Wholely Assembled Box Girder Template Made in China with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wholely Assembled Box Girder

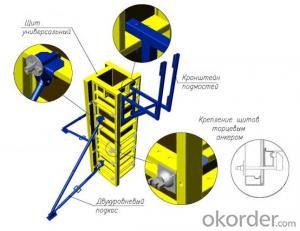

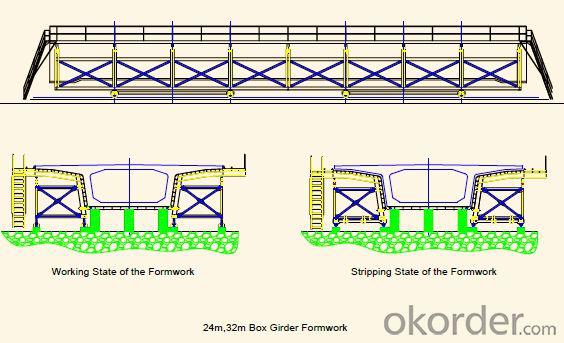

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: How to put the beam formwork in concrete structure

- By way of hanging on the board, you do not want to put a line for you!

- Q: What kind of frame beam formwork

- Frame beam template, single beam, continuous beam template section, beam set beam template in the middle section.

- Q: According to the experience, who knows the construction area and template, plate, column, beam volume, steel, etc.!

- Multi storey residential building structure of each floor area of square meters of content: the template to expand the area of about 2.4 to 2.9 square meters, concrete about 0.42 LiAbout 55 meters, reinforced to 65Kg.Basement floor area per square metre of content: the template to expand the area of about 2.4 to 3 square meters, concrete about 0.8 to 1.1 cubic meters,Steel bar about 125 to 170Kg.

- Q: The formula for the calculation of beam, concrete and brick

- (1) single beam, the support of the template is not deducted, the end of the template does not increase. Beam length(2) when the beam and beam intersect, the area of the main girder is not deducted.(3) beam, plate connection, beam wall template to plate ping.

- Q: How to do the foundation beam template

- The main body of each layer of concrete using fixed pump delivery. Before pouring, it is necessary to clear the debris in the template and advance the wet mode, the concrete vibration needs to be timely, coherent, and shall not leak slurry, reinforcement intensive place need to strengthen the vibration, to ensure the concrete density. Concrete vibrator should try to avoid the direct vibration of the template, to prevent the expansion of the joints at the seams, so as to set up the site to inspect the quality of the template.Wall column concrete pouring in place, to prevent the beam, the plate when pouring overflow phenomenon affect the appearance quality, the wall column concrete pouring should be carried out in time for two times to ensure that the structure section size is correct, the founder does not distort deformation.

- Q: Seeking beam, plate template engineering quantity

- The second beam template (bottom area +2* side area): (2.6*3- wall thickness) * (0.2+ (0.4-0.12) *2) *2-0.2*0.25*4 [the main beam and the secondary beam transfer area] -0.2*0.4*2*4 [the main beam and secondary beam transfer area]

- Q: A set of 50 m T beam steel template weight

- Fifty m T beam steel formwork, a complete set of general must contain a set of side beams in the beam half

- Q: How to control the elevation of the beam bottom and the axis position

- The axis is controlled by hanging the ball down to the lower floor axis and the axis control line.

- Q: What is the formula of beam slab formwork

- Si=F*A*B, formula, F coefficient, A, length, B width or height.Such as triangle F=0.5, A for the bottom edge of the length, B is high.

- Q: 10-3 degrees of weather, cast in situ floor and girder formwork can be demolished a few days? 25 days enough? There's a wall on the beam.

- If it is summer side touch about 5-7 days is not a problem, the floor of the bottom mold principle that needs to be kept until the floor block to achieve strong design. After the test block strength test qualified to dismantle the bottom mold testing stations in concrete, but in the bottom die and the support under the premise of more than 7 days can be started in the above line ready on a layer of formwork, about 10 days can start pouring a layer of concrete.

Send your message to us

Wholely Assembled Box Girder Template Made in China with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords