Assembly Precision Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

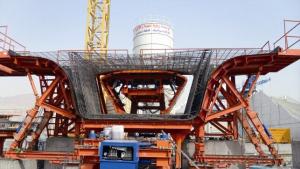

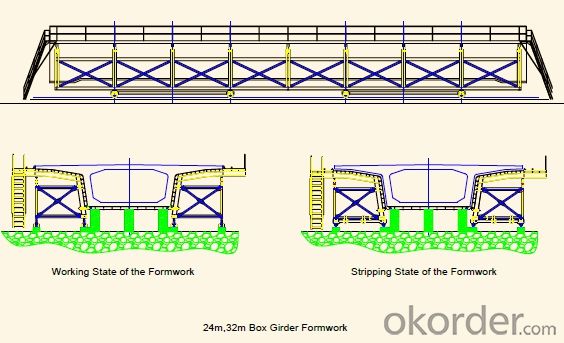

BOX GIRDER

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: How to put the beam formwork in concrete structure

- When the carpenter die down from the ceiling! To determine! But you need to check it regularly! Not everyone does it by the rules!

- Q: I only see the span is greater than 4M of the beam arch height is 1/1000~3/1000, if that is 5m, 8m, 12M, 16m and even assuming 20m, the supply is only 1/1000~3/1000????

- 1, in order to prevent the concrete weight and construction load to other beam and plate template pendulous; if there is no design provisions, the arch height is the length of the cross beam and plate 1/1000~3/1000; (general wood template for 1.5/1000~3/1000; steel template for 1.5/1000~2/1000.)

- Q: How to do irrigation formwork

- Pro, beam section is marked on the drawings, the beam is 200*500.

- Q: What is the meaning of the steel beam overhead on the top of the beam formwork

- So in the form of the frame up binding, binding with a crane to lift the steel beam, the following overhead with the wood out of the beam of steel on the template

- Q: Calculate the beam template when you want to reduce the thickness of the plate

- Now the general calculation of the template area is to contact the concrete surface is positive, of course, the thickness of the template to be deducted.

- Q: The bottom of the board 12.24*7.44 why not *2 floor 12.24 of the two of the 7.44 also have the plate side mode *2 is * of the two or both

- Figure is too small, the eyes are looking at flowers.1, floor 12.24*7.44 is the bottom of the whole plate (including the bottom of the beam), and then subtract the column area. Board only need to calculate the bottom and side die on the line, do not use *2.

- Q: More than the number of square cross-section of the beam high formwork

- According to the "dangerous method" sub project safety management of the construction quality of [2009]87, the height of more than 5m, the total construction loads greater than 10kN/m2, or the template support system concentrated line load greater than 15kN/m to prepare special construction scheme

- Q: Beam column plate template how to calculate the need to deduct what part?

- Plate under the formwork and then if there is a beam under the board, then the beam and the plate side of the area to cut off the sideDo not understand the words can continue to ask

- Q: A set of 50 m T beam steel template weight

- So as to complete the precast beam and slab

- Q: How to control the elevation of the beam bottom and the axis position

- The axis is controlled by hanging the ball down to the lower floor axis and the axis control line.

Send your message to us

Assembly Precision Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords