Waterproof Safe Single - Side Climbing Formwork For Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

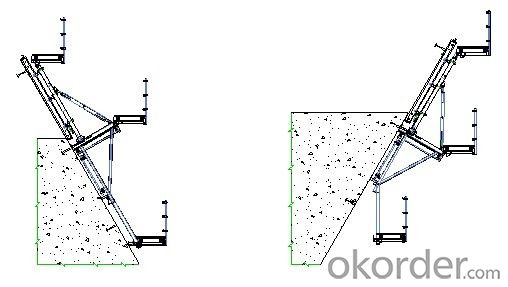

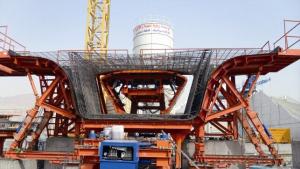

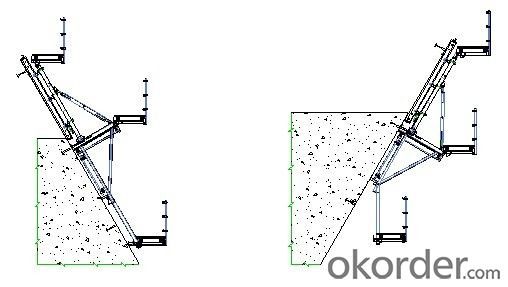

1. Structure of Waterproof Safe Single - Side Climbing Formwork For Wall

With CMAX SCB180 climbing systems, the loads from the fresh concrete pressure are transferred through the brackets by means of V-strong backs and compression braces into the scaffold anchors.

Typical applications for the SCB 180 system are dams, locks, cooling towers, pier heads, tunnels, and bank vaults.

The formwork is simply tilted backwards when striking takes place. The 1.80 m wide bracket requires only a minimum of space.

2. Main Features of Waterproof Safe Single - Side Climbing Formwork For Wall

A) Economical and safe anchoring

The M30/D20 climbing cones have been designed especially for single-sided concreting using SCB180 in dam construction, and to allow the transfer of high tensile and shear forces into the still fresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.

B) Stable and cost-effective for high loads.

Generous bracket spacing allow large-area formwork units with optimal utilization of the bearing capacity. This leads to extremely economical solutions.

C) Simple and flexible planning

With SCB180 single-sided climbing formwork, circular structures can also be concreted without undergoing any large planning process. Even use on inclined walls is feasible without any special measures because additional concrete loads or lifting forces can be safely transferred into the structure.

D) It is with the advantages of standard design, excellent applicability and interchangeable.

3. Waterproof Safe Single - Side Climbing Formwork For Wall Images

4. Waterproof Safe Single - Side Climbing Formwork For Wall Specification

5. FAQ of Waterproof Safe Single - Side Climbing Formwork For Wall

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Waterproof Safe Single - Side Climbing Formwork For Wall, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of TWaterproof Safe Single - Side Climbing Formwork For Wall, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Should not be on the front and back of the four sides of the template? Why is the width of the beam length multiplied by the beam surface? Isn't that the three face?

- Only the surface and the side surface of the template, when pouring the concrete pouring can together from above.

- Q: I only see the span is greater than 4M of the beam arch height is 1/1000~3/1000, if that is 5m, 8m, 12M, 16m and even assuming 20m, the supply is only 1/1000~3/1000????

- 1, in order to prevent the concrete weight and construction load to other beam and plate template pendulous; if there is no design provisions, the arch height is the length of the cross beam and plate 1/1000~3/1000; (general wood template for 1.5/1000~3/1000; steel template for 1.5/1000~2/1000.)

- Q: How to do irrigation formwork

- For your understanding of the 200*350, this is the inside of the beam height. The true beam is 200*500. without the need to deduct plate thickness

- Q: The formwork support is a beam template which is connected with both sides of the vertical rod and the force at the bottom of the beam and the force of the vertical wire rod which is arranged below the transverse beam at the bottom of the beam

- This option is not available in the design parametersCan only be used in the calculation of the calculation of the book or the program alone: double fastener!

- Q: There are times when the beam is not to deduct the secondary beam on the main part of the beam?

- The bottom of the beam is provided with two side edges, and the side edges are counted to the bottom of the plate

- Q: How to support 6m arc beam template how to set up?

- If you use a supporting beam of radian template, the bottom surface made of a whole block template (template block with good reinforcement, pouring backwater) after dismantling the entire arc shape template on the line; if the second half of the same radian can do a whole half arc template do the bottom die.

- Q: How to calculate the intersection of rectangular column and beam

- Column high: beam slab column column should be high since the surface (or floor surface) first height calculation between the surface layer of the floor slab; column height should be from column surface (or floor surface) to calculate the height of column cap between the lower surface of the frame column should be high; the height calculated from the upper surface to the top of the column base; structural column height should be at the bottom of the column to column (from beam bottom) height calculation;

- Q: The main floor beam template installation should pay attention to what?

- 2) install the side formwork of the beam and drill the side of the side of the side of the pull screw hole after the additional diagonal reinforcement.3 check the beam center line, elevation, section size, adjacent beam column template connection is fixed.4) after the beam and plate steel reinforcement is finished, the 1/2 pairs of the beam height are put on the pull screw, and the outer part of the pull screw is coated with a hard PVC casing, and the screw spacing is 1000mm.

- Q: First of all, what are the construction of the structure of the template, such as walls, columns, beams and ladders, which is the structure of the first installation of the template after the installation of steel? Ten

- On the contrary, the beam plate is the first template, tied after the reinforcement, because the beam plate is flat, the first binding steel, do you want to let the first suspension? That's not going to collapse

- Q: 10-3 degrees of weather, cast in situ floor and girder formwork can be demolished a few days? 25 days enough? There's a wall on the beam.

- When the bottom formwork of the reinforced concrete slab with a span of 5m is removed, the concrete strength should be greater than or equal to 75% of the standard value of concrete cube compressive strength.

Send your message to us

Waterproof Safe Single - Side Climbing Formwork For Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords