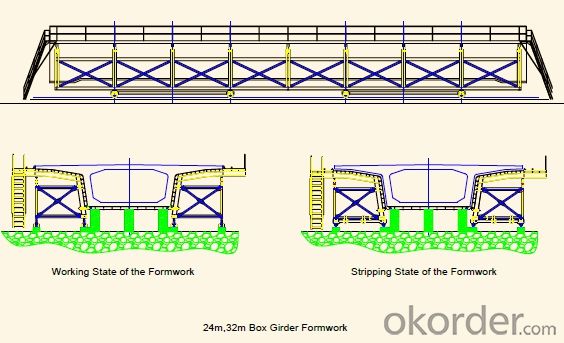

Wholely Assembled Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

BOX GIRDER

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: How to calculate the length of the beam, beam template area

- This is the case: (7800-600) * (800*2+400) forgot, 800 also minus plate thickness

- Q: What is the wire mesh in front of the foundation beam

- Wood can be used, but the surface is relatively smooth, after pouring, the bond will be worse; in this way, the construction is more convenient, leaving the rough concrete surface.

- Q: When the main beam and secondary beam connection, calculate the area of the template is good, there is no simple method

- It would take the high beam length reduced thickness, and by 2, the last plus beam bottom

- Q: The section size of the beam is 200 x 400 the size of the board is 4500 x 4000 plate thickness of the formula for 120 - a rookie

- Building template:Building template is a temporary support structure is made according to the design requirements, the concrete structure components, according to the position and size of the provisions of forming, maintaining its correct position, external loads and under construction template gravity and acting on the. The purpose of template engineering is to ensure the quality of concrete engineering and construction safety, speed up the construction progress and reduce the cost of the project.This paper introduces the construction formwork structure of cast-in-place concrete structure construction, which is mainly composed of three parts: the panel, the supporting structure and the connecting parts. The panel is in direct contact with the bearing plates of concrete; supporting structure is a temporary structure supporting panel, concrete and construction load, ensure the construction template are firmly combined, do not deform and damage; the connecting piece is connected to the panel and the supporting parts of the whole structure.Building formwork is the concrete pouring forming shell and support, according to the nature of the material can be divided into building template, building wood plywood, covered with plastic board, multilayer board, double-sided adhesive, double-sided coated building template. According to the construction process, the construction formwork can be divided into the cast in place concrete formwork, the pre assembled template, the large formwork, the jump formwork and so on.

- Q: Beam column plate template how to calculate the need to deduct what part?

- Plate under the formwork and then if there is a beam under the board, then the beam and the plate side of the area to cut off the sideDo not understand the words can continue to ask

- Q: How to calculate the intersection of rectangular column and beam

- Beam:(1): the length of beam to column connection, the length of the beam to column side; girder transfer, beam to beam side. The beam length at the door (window) wide hole net length calculation. According to the center line, wall beam wall is calculated according to the net line.(2) the area of the beam connecting part is not deducted, and the area of the beam head is not increased(3) the area of the beam pad is incorporated into the beam

- Q: For example, the 0.14 long girder thick 400x600 26 how to calculate the amount of engineering template

- Calculating the area of template according to the contact surface

- Q: How to control the elevation of the beam bottom and the axis position

- The axis is controlled by hanging the ball down to the lower floor axis and the axis control line.

- Q: What is the demolition order of the construction template

- Template removal sequence:General is the first non load bearing template, but bearing template; the first side plate, the back plate. Follow the line after the demolition, the demolition of non weight-bearing parts, the demolition of the load-bearing parts and the principle of top-down,

- Q: The main floor beam template installation should pay attention to what?

- See the technical disclosure records, the main operating process1) according to the axis of the 500mm line and the horizontal elevation control line on the concrete cylinder.

Send your message to us

Wholely Assembled Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords