; mortar grouting is not full; mortar wrapped anchor thickness is not enough or not at all; holes in the debris is not clean; the depth of the hole with the length of the bolt is not matching.Preventive measures: the hole diameter should be matched with the bolt diameter; strictly according to design deep hole drilling; grouting pressure and wind pressure water rinse perforations; bolt rust, straightening, ensure the bolt and hole center line on the same line of installation; the hole from the bottom of the hole, uniform and continuous. Midway not interrupt; using earlystrong medicine package bolt, the bolt diameter should be treated with perforation diameter matching.

- Q: A detailed method is introduced

- The construction methods and technical measures2.1 construction processTo measure the slope, slope protection, Boulder rolling, processing or drainage construction, earthwork excavation, slope protection, inverted arch and side wall foundation construction, liming cave mould, steel banding, liming mould, pouring concrete, concrete outside the health to release, waterproof layer construction, backfilling and protection engineering construction.2.2 construction methods1) Myongdong and a complete portal excavation, excavation with full width transverse dredging method once formed, the first slopes, put the line before the excavation, then drain.2) with earthwork excavating, the small rock blasting method, drill hole, millisecond electric detonator, mucking loaders, dump truck transport, blasting near the slopes, with smooth blasting, in order to ensure the stability of slope. Excavation from top to bottom, side of the construction side slope excavation and slope into the face of the protection works.3) the first tunnel excavation after 10 ~ 20m, and then open cut tunnel lining. When construction, pay attention to Myeongdong and at the joint of the dark hole, from the inside out.4, before entering the cave, complete all slope reinforcement and protection measures.

- Q: What is the first project of tunnel constructionNow to do some of the tunnel program, you need to be the first to list out, a total of what? I know that the first branch, two lining, inverted arch, tunnel, pavement these

- The first project of concrete lining of this section as I bid the tunnel project, on the next two plays a role model leading lining construction, so the various factors must be considered in detail, before the construction plan, reasonable arrangement, strict control of construction process, construction timely summary, finally reached the first the United States, the project entity information is true and complete, the project finished good target

- Q: When the tunnel fight, there is no provision to fight how many meters left, only by one of the construction

- Fixed strip: the use of additional reinforcement fixation; special fixture fixed; the wire and the fixed template (Figure 2).

- Q: There are no recycling tunnel templates

- Tunnel template, as far as I understand, is the tunnel two lining template

- Q: How many meters can be poured in the first floor of the 2 level of the surrounding rock of the railway tunnel?

- 6 excavation methods of tunnel1, full section method2 step method3, three steps of the 7 step excavation method4, septal wall method (CD method)5, the intersection of the next door method (CRD method)6, double side drift method

Send your message to us

Single-side Bracket-formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords