Highly Efficient &Easy Installation Wholely Assembled Box Girder Formwork

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

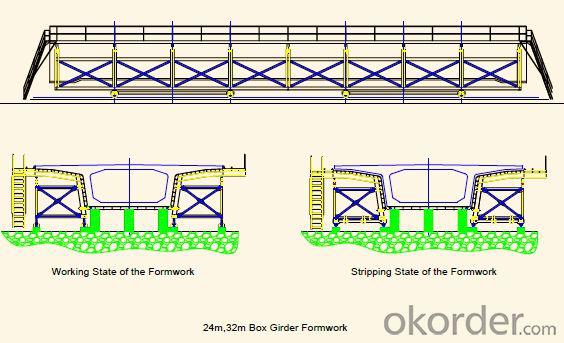

Wholely Assembled Box Girder

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: How to calculate the length of the beam, beam template area

- This is the case: (7800-600) * (800*2+400) forgot, 800 also minus plate thickness

- Q: Remove the larger span of the beam pillar template why should be removed from the middle to the two ends

- When the formwork of the beam is not removed, the load of the beam is evenly distributed. If the two ends of the span from the demolition of the words, the load is borne by the beam at both ends of the column and the template in the cross, when the removal of the template in the cross, the beam is likely to produce cracks and damage. Only from the cross to the ends of the removal, the load is evenly distributed to the ends of the column, the beam will not be destroyed.

- Q: What is the foundation beam template

- The foundation beam without the beam side template of this code, the foundation beam is not calculated at the bottom of the template, select the basis of the beam on the beam directly to the template area.

- Q: I only see the span is greater than 4M of the beam arch height is 1/1000~3/1000, if that is 5m, 8m, 12M, 16m and even assuming 20m, the supply is only 1/1000~3/1000????

- 1, in order to prevent the concrete weight and construction load to other beam and plate template pendulous; if there is no design provisions, the arch height is the length of the cross beam and plate 1/1000~3/1000; (general wood template for 1.5/1000~3/1000; steel template for 1.5/1000~2/1000.)

- Q: The bottom of the board 12.24*7.44 why not *2 floor 12.24 of the two of the 7.44 also have the plate side mode *2 is * of the two or both

- Figure is too small, the eyes are looking at flowers.1, floor 12.24*7.44 is the bottom of the whole plate (including the bottom of the beam), and then subtract the column area. Board only need to calculate the bottom and side die on the line, do not use *2.

- Q: The area of the beam template = (both sides of the high and low beam) * beam lengthWhat do you mean by the two words in the brackets?

- Calculation of contact area between concrete and formworkPillar: circumference multiplied by the column height, from the pile or board surface of a first floor surface, non beam plate count to the bottom of the column cap

- Q: Beam column plate template how to calculate the need to deduct what part?

- The second is to calculate the template of the beam to calculate the template of the beam with the section length multiplied by the length of the unit is M2Finally the board notice when calculate the template template amount is peripheral template must take and post together part to deduct the intersection with beam part to be deducted

- Q: How to do the foundation beam template

- The main construction method by a formwork one-time-concreting organization construction, wall, column and beam plates without construction joints, each layer of wall, column, beam plate model, a branch of Qi, while pouring concrete.

- Q: When there is a beam plate template, the beam can not be added to the template?

- SureBeam template, template, template based beam section is different

- Q: First of all, what are the construction of the structure of the template, such as walls, columns, beams and ladders, which is the structure of the first installation of the template after the installation of steel? Ten

- On the contrary, the beam plate is the first template, tied after the reinforcement, because the beam plate is flat, the first binding steel, do you want to let the first suspension? That's not going to collapse

Send your message to us

Highly Efficient &Easy Installation Wholely Assembled Box Girder Formwork

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords