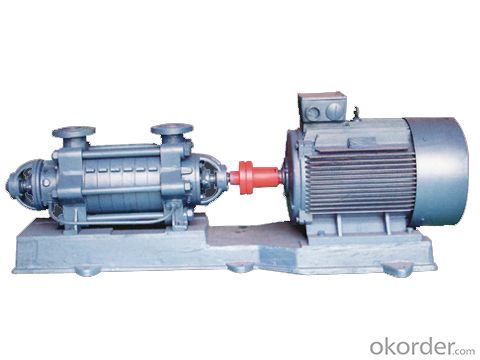

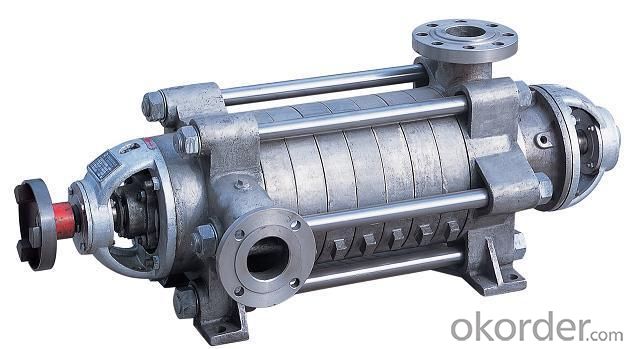

D series Horizontal Multistage Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview of D series Horizontal Multistage Centrifugal Pump

Our horizontal multistage centrifugal pump can be applied for transporting clear water or liquid with physicochemical property similar to that of the clear water. There shall be no solid particle, abrasive material or suspended solid containing in the liquid.

Particularly, this multistage centrifugal pump can be used for delivering hot water, oil corrosive liquid or medium containing abrasive material through special employment of material, sealing mode, or cooling system.

Application of D series Horizontal Multistage Centrifugal Pump

Municipal engineering ,Wastewater treatment ,constructional engineering

Agricultural irrigation , transfer water ,etc.

High-rise buildings water supply and drainage, and for fire working

Factory and mining for distance water supply and drainage

Circulation water supply for production process

Cooling systems of air-conditioning in hotels

Domestic water supply

Range of Parameters of D series Horizontal Multistage Centrifugal Pump

horizontal multistage dewatering centrifugal pump

Working Principle: Centrifugal

Main applications: mine coal water,chemical water

Driver: Electric Motor or Diesel Engine

Max Liquid Temperature: 105°C

Type of connection: Flange

Casing Material: cast steel, stainless steel

Impeller Material: cast steel, stainless steel

Seal: mechanical seal

Flow Range: 2~650m3/h

Head: 84~850m

Speed: 1450rpm/2900rpm

FAQ

Q: Is it really necessary to fit a bleed valve for the boxes?

A: It is always best to have a bleed valve as the gas produced by the fermenting sewage is potentially hazardous.

Q: If I increase the power of the motor, must I also increase the power of the inverter?

A: You must select the size of converter that allows maximum absorption of the electric motor.

Q: Do you have pumps with grinders?

A: Yes, the WQ models.

Q: How long is your warranty?

A: Unless otherwise expressly authorized in writing, by specifying a longer period or different conditions, CNBM states that, for a period of twelve (12) months from delivery date, all Products supplied are free from defects in materials and workmanship, and conform to the applicable specifications. Either the delivery documentation or the invoice must be provided to prove delivery date. In absence of such documents, the production date appearing on the product label may suffice.

- Q: Looking for a pro's advice here. My Corolla has developed a strange noise over the past few cold weeks (Highs of 10 degrees max, well below zero at night). The sound would best be described as a cricket-type rythmic chirp noticable during acceleration. I don't believe it's a belt because it comes and goes though it has steadily gotten louder. I vaguely remember this sound being related to a bad water pump I had a few years ago. Do you think this could be the same thing? Three years for a water pump? And do water pumps tend to go out more frequently in the cold weather? Thanks!!!

- First, you need to remove alternator belt and see if the noise disappear. then remove the AC (compressor belt) and notice if the noise disappear last , remove the power steering belt and see if the noise disappear IF NONE OF THESE STEPS HELP TO DETERMINE THE NOISE THEN YOU MAY HAVE TENSIONER TIMING BELT OR IDLER TIMING BELT OR WATER PUMP IS MAKING NOISE.

- Q: I'm just wondering where I should buy my new water pump for my 2.2 cavalier? Auto zone, carquest, checker? Does it matter which one?Thanks

- It does make a difference. Autozone and the other discount places carry cheap poorly made items. Go to NAPA.

- Q: was putting a water pump on, and i tight too much on 2 bolts, and they broke. is it anyway to fix it ?? is it going to cost alot in labor ??

- Well if the bolts are sticking out of the engine enough you can try screw extractors you can buy a set at your local store hammer that on then use a wrench or socket Extension to remove it. When you install the new bolts use a little anti-seeze and use a torque wrench.

- Q: 2005 pontiac grand prix 3.8 v6There is a scratching type of noise when i start the car. Looked under the hood and it seemed to be coming from the serpentine belt.Took the belt off and and checked the pulleys for any play and turned out the water pump pulley wobbles back and forth too much. Replaced the belt with a new one and want to replace the pulley. It does not seem to have a loose screw so i'm wondering if i can take the pulley itself off and replace it, or would i have to replace the pump too? Still makes the noise with new belt and you can see the pulley wobble a bit when the car is running.

- you have to replace the pump ! it,s not the pulley that,s wobbling, it,s the bearing in the water pump that,s bad and you can,t replace the bearing !

- Q: Pump house should be equipped with those equipment and valves

- The pump room generally the main equipments used are: pipe, water pump, water pump control box, inlet valve, outlet valve, check valve, pressure gauge, water valve and a water tank, according to the specific design of the pump room to you, just above the pipe segment.

- Q: What is a 1 inch water pump?

- A pump with a diameter of 1 inches.

- Q: So when you exercise, is the amount of salts and water pumped out in the loop of henle reduced, if so why????

- Salt impacts the osmotic interest of a cellular. this implies that once it somewhat is modern-day in severe concentrations interior the cellular, water strikes into the cellular with the aid of osmosis. This extra water getting into the cellular could reason the cellular to rupture. interior the kidneys an identical mechanism applies. whilst the concentration of NaCl is severe interior the tubules extra water is retained interior the physique. besides the incontrovertible fact that, whilst the concentration of NaCl is low interior the Kidney tubules much less water is retained by utilising the physique.

- Q: Im half way through replacing my water pump and im stuck...the power steering pump pully blocks access to the final bolt that needs to be removed so the water pump can be removed so i can replace the water pump... any hints on how to get to the bolt so i dont disassemble something i dont need to?

- 2003 Impala Water Pump

- Q: can bad water pump make car overheat?

- Yes because it what allows the engine coolant to flow to keep the car on the right temperature.

- Q: I need a new timing belt and I'm getting that done soon, but my mechanic says that water pumps are usually replaced along with the timing belt at the same time. Does it really need replaced?

- i have a nissan pickup and i changed the timing set at 88k miles and opted not to change the water pump. bad move, since my water pump was driven from my timing chain. the new timing set put more stress on my water pump than the old slacked one did, and about 6000 miles later the seal on the inner water pump shaft started leaking and filled my oil with water. it took about a week for the mechanic to diagnose the problem and cost me 550 dollars in labor and parts. should've changed the water pump when i changed the timing set. could've saved 300 dollars in the long run. now if you have a belt driven water pump, like that in a chevy truck then it should be fine.

Send your message to us

D series Horizontal Multistage Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords