120 STEEL FRAMED FORMWORK FOR CONSTRUCTIONS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of 120 Steel Framed Formwork Description

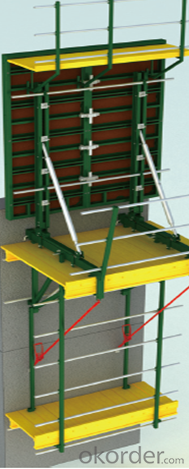

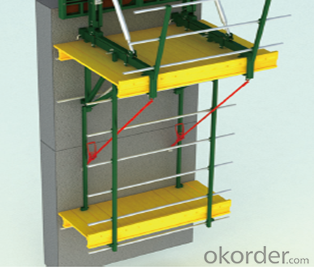

Single-side bracket is a kind of formwork for the concrete pouring of single-side wall. The construction is easy and fast. The components have good standard performance and versatility. The pouring height is adjustable, the maximum height of a single pouring is 8.9m.The formwork is always used in the concrete pouring of basement, subway, Sewage treatment factory and so on. The waterproof of the finished wall is excellent

2. Main Features of 120 Steel Framed Formwork

-easy to assemble

-simple structure.

-and convenient for transportation

-convenient for storage.

3. 120 Steel Framed Formwork Images

4. Single-side Steel Framed Formwork Specifications

5.FAQ of 120 Steel Framed Formwork

1) What can we do for you?

.We can ensure the quality of the 120 steel framed formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in single side steel framed formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Single side steel framed formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2 weeks.

- Q: What are the different surface treatments available for steel frame formwork?

- Some of the different surface treatments available for steel frame formwork include galvanization, painting, powder coating, and epoxy coating.

- Q: Can steel frame formwork be used for water retaining structures?

- Yes, steel frame formwork can be used for water retaining structures. Steel formwork systems are known for their strength, durability, and ability to withstand high pressure and water loads. They are commonly used in construction projects that involve building water tanks, reservoirs, swimming pools, and other structures that need to retain water. Steel frame formwork is designed to be watertight, preventing water from leaking out and ensuring the structural integrity of the water retaining structure. Additionally, steel formwork can be easily assembled, disassembled, and reused, making it a cost-effective option for such projects. However, it is important to ensure proper waterproofing measures are in place, such as using sealants or membranes, to further enhance the water resistance of the structure.

- Q: What are the different types of form ties used in conjunction with steel frame formwork?

- There are several types of form ties used in conjunction with steel frame formwork, including snap ties, wedge ties, coil ties, and flat ties. These ties are designed to hold the formwork together and provide stability during the concrete pouring process.

- Q: How does steel frame formwork contribute to the overall acoustics of a structure?

- Steel frame formwork does not directly contribute to the overall acoustics of a structure. The primary function of steel frame formwork is to provide temporary support and shape for the concrete during the construction process. It is a framework that holds the concrete in place until it hardens and gains its structural strength. However, the overall acoustics of a structure can be influenced by the materials and design choices made during the construction process. Factors such as the selection of building materials, insulation, and the design of walls, floors, and ceilings can have a significant impact on the sound transmission and absorption within a building. To improve the acoustics of a structure, specific acoustic measures need to be implemented, such as the use of sound-absorbing materials, acoustic insulation, and the design of spaces to reduce sound reflections. Steel frame formwork itself is not designed to contribute to these acoustic properties, but it can indirectly affect the acoustics by providing a strong and stable structure that allows for the installation of acoustic materials and soundproofing systems. In summary, while steel frame formwork does not directly contribute to the overall acoustics of a structure, it can play a role in providing a solid foundation for implementing acoustic measures that can enhance sound transmission and absorption within a building.

- Q: What is the average lifespan of a steel frame formwork system?

- The lifespan of a steel frame formwork system can differ based on a variety of factors. These factors include the quality of materials used, how often and how intensely the system is used, and the level of maintenance and care provided. Typically, a steel frame formwork system that is well-maintained can endure for many years, anywhere from 10 to 20 years or even longer. It's important to recognize that conducting regular inspections and repairs, as well as appropriately storing and handling the system, can significantly prolong its lifespan. Furthermore, elements like weather conditions, exposure to corrosive substances, and proper distribution of loads can also have an impact on how long a steel frame formwork system lasts.

- Q: Can steel frame formwork be used in areas with limited ventilation?

- Areas with limited ventilation can indeed accommodate the use of steel frame formwork. This construction solution, known for its versatility and durability, is frequently employed in a range of environments, including those lacking ample ventilation. Nevertheless, precautions must be taken to ensure safety when utilizing steel frame formwork in such areas. These precautions may involve the implementation of supplementary ventilation systems or adherence to additional safety protocols, aimed at mitigating any potential risks associated with the limited ventilation. Ultimately, it is essential to consider both the project's specific requirements and the applicable safety regulations before deciding to employ steel frame formwork in areas with limited ventilation.

- Q: Can steel frame formwork be used for both straight and curved concrete elements?

- Yes, steel frame formwork can be used for both straight and curved concrete elements. Steel frame formwork is versatile and can be easily adjusted and shaped to accommodate various angles and curves. The strength and rigidity of steel make it suitable for creating formwork that can withstand the pressure and forces exerted by the concrete during the pouring and curing process. Additionally, steel formwork can be reusable, making it a cost-effective choice for both straight and curved concrete elements.

- Q: Can steel frame formwork be used for both temporary and permanent structures?

- Indeed, steel frame formwork is applicable for both temporary and permanent structures. This adaptable and strong system finds utility in various construction projects, encompassing both temporary and permanent structures. Its robustness and stability render it suitable for prolonged usage in permanent structures, while its versatility and simplicity in assembly and disassembly make it an ideal choice for temporary structures too. Furthermore, steel frame formwork offers a high level of customization, enabling it to be tailored to meet diverse project requirements and specifications. Ultimately, steel frame formwork emerges as a dependable and effective solution for constructing both temporary and permanent structures.

- Q: Can steel frame formwork be used for bridge and infrastructure construction?

- Yes, steel frame formwork can be used for bridge and infrastructure construction. Steel frame formwork is a versatile and durable solution that provides efficient support for concrete during construction. It is especially suitable for large-scale projects like bridges and infrastructure due to its ability to withstand heavy loads and provide stability. Steel frame formwork offers several advantages for bridge and infrastructure construction. Firstly, it allows for quick and accurate assembly, ensuring a high level of precision and quality in concrete placement. This is crucial in bridge construction where precise alignment is essential for structural integrity. Secondly, steel frame formwork is highly reusable, making it cost-effective and environmentally friendly. With proper maintenance and care, steel formwork can be used for multiple projects, reducing the need for new formwork materials and minimizing waste. Additionally, steel frame formwork provides excellent strength and stability, making it suitable for large spans and heavy loads, which are common in bridge and infrastructure construction. The steel frames can withstand the pressure exerted by wet concrete and ensure the structural integrity of the construction. Moreover, steel formwork systems offer flexibility in design and can be customized to meet specific project requirements. This allows engineers and contractors to adapt the formwork to the unique shape and size of the bridge or infrastructure being constructed. In summary, steel frame formwork is a reliable and efficient solution for bridge and infrastructure construction. Its strength, durability, reusability, and flexibility make it an ideal choice for these types of projects, ensuring the successful completion of complex structures with high-quality concrete placement.

- Q: How does steel frame formwork affect the overall sound insulation of a concrete structure?

- Steel frame formwork does not directly affect the overall sound insulation of a concrete structure. Sound insulation primarily depends on the thickness and density of the concrete, as well as the presence of additional soundproofing materials such as insulation boards or acoustic barriers. The steel frame formwork, which is used as a temporary structure to support the concrete during construction, does not significantly contribute to or diminish the sound insulation properties of the finished concrete structure.

Send your message to us

120 STEEL FRAMED FORMWORK FOR CONSTRUCTIONS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords