STEEL FRAMED FORMWORK AND ITS ACCESSORIES FOR BUILDING CONSTRUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

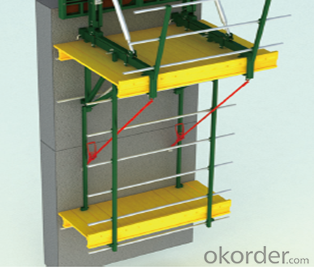

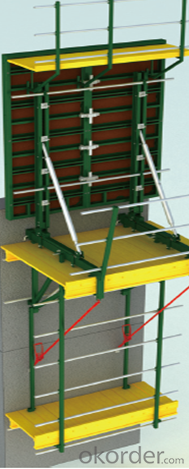

1. Structure of 120 Steel Framed Formwork Description

Single-side bracket is a kind of formwork for the concrete pouring of single-side wall. The construction is easy and fast. The components have good standard performance and versatility. The pouring height is adjustable, the maximum height of a single pouring is 8.9m.The formwork is always used in the concrete pouring of basement, subway, Sewage treatment factory and so on. The waterproof of the finished wall is excellent

2. Main Features of 120 Steel Framed Formwork

-easy to assemble

-simple structure.

-and convenient for transportation

-convenient for storage.

3. 120 Steel Framed Formwork Images

4. Single-side Steel Framed Formwork Specifications

5.FAQ of 120 Steel Framed Formwork

1) What can we do for you?

.We can ensure the quality of the 120 steel framed formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in single side steel framed formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Single side steel framed formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2 weeks.

- Q: How does steel frame formwork prevent leakage and seepage of concrete during pouring?

- Leakage and seepage of concrete during pouring can be prevented by steel frame formwork through various mechanisms. To begin with, the steel frame formwork is meticulously designed to guarantee tight joints and connections, leaving no room for any gaps or openings through which the concrete might escape. The formwork is carefully aligned and secured, creating a watertight seal that minimizes the risk of leakage. Furthermore, high-quality materials resistant to water penetration are utilized in the construction of steel frame formwork. The steel panels employed in the formwork are typically coated with protective layers such as galvanized or epoxy coatings, acting as a barrier against water and safeguarding the concrete pouring process from any compromise. Moreover, steel frame formwork is engineered with ample support and bracing to endure the pressure exerted by the concrete during pouring. This guarantees the stability and integrity of the formwork, further reducing the likelihood of leakage or seepage. Additionally, steel frame formwork often incorporates additional sealing elements like rubber gaskets or foam strips in critical areas prone to leakage or seepage, such as corners or joints. These components provide an extra layer of protection, aiding in the creation of a tight seal and preventing any unwanted water ingress. In conclusion, the combination of precise design, high-quality materials, proper support, and additional sealing elements in steel frame formwork proves to be an effective solution in preventing leakage and seepage of concrete during pouring. This ensures the preservation of the poured concrete's integrity and quality, resulting in a durable and dependable structure.

- Q: What are the different types of form release agents used with steel frame formwork?

- There are primarily two types of form release agents used with steel frame formwork: barrier release agents and chemically reactive release agents. Barrier release agents create a physical barrier between the formwork and the concrete, preventing adhesion. Chemically reactive release agents chemically react with the concrete, forming a slippery film that allows for easy release.

- Q: What are the key quality control measures for steel frame formwork installation?

- To ensure the structural integrity and safety of the formwork system, it is crucial to follow several key quality control measures for steel frame formwork installation. These measures are as follows: 1. Thoroughly inspect the steel frame formwork before commencing installation. This involves checking for damages, defects, or missing components. Address and resolve any issues before proceeding. 2. Ensure accurate alignment of the steel frame formwork to achieve a seamless fit and stable structure. Check the vertical and horizontal alignment, as well as the levelness and plumbness of the components. 3. Secure the connections between the steel frame formwork components tightly and securely. Use appropriate fasteners such as bolts or screws, and ensure they are properly tightened to avoid instability. 4. Level and flatten the surfaces of the steel frame formwork to provide a stable and uniform support for the concrete. Use leveling tools like spirit levels or laser levels to align and adjust the formwork. 5. Properly place and secure reinforcement bars if required in the formwork system. Ensure correct positioning and adequate support to prevent displacement during concrete pouring. 6. Adequately brace the steel frame formwork to prevent deformation or collapse. Use diagonal braces or stiffeners and ensure all bracing components are properly secured and tightened. 7. Conduct regular inspections and maintenance throughout the installation process to identify potential issues or defects. Repair or replace any damages or defects immediately to ensure safety and effectiveness. By adhering to these key quality control measures, the steel frame formwork installation can be carried out efficiently and effectively, resulting in a robust and reliable structure for concrete casting.

- Q: How does steel frame formwork contribute to faster construction times?

- There are several ways in which steel frame formwork speeds up construction. Firstly, steel formwork is incredibly durable and can withstand the pressure and weight of concrete without warping or deforming. This means it can be used multiple times, saving time and effort during installation and removal. In addition, steel frame formwork systems are designed to be easily assembled and disassembled, allowing for quick construction and dismantling. These systems are modular, meaning adjustments and modifications can be made easily, saving time and ensuring accuracy. Furthermore, steel formwork provides a smooth and even surface finish, eliminating the need for additional plastering or finishing work. This saves both time and money during the final stages of construction. Moreover, steel frame formwork allows for efficient pouring and curing of concrete. The tight joints and secure connections between the formwork elements ensure the concrete is properly contained and shaped during pouring. This eliminates the need for additional support structures and reduces the risk of concrete leakage or collapse. Overall, the strength, reusability, easy assembly, and efficient pouring capabilities of steel frame formwork all contribute to faster construction times by reducing labor and time for formwork installation, providing a smooth surface finish, and facilitating rapid concrete pouring and curing processes.

- Q: What are the different types of formwork pins used in steel frame formwork systems?

- There are several different types of formwork pins that are commonly used in steel frame formwork systems. These pins are essential for securing the formwork panels and ensuring the stability of the entire structure. Some of the different types of formwork pins used in steel frame formwork systems include: 1. Wedge pins: These are the most commonly used formwork pins and are designed to secure the formwork panels together. They have a wedge shape that allows them to be easily inserted and removed. Wedge pins are typically made of steel and are available in various sizes to accommodate different thicknesses of formwork panels. 2. Flathead pins: These pins have a flat head and are used to hold the formwork panels in place. They are inserted through holes in the formwork panels and secured with a nut or washer on the opposite side. Flathead pins provide a secure connection and are often used in combination with other types of pins for added stability. 3. Connecting pins: These pins are used to connect two or more formwork panels together. They typically have a threaded end that allows them to be screwed into the panels. Connecting pins are commonly used in situations where a tight and secure connection is required, such as when forming corners or curved walls. 4. Tapered pins: These pins have a tapered shape, with one end being larger than the other. They are used to align and secure formwork panels by inserting the larger end into pre-drilled holes in the panels. Tapered pins provide a tight fit and are often used in conjunction with other types of pins for added stability. 5. Snap pins: These pins have a snap-on design that allows them to be easily attached and detached from the formwork panels. They are typically made of plastic or metal and are used in situations where frequent assembly and disassembly of the formwork is required. Overall, the different types of formwork pins used in steel frame formwork systems serve the purpose of securing the formwork panels and ensuring the stability of the entire structure. The specific type of pin used will depend on factors such as the formwork system being used, the thickness of the panels, and the desired level of stability and security.

- Q: Can steel frame formwork be used for inclined or sloped concrete structures?

- Yes, steel frame formwork can be used for inclined or sloped concrete structures. Steel frame formwork provides a rigid structure that can be adjusted to different angles, allowing it to be used for various types of concrete structures, including inclined or sloped ones.

- Q: What are the safety precautions for transporting steel frame formwork?

- Some safety precautions for transporting steel frame formwork include securing the frames properly to prevent shifting or falling during transport, using appropriate lifting equipment and techniques to avoid injuries, ensuring that the load is within the weight capacity of the vehicle, and following all relevant transportation regulations and guidelines. It is also essential to inspect the formwork for any damages or defects before transportation to prevent accidents or structural failure.

- Q: Can steel frame formwork be used for both rectangular and irregularly shaped concrete elements?

- Both rectangular and irregularly shaped concrete elements can be constructed using steel frame formwork. This versatile and flexible system can be easily adjusted and customized to accommodate different shapes and sizes. It is composed of steel frames, panels, and accessories that can be assembled in various configurations to create the desired formwork shape. The strength and stability of the steel frames allow the formwork to withstand the pressure exerted by the wet concrete during pouring and curing. Furthermore, the panels can be easily adjusted or cut to fit irregular shapes, making it suitable for constructing elements with non-standard geometries. In summary, steel frame formwork is an reliable and effective solution for constructing both rectangular and irregularly shaped concrete elements.

- Q: What are the different types of formwork clamps used with steel frame formwork?

- There are several different types of formwork clamps that are commonly used with steel frame formwork. These clamps are designed to securely hold the formwork panels in place and ensure that they do not shift or move during the concrete pouring process. One type of formwork clamp that is often used with steel frame formwork is the wedge clamp. This type of clamp consists of a metal wedge that is inserted into a slot on the formwork panel and then tightened to secure the panel in place. The wedge clamp is easy to use and can be quickly adjusted or removed as needed. Another type of formwork clamp that is commonly used with steel frame formwork is the hook clamp. This type of clamp consists of a metal hook that is inserted into a hole on the formwork panel and then tightened to secure the panel in place. The hook clamp provides a strong and secure connection between the formwork panel and the steel frame. In addition to wedge and hook clamps, there are also other types of clamps that can be used with steel frame formwork. These include spring clamps, which use a spring mechanism to hold the formwork panels in place, and toggle clamps, which use a lever mechanism to securely fasten the panels. These clamps can be easily adjusted and provide a strong and reliable connection between the formwork panels and the steel frame. Overall, the different types of formwork clamps used with steel frame formwork provide a variety of options for securely holding the formwork panels in place. Each type of clamp has its own advantages and disadvantages, and the choice of clamp will depend on the specific requirements of the construction project.

- Q: What are the considerations for selecting the appropriate formwork for different concrete placements?

- There are several factors that need to be taken into account when selecting the appropriate formwork for different concrete placements. These factors include: 1. Considering the type of concrete placement, such as vertical walls, slabs, columns, or beams, will have an impact on the formwork selection. Each type requires specific formwork systems that can accommodate the required shape and size of the concrete structure. 2. The formwork must have the ability to withstand the weight and pressure exerted by the concrete during pouring and curing. It is crucial to choose a formwork system that has the appropriate load capacity for the specific concrete placement to ensure safety and structural integrity. 3. The duration for which the formwork will be in use is another important consideration. If the formwork will be used for a short period, a temporary formwork system such as timber or plywood may be suitable. However, for long-term projects or when multiple pours are required, more durable and reusable formwork systems like steel or aluminum may be preferable. 4. The desired surface finish of the concrete also affects the choice of formwork. If a smooth and uniform finish is required, formwork materials that have a smooth surface or can be easily coated with a release agent may be necessary. On the other hand, if a textured or patterned finish is desired, formwork materials that can accommodate such designs may be needed. 5. The cost-effectiveness of the formwork materials and installation should be considered in relation to the overall project budget. Different types of formwork systems have varying costs, and it is important to select a system that is cost-effective while still meeting the project requirements. 6. The availability and accessibility of the formwork materials and equipment should also be considered. It is important to choose formwork systems that are readily available in the local market and can be easily transported and assembled on-site. 7. The environmental impact of the formwork materials is another factor to be considered. Choosing sustainable and eco-friendly options, such as formwork materials made from recycled materials or those that can be recycled after use, can contribute to a more environmentally conscious construction process. By carefully considering these factors, contractors and engineers can ensure optimal construction efficiency, safety, and quality by selecting the appropriate formwork for different concrete placements.

Send your message to us

STEEL FRAMED FORMWORK AND ITS ACCESSORIES FOR BUILDING CONSTRUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords