Adjustable H20 Timber Beam Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Light weight,

high bearing capacity,

adjustable column walers

Adjustable H20 Timber Beam Formwork For Rectangle Concrete Column Formwork

Description:

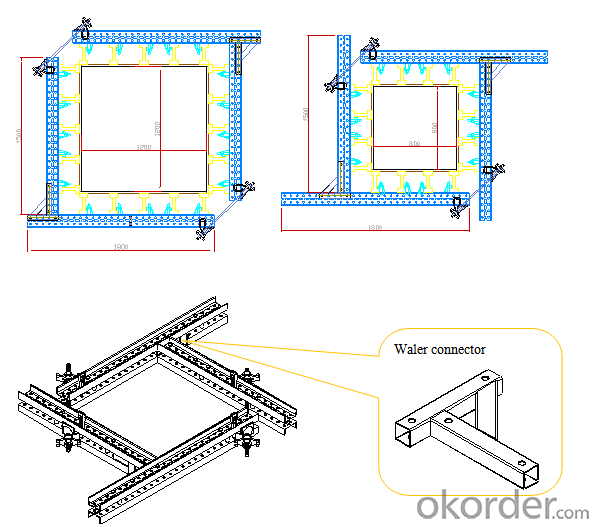

1. Structure sketch

TBC system-B is a kind of formwork for pouring square or rectangle column, it is composed of four pieces of Tim-formwork, yoke, tie rod, wing nut, etc.

It will be designed according to column’s size; the formwork’s dimension is adjustable.

Competitive Advantage:

1. Prefabricated connection, convenient and efficient.

2. Light weight but high bearing capacity.

For conventional design, its load bearing capacity is 80KN/m2 with weight of 55-65kg/m2.

If required, the formwork can be specially designed for high concrete pressures.

3. Adjustable cross-sections with adjustable column walers.

The column formwork for forming various cross-section and height. With the TBC-B, square or rectangular cross-sections up to 80 x 120 cm can be concreted – the formwork is continuous adjustable.

Applications:

- Q: What are the different types of reinforcement systems used with steel frame formwork?

- There are several different types of reinforcement systems used with steel frame formwork in construction projects. These reinforcement systems are designed to provide additional strength and stability to the formwork, ensuring that it can withstand the weight and pressure of the concrete being poured. One common type of reinforcement system used with steel frame formwork is the use of steel bars or rods. These bars are typically placed horizontally and vertically within the formwork to create a grid-like pattern. This grid of steel bars helps to distribute the weight and pressure of the concrete evenly, preventing the formwork from collapsing or deforming. Another type of reinforcement system used with steel frame formwork is the use of steel mesh or wire. This mesh or wire is typically placed within the formwork to provide additional reinforcement and prevent the concrete from cracking or breaking under pressure. The mesh or wire is usually secured in place using ties or clips, ensuring that it remains in position during the pouring and curing process. In addition to steel bars and mesh, other reinforcement systems used with steel frame formwork include the use of fiber-reinforced polymers (FRPs) and plastic or composite materials. These materials are lightweight, yet strong, and can provide excellent reinforcement to the formwork. FRPs are often used in situations where corrosion resistance is required, as they are not susceptible to rust or degradation. Overall, the choice of reinforcement system used with steel frame formwork will depend on factors such as the specific project requirements, the type and load of the concrete being poured, and the desired level of strength and stability needed. It is important to consult with a structural engineer or construction professional to determine the most suitable reinforcement system for a particular project.

- Q: Can steel frame formwork be used for the construction of hospitality facilities?

- Yes, steel frame formwork can be used for the construction of hospitality facilities. Steel frame formwork is a versatile and durable construction method that is commonly used in various types of building projects, including hospitality facilities. This type of formwork is made of steel frames, which are easy to assemble and disassemble, providing flexibility in the construction process. Steel frame formwork offers several advantages for the construction of hospitality facilities. Firstly, steel is a strong and durable material that can withstand the heavy loads and stresses often encountered in hospitality facilities. This ensures the stability and safety of the structure. Additionally, steel frame formwork allows for efficient construction processes. The frames can be easily adjusted and reused, reducing construction time and costs. This is particularly beneficial in the construction of hospitality facilities, where time is often of the essence in meeting project deadlines. Furthermore, steel frame formwork provides a high level of accuracy and precision in the construction process. The frames are designed to be straight and level, ensuring that the resulting structure is of high quality and meets design specifications. This is important in hospitality facilities, where aesthetics and attention to detail are crucial for creating a welcoming and visually appealing environment for guests. In conclusion, steel frame formwork can indeed be used for the construction of hospitality facilities. Its strength, durability, efficiency, and precision make it a suitable choice for this type of construction, providing a solid foundation for the creation of welcoming and well-built hospitality facilities.

- Q: Can steel frame formwork be used for both above-grade and below-grade concrete structures?

- Yes, steel frame formwork can be used for both above-grade and below-grade concrete structures. Steel frame formwork is highly versatile and durable, making it suitable for various construction projects. It provides strong support and stability, ensuring that concrete is properly shaped and cured, regardless of whether it is an above-grade or below-grade structure.

- Q: How does steel frame formwork handle different types of formwork edge protection?

- Steel frame formwork is highly versatile and can handle various types of formwork edge protection efficiently. It provides a sturdy and stable support structure for different edge protection methods such as timber, steel, or plastic formwork guards. The steel frame ensures the formwork edge protection is securely attached, preventing any accidental displacement or collapse during the concrete pouring process. Additionally, the strength and durability of steel frame formwork allow for easy integration with other safety measures, ensuring a safe and reliable construction process.

- Q: How does steel frame formwork handle the movement and settlement of a structure?

- The construction technique known as steel frame formwork utilizes steel frames to support the concrete during pouring and curing. One of the key advantages of this method is its capacity to handle the movement and settlement of a structure. Steel possesses a high level of tensile strength, which enables it to endure the forces caused by movement and settlement without deformation or failure. This quality is essential in construction due to the various types of movement and settlement that buildings undergo over time. First and foremost, steel frame formwork provides a rigid structure that evenly distributes the weight of the concrete across the foundation. This aids in minimizing any uneven settlement or movement that may arise. Furthermore, steel frame formwork is designed to be adaptable and flexible, allowing it to accommodate slight variations in the dimensions of the structure. This adaptability ensures that some movement can occur without compromising the integrity of the construction. This aspect is particularly crucial in regions with high levels of seismic activity, as it enables structures to withstand earthquakes and other ground movements. Moreover, steel frame formwork often features expansion joints, which enable the structure to expand and contract naturally without causing any damage. These joints play a vital role in areas with extreme temperature fluctuations, preventing the cracking of steel and concrete due to thermal expansion. In conclusion, steel frame formwork effectively manages the movement and settlement of a structure by providing a robust and flexible support system. Its high tensile strength, adaptability, and inclusion of expansion joints make it an ideal choice for withstanding the forces and movements that a building may encounter throughout its lifespan.

- Q: How does steel frame formwork contribute to the overall energy efficiency of a concrete structure?

- There are several ways in which steel frame formwork can enhance the energy efficiency of a concrete structure. Firstly, steel is an incredibly durable material that can be reused multiple times. This means that the need for new formwork materials for each concrete pour is reduced, resulting in a decrease in the energy required for manufacturing and transporting these components. Consequently, the overall embodied energy of the structure is reduced. Furthermore, steel frame formwork offers excellent thermal insulation properties, which help to minimize heat loss and gain. By reducing thermal bridging, the formwork contributes to the overall insulation performance of the building envelope. Consequently, there is a reduced need for additional insulation materials, resulting in a decrease in the energy required for heating and cooling the structure. Moreover, steel frame formwork allows for precise and accurate concrete placement. This ensures that the concrete structure is constructed with minimal wastage, thereby reducing the energy required for concrete production and transport. By optimizing the use of concrete, the formwork contributes to the overall energy efficiency of the structure. Additionally, steel frame formwork enables the incorporation of energy-efficient design features into the concrete structure. For instance, it provides the flexibility to integrate voids and recesses for installing insulation materials, ventilation systems, or other energy-saving components. This allows for the implementation of energy-efficient strategies, such as utilizing renewable energy sources or passive design techniques. In conclusion, steel frame formwork plays a crucial role in enhancing the energy efficiency of a concrete structure. Through reducing the embodied energy of construction materials, improving thermal insulation, minimizing concrete wastage, and enabling the integration of energy-saving design features, it proves to be a sustainable choice that optimizes the energy performance of the building.

- Q: Can steel frame formwork be used for both monolithic and modular slab construction?

- Both monolithic and modular slab construction can utilize steel frame formwork. This versatile and resilient system easily adjusts to different construction methods and requirements. In monolithic slab construction, steel frame formwork provides a stable and robust support structure for pouring concrete. The steel frames assemble and adjust effortlessly to achieve the desired shape and dimensions of the slab. With its ability to withstand concrete pressure and weight, the formwork guarantees a smooth and even finish. Similarly, steel frame formwork proves effective in modular slab construction. This approach involves manufacturing individual slab sections off-site and subsequently assembling them at the construction site. The steel frame formwork ensures precise and accurate assembly of the modular slabs, ensuring high-quality and consistent results. The strength and stability of the steel frames allow for safe transportation and installation of the modular slabs. In summary, steel frame formwork is a versatile solution suitable for both monolithic and modular slab construction. Its strength, durability, and adaptability make it an excellent choice for various construction projects.

- Q: How does steel frame formwork handle the load distribution of a structure?

- A versatile and strong system utilized in construction for effective load distribution of structures is steel frame formwork. The main characteristic of this formwork is its ability to evenly distribute weight and forces on the structure, ensuring a stable and balanced load distribution. To begin with, steel frame formwork is comprised of interconnected rigid and strong steel panels capable of withstanding heavy loads. These panels are assembled and fixed together to create a framework that serves as a support system for the structure. The design of the steel frame formwork is such that it evenly distributes the load across the panels, preventing concentration of forces in specific areas. Moreover, steel frame formwork offers high customization, allowing for precise adjustment and alignment of the panels. This adaptability enables the formwork system to accommodate structures with complex geometries or irregular shapes. By ensuring accurate alignment of the panels, the load distribution is optimized, avoiding localized stress points and ensuring a uniform distribution of forces. Furthermore, steel frame formwork has a high load-bearing capacity due to the strength and durability of steel. Steel is known for its robustness and resistance to deformation, enabling it to handle heavy loads without compromising the stability of the structure. The use of steel in the formwork system ensures even and efficient load distribution, minimizing the risk of structural failure or collapse. Additionally, steel frame formwork allows for the integration of additional reinforcement elements, such as steel bars or mesh, which further enhance the load distribution capabilities of the structure. These reinforcements provide additional strength and stiffness, ensuring that the load is evenly distributed across the entire formwork system. In conclusion, steel frame formwork is an excellent solution for managing load distribution in structures. Its strength, adaptability, and high load-bearing capacity enable it to evenly distribute weight and forces on the structure, ensuring a stable and balanced load distribution. This guarantees the structural integrity and safety of the building, making steel frame formwork a popular choice in the construction industry.

- Q: What are the different types of clamping systems used with steel frame formwork?

- There are several different types of clamping systems that are commonly used with steel frame formwork. These clamping systems are designed to securely hold the formwork panels together, ensuring that they remain in place during the concrete pouring process. One type of clamping system that is commonly used is the wedge clamp system. This system consists of wedge-shaped clamps that are inserted into slots on the formwork panels. As the wedges are driven into the slots, they create a tight and secure connection between the panels, preventing any movement or shifting. Another type of clamping system is the pin and wedge system. This system uses steel pins that are inserted into pre-drilled holes in the formwork panels. Once the pins are in place, steel wedges are driven into slots on the pins, creating a strong connection between the panels. Some clamping systems use a combination of pins and clamps. These systems typically have pins that are inserted into pre-drilled holes in the formwork panels, and clamps that are tightened around the pins to hold the panels together. In addition to these clamping systems, there are also systems that use bolts and nuts, as well as systems that use hydraulic or mechanical mechanisms to hold the formwork panels together. The choice of clamping system will depend on various factors, including the size and complexity of the formwork structure, the required strength and stability, and the specific requirements of the construction project. It is important to carefully consider these factors and select the appropriate clamping system to ensure the safety and success of the formwork installation.

Send your message to us

Adjustable H20 Timber Beam Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords