55 SERIAL STEEL FRAMED FORMWORK FOR CONSTRUCTIONS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

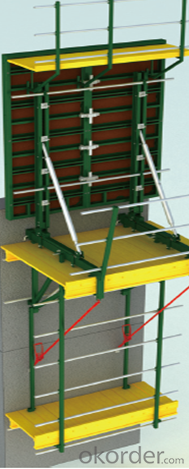

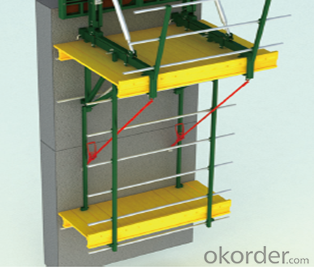

1. Structure of 120 Steel Framed Formwork Description

Single-side bracket is a kind of formwork for the concrete pouring of single-side wall. The construction is easy and fast. The components have good standard performance and versatility. The pouring height is adjustable, the maximum height of a single pouring is 8.9m.The formwork is always used in the concrete pouring of basement, subway, Sewage treatment factory and so on. The waterproof of the finished wall is excellent

2. Main Features of 120 Steel Framed Formwork

-easy to assemble

-simple structure.

-and convenient for transportation

-convenient for storage.

3. 120 Steel Framed Formwork Images

4. Single-side Steel Framed Formwork Specifications

5.FAQ of 120 Steel Framed Formwork

1) What can we do for you?

.We can ensure the quality of the 120 steel framed formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in single side steel framed formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Single side steel framed formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2 weeks.

- Q: When the span of the main girder in steel frame is large, it is necessary to arrange the secondary beam

- Size, generally not more than 2.7 meters, and shall not be less than 1.5 meters

- Q: Are there any specific guidelines for pouring concrete into steel frame formwork?

- Yes, there are specific guidelines for pouring concrete into steel frame formwork. Here are some of the key guidelines to follow: 1. Ensure the formwork is properly secured: Before pouring the concrete, make sure the steel frame formwork is securely anchored to prevent any movement or displacement during the pouring process. This will help maintain the structural integrity of the concrete once it sets. 2. Prepare the formwork: Clean the steel frame formwork thoroughly before pouring concrete. Remove any debris, dust, or loose particles that may affect the quality of the concrete. Additionally, apply a release agent or formwork oil to the inner surface of the formwork to facilitate easy removal after the concrete sets. 3. Reinforce the formwork: If necessary, reinforce the steel frame formwork with additional steel bars or mesh to provide extra strength and stability. This is especially important for pouring large or complex structures that require additional reinforcement to withstand the pressure of the concrete. 4. Place concrete in sections: Pour the concrete in sections rather than filling the entire formwork at once. This will help prevent the concrete from settling or segregating, ensuring a consistent density and strength throughout the structure. 5. Compact the concrete: Use appropriate compaction techniques, such as vibrating or tamping, to eliminate any air pockets or voids within the concrete. This will enhance the structural integrity and improve the overall quality of the finished product. 6. Allow for proper curing: After pouring the concrete, ensure proper curing by providing adequate moisture and temperature conditions. This will help the concrete achieve its desired strength and durability over time. Follow the recommended curing guidelines provided by the concrete supplier or engineer. 7. Monitor the pouring process: Throughout the pouring process, closely monitor the concrete flow, ensuring it fills the formwork evenly and without any obstructions. Pay attention to any potential issues, such as leakage or excessive bleeding, and take necessary actions to rectify them promptly. Overall, following these specific guidelines for pouring concrete into steel frame formwork will help ensure a successful and structurally sound concrete structure. However, it is always recommended to consult with a professional engineer or concrete specialist for specific guidelines and recommendations based on the project requirements and local building codes.

- Q: Are there any limitations on the height of structures that can be constructed using steel frame formwork?

- Yes, there are limitations on the height of structures that can be constructed using steel frame formwork. The height limitation primarily depends on the design and engineering considerations, as well as the capabilities of the steel frame formwork system being used. One of the main factors that can limit the height is the load-bearing capacity of the steel frame formwork. The formwork needs to be able to support the weight of the concrete and any additional loads, such as construction equipment or workers. If the height of the structure exceeds the load-bearing capacity of the formwork, it can lead to structural instability and potential collapse. Additionally, the stability and rigidity of the steel frame formwork system play a crucial role in determining the maximum height. As the height increases, the formwork system needs to be able to withstand the lateral forces, wind loads, and other external factors that can affect the stability of the structure. If the formwork system is not designed to handle these forces, it can compromise the safety and integrity of the construction. Moreover, the availability of suitable equipment and technology can also impose limitations on the height of structures constructed using steel frame formwork. Taller structures may require specialized equipment, such as high-capacity cranes or lifting systems, to assemble and dismantle the formwork. If such equipment is not available or feasible, it can restrict the height that can be achieved using steel frame formwork. Lastly, local building codes and regulations also often dictate the maximum height of structures. These regulations are put in place to ensure the safety and stability of buildings and to prevent any potential risks to the surrounding environment. It is important to adhere to these regulations and obtain appropriate permits when constructing tall structures using steel frame formwork. In conclusion, while steel frame formwork offers versatility and strength in construction, there are limitations on the height of structures that can be built using this system. The load-bearing capacity, stability, availability of equipment, and local regulations are some of the factors that determine the maximum height achievable. It is essential to consult with experienced engineers and adhere to safety guidelines to ensure the successful construction of tall structures using steel frame formwork.

- Q: What are the key safety features of steel frame formwork?

- The key safety features of steel frame formwork include: 1. Durability: Steel is a strong and sturdy material that can withstand heavy loads and external forces, ensuring the safety of workers and the structure itself. 2. Stability: The steel frame formwork system provides excellent stability due to its rigid structure. It can resist shifting or collapsing during concrete pouring, minimizing the risk of accidents. 3. Easy assembly and disassembly: Steel frame formwork is designed for quick and easy installation and removal. The components can be easily connected and disconnected, reducing the time workers spend on the construction site and minimizing the chances of accidents. 4. Adjustable design: Steel frame formwork systems often feature adjustable components, such as telescopic props and adjustable brackets. This allows for precise positioning and alignment, ensuring the formwork is secure and stable. 5. Safety accessories: Steel frame formwork is often equipped with safety accessories such as handrails, toe boards, and safety nets. These accessories provide additional protection for workers, preventing falls and injuries. 6. Fire resistance: Steel is a non-combustible material, making steel frame formwork highly resistant to fire. This feature enhances the overall safety of the construction site and reduces the risk of fire-related accidents. 7. Load-bearing capacity: Steel frame formwork is designed to withstand heavy loads, ensuring the safety of workers and preventing any structural failures. This feature is particularly important in high-rise constructions or projects with significant load requirements. 8. Compatibility with other safety systems: Steel frame formwork can be easily integrated with other safety systems, such as scaffolding or fall protection equipment. This ensures a comprehensive safety setup on the construction site, reducing the risk of accidents and injuries. Overall, the key safety features of steel frame formwork make it a reliable and secure option for construction projects. Its durability, stability, easy assembly, adjustable design, safety accessories, fire resistance, load-bearing capacity, and compatibility with other safety systems all contribute to creating a safe working environment for construction workers.

- Q: How does steel frame formwork handle the placement of façade elements and architectural features within the concrete structure?

- Steel frame formwork provides a versatile and flexible solution for handling the placement of façade elements and architectural features within the concrete structure. The steel frames can be adjusted and customized according to the specific requirements of the design, allowing for precise positioning of elements such as windows, doors, and decorative façade panels. Additionally, the steel frame formwork provides strong support and stability during the pouring and setting of the concrete, ensuring that the architectural features are seamlessly integrated into the structure.

- Q: Can steel frame formwork be used for both cast-in-place and precast concrete structures?

- Both cast-in-place and precast concrete structures can utilize steel frame formwork. This versatile formwork can easily adapt to various construction methods. In the case of cast-in-place concrete structures, the steel formwork is set up on-site, and the concrete is directly poured into it. After the concrete has fully cured, the formwork is removed, leaving behind the cast-in-place structure. Likewise, steel frame formwork is also applicable to precast concrete structures. Here, the steel formwork is employed to create molds or casts for the precast elements off-site. The concrete is poured into these molds, allowed to cure, and subsequently transported to the construction site for installation. The steel formwork can be conveniently disassembled and reused for multiple precast elements, making it a cost-effective choice for precast concrete structures. In conclusion, steel frame formwork provides flexibility and efficiency in construction, rendering it suitable for both cast-in-place and precast concrete structures.

- Q: Can steel frame formwork be used in corrosive environments?

- No, steel frame formwork is not recommended for use in corrosive environments as it is susceptible to rust and corrosion.

- Q: How does steel frame formwork help in achieving accurate concrete leveling?

- Achieving precise concrete leveling is made possible with the use of steel frame formwork, as it offers a rigid and stable structure for pouring and shaping the concrete. Designed to be strong and durable, the steel frames maintain their shape and alignment throughout the entire pouring process. One major advantage of steel frame formwork is the ability to have precise control over the concrete placement and leveling. The frames can be easily adjusted and aligned to the desired height and slope, ensuring accurate pouring. This eliminates any inconsistencies or unevenness in the final concrete surface. Furthermore, steel frame formwork provides exceptional support and stability, preventing any deformation or movement during the pouring and curing of the concrete. This guarantees that the concrete maintains its intended shape and level, even under the pressure of the wet mix and its own weight. Additionally, the steel frames minimize the risk of concrete shrinkage and settlement, which can occur if the formwork is not adequately supported. By providing a strong and rigid structure, the frames distribute the weight of the concrete evenly, reducing the chances of sinking or settling after curing. Moreover, steel frame formwork is highly adaptable and can be easily customized to fit various shapes and sizes of concrete structures. This allows for accurate leveling, even in complex and irregular designs. In conclusion, steel frame formwork is essential in achieving accurate concrete leveling by offering a stable and adjustable structure for pouring and shaping. Its strength, stability, and versatility ensure that the concrete maintains its desired level and shape, resulting in a high-quality and level finished surface.

- Q: Can steel frame formwork be used for precast concrete cladding?

- Yes, steel frame formwork can be used for precast concrete cladding. Steel frame formwork is commonly used in the construction industry for its durability and strength. It provides a sturdy structure for pouring and shaping concrete, making it suitable for creating precast concrete cladding panels. The steel frame formwork ensures the desired shape and dimensions of the cladding are achieved, resulting in a high-quality finish.

- Q: How does steel frame formwork accommodate for different concrete curing methods?

- The use of steel frame formwork in construction offers great flexibility in accommodating various concrete curing methods. It allows for the utilization of different curing materials, including water, steam, or chemicals, depending on the desired outcome. This is made possible by the strong and resilient nature of steel, which can withstand the extreme temperatures and pressures associated with steam curing, as well as the corrosive effects of certain chemicals. Furthermore, steel frame formwork can be easily adjusted or modified to create different curing environments. For instance, if a particular section of the concrete structure requires accelerated curing, temporary enclosures can be constructed using steel panels to retain the necessary heat and moisture for faster curing. On the other hand, if a slower curing method is preferred, the steel formwork can be designed to allow for increased ventilation and air circulation, promoting natural air curing. Moreover, steel frame formwork offers a high level of customization, allowing for the integration of various curing systems or equipment. For example, heating elements or pipes can be embedded within the formwork to provide controlled heating or cooling during the curing process. This is especially advantageous in situations where a specific temperature range needs to be maintained for optimal concrete strength development. Additionally, the reusability of steel frame formwork is a significant advantage. It can be easily disassembled and reassembled for different projects or sections of a structure. This feature allows for the implementation of different curing methods based on specific project requirements or resource availability. In conclusion, steel frame formwork is a versatile construction technique that can accommodate a wide range of concrete curing methods. Its durability, adaptability, customizability, and reusability make it an ideal choice for meeting various curing requirements, whether they involve water, steam, chemicals, accelerated curing, or natural air curing.

Send your message to us

55 SERIAL STEEL FRAMED FORMWORK FOR CONSTRUCTIONS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords