Anti-arch Adjustment Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

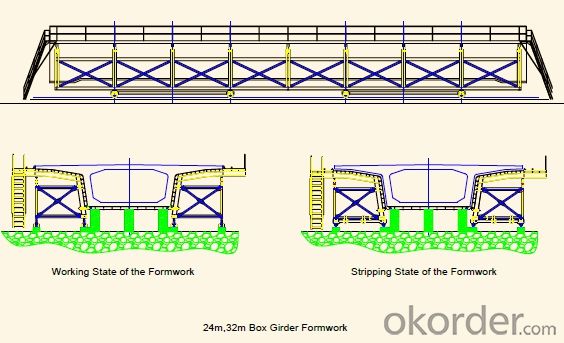

BOX GIRDER

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: The calculation of formwork engineering quantity of ground beam needs to calculate the bottom of beam

- The ground beam (patand) agreement is commonly known as the foundation beam, which has the characteristics of closed, and the structure of the column into a seismic system,

- Q: Remove the larger span of the beam pillar template why should be removed from the middle to the two ends

- The maximum bending moment in the middle of the beam is removed from the middle of the support, the stress is concentrated on the two supporting end, and the final force form is the same as the reinforcement of the beam, and the bending and the excessive shear force are not generated

- Q: Why is Changshi beam, but also computing to the side or side column beam?How to deduct the overlap area between beam and plate, column and wall, wall and wall

- Cross beam and beam cross section is not a template overlap

- Q: Which part of the middle beam and side beam in the T beam template? Thank you

- The use of T beam highway bridge generally 5 pieces of beam for the span of 1, which is the outermost of the two to become [edge beam]

- Q: According to the experience, who knows the construction area and template, plate, column, beam volume, steel, etc.!

- Shear wall structure (such as small high-rise, high-rise) per square meter area of the content of the building: the template to expand the area of about 3.3 to 3.6 square meters,About 0.5 cubic meters of concrete, steel bar about 60 to 75Kg.

- Q: For example, a beam 200*400, length 5000Plate thickness 1005000*5000The area of the template is1, (0.2+0.3*2) *5+5*52, 0.3*2*5+5*5Which is right

- The beam of the template is to calculate the beam height (minus the plate thickness of the part) * net long *2 surface. The bottom die has been calculated in the bottom plate.Louzhu certainly not familiar with the construction site, as long as the scene to see how the template is placed.

- Q: The bottom of the board 12.24*7.44 why not *2 floor 12.24 of the two of the 7.44 also have the plate side mode *2 is * of the two or both

- Figure is too small, the eyes are looking at flowers.1, floor 12.24*7.44 is the bottom of the whole plate (including the bottom of the beam), and then subtract the column area. Board only need to calculate the bottom and side die on the line, do not use *2.

- Q: For example, the 0.14 long girder thick 400x600 26 how to calculate the amount of engineering template

- According to the calculation of the expansion area, the height of support according to the bottom elevation

- Q: First of all, what are the construction of the structure of the template, such as walls, columns, beams and ladders, which is the structure of the first installation of the template after the installation of steel? Ten

- Who told you that?. Shear wall, column is the first binding steel, and then close the template, if the two sides of the shear wall formwork and the death of the death of the column template, but also how to bind and connect steel

- Q: 10-3 degrees of weather, cast in situ floor and girder formwork can be demolished a few days? 25 days enough? There's a wall on the beam.

- For the cantilever member of concrete structure engineering, the concrete strength can reach to 100% of the standard value of concrete cube compressive strength.

Send your message to us

Anti-arch Adjustment Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords