Single-side bracket formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

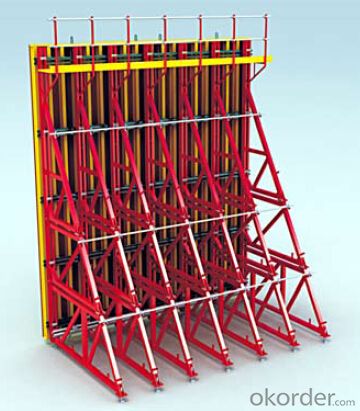

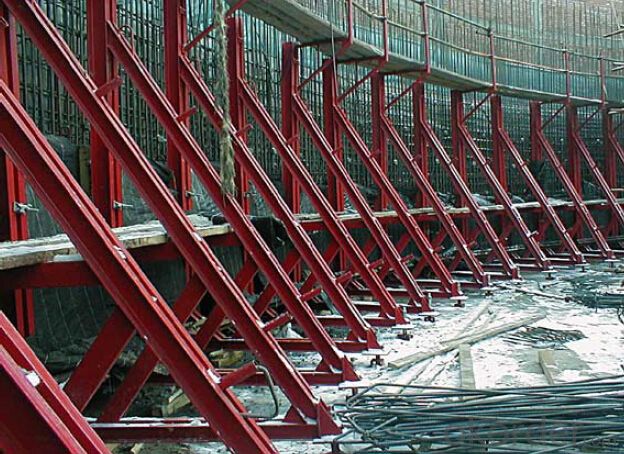

Single-side Bracket:

During single-sided concreting, the concrete pressure is transferred into the sub-structure by

means of the single-side bracket.

Characteristics:

◆ For concrete heights up to 8.0m and a fresh concrete pressure up to a maximum of 60KN/m2.

◆ Good standard performance and versatility.

◆ Fast element coupling, all units can be quickly connected.

◆ The finished wall is excellent and absolutely waterproof.

◆ Optimized sizes for transportation.

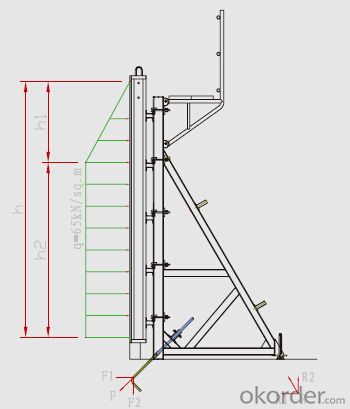

Design Principle:

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by

the anchor system and the regulator system.

The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2

can resist the rising force. R can not only bear the gravity force of the bracket, but also the side

pressure of the concrete. This stress system is simple, reasonable and also with convenience and

high safety.

- Q: I would like to ask the tunnel step method excavation, the height of each step is how to divide?

- The side ditch construction using composite steel formwork. (1) the temporary facilities of tunnel construction plan layout: in the single ended due to tunnel entrance, temporary facilities of tunnel construction in tunnel exit to the right. The layout for the layout of wind mechanical equipment in the right side of the roadbed export based on the terrain conditions, reservoir located in the left side from the position of about 80m. In the mechanical approach immediately after the entrance of earth excavation construction, roof slope and drainage ditches slope anchor slope reinforcement, well hole digging for. (2): the excavation and reinforcement the mechanical construction, according to the construction method of Subgrade Earthwork excavation, dig to the rock when, in order to minimize the disturbance of the entrance slope and subgrade slope, must adopt the method of weak blasting and presplitting blasting for excavation. The entrance slope using hang net shotcrete reinforcement, to facilitate the safety hole (3). The excavation and support of the shallow section of the surrounding rock of the cave: the construction method adopts the step method, and the advanced grouting bolt is adopted on the stage

- Q: The tunnel structure of plastic mould

- In the use of the whole tunnel mode is not as flexible as semi tunnel mode, the lifting equipment requirements are higher, it is gradually being semi tunnelMode substitution.

- Q: Highway bridge template needs, probably with the thickness of both the construction requirements can be met, and more cost-effective?

- Hello, highways, bridges, tunnels, dams, railways and other projects, are generally used in bridge plate 12/15/18MM specifications

- Q: Would you please tell me the difference between the concrete and shotcrete in the tunnel?

- Jet coagulation: the construction method of spraying fine concrete with spray gun. It is often used to fill the lining of tunnel lining, wall, ceiling and other structures.

- Q: Design of lining concrete is C30, what should be used in the construction of concrete arch cushion concrete?

- The thickness of the cushion should not be less than 70mm, and the concrete strength grade should not be less than C10;

- Q: Demolition of tunnel bearing formwork for several days

- The removal time of concrete wall and beam column pouring template is determined according to the strength of concrete, different situations: different removal time of concrete strength of the bottom die and the bracket removal should meet the following requirements:

- Q: Main diseases and prevention of tunnel

- Tunnel shotcretePhenomenon: the concrete spray layer and the rock surface is not bonded, concrete spray layer between the bond is not good.Cause analysis: the loose rock not clear spray surface; shotcreted rock debris is not scum washing or flushing thoroughly with wind pressure, water pressure; surface by spraying water, water, water concentration of untreated concrete spraying interval; before a layer of spray surface without wind, water washing scum. The air pressure is inconsistent with the spray distance.Preventive measures: remove the loose rock, clear surface by spraying of water, slag floating debris; water, concentrated water point of the surface by spraying with gouge, guide the drainage treatment of buried pipe; sprayed concrete before spray test, to determine the wind and spray distance coordination relationship between.

- Q: Two tunnel lining reinforced concrete template to price behavior can be contracted

- This problem should belong to the industry confidential!If the two lining of the tunnel is pure manual, the normal price is between 800 and 650,

- Q: When the tunnel fight, there is no provision to fight how many meters left, only by one of the construction

- Fixed strip: the use of additional reinforcement fixation; special fixture fixed; the wire and the fixed template (Figure 2).

- Q: How many meters can be poured in the first floor of the 2 level of the surrounding rock of the railway tunnel?

- And these kinds of excavation methods need to determine the number of excavated meters according to the grade of surrounding rock. Tunnel invert and floor is completed after the initial support (that is, shotcrete, a layer of concrete, in the excavation of rock on some hard rock without vertical spray arch thin, weak surrounding rock shall be sprayed on the vertical arch thickness in this special project map will show) for pouring 2 reinforced concrete lining when left in general is 6~12 meters

Send your message to us

Single-side bracket formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords