STEEL FRAMED FORMWORK FOR CONSTRUCTIONS ALL THE WORLD

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

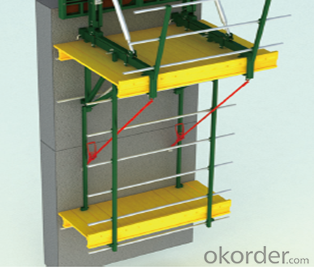

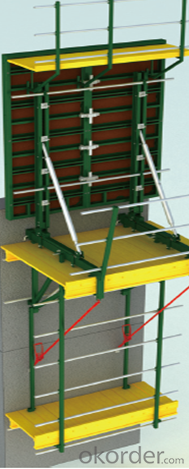

1. Structure of 120 Steel Framed Formwork Description

Single-side bracket is a kind of formwork for the concrete pouring of single-side wall. The construction is easy and fast. The components have good standard performance and versatility. The pouring height is adjustable, the maximum height of a single pouring is 8.9m.The formwork is always used in the concrete pouring of basement, subway, Sewage treatment factory and so on. The waterproof of the finished wall is excellent

2. Main Features of 120 Steel Framed Formwork

-easy to assemble

-simple structure.

-and convenient for transportation

-convenient for storage.

3. 120 Steel Framed Formwork Images

4. Single-side Steel Framed Formwork Specifications

5.FAQ of 120 Steel Framed Formwork

1) What can we do for you?

.We can ensure the quality of the 120 steel framed formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in single side steel framed formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Single side steel framed formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2 weeks.

- Q: How does steel frame formwork handle the placement of embedments and fixtures within the concrete structure?

- Steel frame formwork is a popular choice for constructing concrete structures due to its durability and strength. When it comes to handling the placement of embedments and fixtures within the concrete structure, steel frame formwork offers several advantages. Firstly, steel frame formwork provides a rigid and stable framework for the concrete, ensuring that embedments and fixtures are securely held in place during the pouring and curing process. The steel frame acts as a support system, preventing any movement or displacement of the embedments, such as rebar or electrical conduits, while the concrete sets. Additionally, steel frame formwork allows for precise positioning of embedments and fixtures. The formwork system typically consists of modular panels or frames that can be easily adjusted and aligned to accommodate the desired location and layout of embedments. This flexibility enables contractors to accurately place embedments and fixtures as per the project specifications, ensuring proper functionality and structural integrity. Furthermore, steel frame formwork provides ample space and accessibility for embedments and fixtures. The formwork system is designed to have pre-determined openings or penetrations, allowing for the easy insertion of embedments and fixtures within the concrete structure. This feature ensures that embedments can be easily integrated into the concrete, without the need for additional modifications or alterations. Moreover, steel frame formwork facilitates the installation of fixtures within the concrete structure. Fixtures such as electrical boxes, plumbing pipes, or HVAC components can be securely attached to the steel frame using various methods, such as welding or bolting. The robust nature of steel ensures that the fixtures are firmly anchored, providing long-term stability and support. In summary, steel frame formwork is well-suited to handle the placement of embedments and fixtures within the concrete structure. Its rigidity, precision, accessibility, and strength make it an ideal choice for safely and effectively incorporating embedments and fixtures into the concrete, ensuring a reliable and durable construction.

- Q: What are the quality control measures for steel frame formwork removal?

- Some quality control measures for steel frame formwork removal include inspecting the formwork for any damage or defects before removal, ensuring that the removal process does not cause any damage to the concrete structure, and conducting a final inspection to ensure that all formwork components have been properly removed and that the area is clean and ready for the next construction phase.

- Q: Can steel frame formwork be used for high-temperature industrial structures?

- Indeed, high-temperature industrial structures can utilize steel frame formwork. The exceptional strength and durability of steel render it apt for enduring elevated temperatures. Its remarkably high melting point enables it to preserve its structural integrity even under intense heat circumstances. Furthermore, steel possesses remarkable fire resistance properties, rendering it a secure option for environments with high temperatures. Nevertheless, meticulous design and construction of the steel frame formwork are crucial to withstand the precise temperature prerequisites of the industrial structure. This could entail incorporating heat-resistant coatings or insulation materials to safeguard the steel against excessive heat and avert any potential harm.

- Q: Does steel frame formwork require any specific reinforcement detailing?

- Yes, steel frame formwork does require specific reinforcement detailing. Steel frame formwork is a system used in construction for creating concrete structures. It consists of steel frames, typically made of steel beams and columns, which are used to support plywood panels or other formwork materials. The steel frames themselves need to be designed and reinforced to ensure they can withstand the loads of the concrete and the pressure exerted during the pouring and curing process. This includes determining the appropriate size and spacing of the steel beams and columns, as well as the reinforcement detailing within these elements. Reinforcement detailing for steel frame formwork typically involves providing additional steel bars or mesh within the beams and columns to enhance their strength and durability. This reinforcement helps to prevent bending, buckling, or failure of the steel frame under the weight and pressure of the concrete. The specific detailing requirements will depend on factors such as the size and height of the structure being formed, the anticipated loads, and local building codes and regulations. In addition to the reinforcement within the steel frame, other reinforcement detailing may be required for the concrete itself. This includes the placement and spacing of steel rebars within the concrete to provide additional strength and structural integrity. The specific reinforcement detailing for the concrete will depend on factors such as the design requirements, structural calculations, and the intended use and load-bearing capacity of the structure. Overall, steel frame formwork does require specific reinforcement detailing to ensure the structural integrity and safety of the formwork system and the resulting concrete structure. Professional engineers and designers play a crucial role in determining the appropriate reinforcement detailing for steel frame formwork, considering the specific requirements and conditions of each construction project.

- Q: How does steel frame formwork handle different types of concrete admixtures?

- Steel frame formwork is a versatile and durable method for constructing concrete structures, and it can easily handle different types of concrete admixtures. Concrete admixtures are substances that are added to the concrete mix to enhance certain properties or characteristics of the final product. These admixtures can include accelerators, retarders, plasticizers, superplasticizers, air-entraining agents, and many others. Steel frame formwork provides a strong and rigid structure that can withstand the pressure and forces exerted by the concrete mix, regardless of the type of admixture used. The formwork system consists of steel panels, usually with plywood facing, that are connected together with strong and reliable locking mechanisms. This ensures that the formwork remains stable and secure during the pouring and curing process. When it comes to different types of concrete admixtures, steel frame formwork can easily accommodate them. For example, if an accelerator is added to the concrete mix to speed up the curing time, the steel frame formwork can handle the increased early strength development without any issues. Similarly, if a retarder is used to slow down the setting time, the formwork can provide the necessary support and stability during the extended curing period. Steel frame formwork is also compatible with plasticizers and superplasticizers, which are admixtures that improve the workability and flowability of the concrete mix. These admixtures increase the fluidity of the concrete, allowing it to easily flow and fill the formwork. The steel frame provides the necessary strength and rigidity to contain the highly fluid concrete mix and prevent any leakage or deformation. Furthermore, steel frame formwork can also handle air-entraining agents, which are admixtures that introduce tiny air bubbles into the concrete mix. These air bubbles improve the freeze-thaw resistance of the concrete and enhance its durability. The steel frame formwork ensures that the air-entrained concrete remains intact and properly consolidated during the pouring and curing process. In summary, steel frame formwork is well-equipped to handle different types of concrete admixtures. Its strength, stability, and compatibility with various admixtures make it a reliable choice for constructing concrete structures with enhanced properties and characteristics.

- Q: How does steel frame formwork contribute to the overall durability of a concrete structure?

- Steel frame formwork contributes to the overall durability of a concrete structure by providing a strong and rigid framework that ensures proper alignment and support during the pouring and setting of concrete. This formwork system helps in achieving accurate dimensions and preventing any deformation or cracking of the concrete. Additionally, the steel frame formwork is highly resistant to wear and tear, corrosion, and other environmental factors, thus enhancing the longevity and durability of the concrete structure.

- Q: Can steel frame formwork be adjusted to different sizes and shapes?

- Steel frame formwork has the ability to adapt to various sizes and shapes. It is a versatile construction tool that can be easily adjusted and customized. By assembling and disassembling the frames, different dimensions and shapes can be accommodated for different construction projects. This flexibility enables the construction of walls, columns, beams, and other structural elements of different sizes and shapes. Furthermore, steel frame formwork can be combined with other formwork systems to enhance its adaptability even more, making it a popular choice among construction professionals.

- Q: Can steel frame formwork be used in areas with limited natural light?

- Indeed, areas with limited natural light can accommodate the utilization of steel frame formwork. Specifically engineered to offer support and structure during construction, this type of formwork does not rely on natural light for its effectiveness. Consequently, in areas lacking natural light, the use of artificial lighting sources like floodlights or construction site lighting can be implemented to guarantee adequate visibility and safety throughout the construction process.

- Q: What types of construction projects are steel frame formwork commonly used for?

- A wide range of construction projects necessitate the use of steel frame formwork for the construction of reinforced concrete structures. Some common examples of such projects include: 1. High-rise buildings: Steel frame formwork is frequently utilized in the construction of tall buildings due to its ability to provide a robust and long-lasting framework for the concrete structure. 2. Bridges: Steel frame formwork is also commonly employed in bridge construction as it can endure heavy loads and offer the necessary support for the concrete components. 3. Industrial structures: Factories, warehouses, and power plants often rely on steel frame formwork for their construction. This is because it enables the creation of large and intricate concrete structures, which are often necessary in industrial settings. 4. Infrastructure projects: Tunnels, dams, and water treatment plants are examples of infrastructure projects where steel frame formwork can be found. These projects typically involve the construction of sizable concrete structures that require a dependable and sturdy formwork system. 5. Residential buildings: Steel frame formwork is also utilized in the construction of residential buildings, particularly those with multiple floors. The steel frame ensures stability and safeguards the structural integrity of the building throughout the construction process and beyond. In summary, steel frame formwork is a versatile and widely utilized construction method that is commonly employed in various construction projects that require reinforced concrete structures.

- Q: How does steel frame formwork contribute to the overall efficiency of concrete placement and compaction?

- Steel frame formwork contributes to the overall efficiency of concrete placement and compaction in several ways. Firstly, steel frame formwork provides a stable and rigid structure that helps to maintain the shape and dimensions of the concrete elements being formed. This ensures accurate and precise placement of the concrete, resulting in a more efficient construction process. The steel frames are designed to withstand the pressure exerted by the wet concrete, preventing any deformation and maintaining the desired shape of the structure. Secondly, steel frame formwork allows for easy and quick assembly and disassembly. The frames are usually prefabricated and can be easily transported and assembled on-site. This saves time and labor, making the construction process more efficient. Additionally, steel frame formwork can be reused multiple times, further reducing the overall time and cost of the project. Furthermore, steel frame formwork provides a smooth and even surface for concrete compaction. The rigid structure of the steel frames prevents any bulging or sagging of the formwork, ensuring that the concrete is evenly distributed and compacted. This results in a higher quality finish and reduces the need for additional compaction efforts, saving time and resources. Lastly, steel frame formwork allows for easy access to the concrete during the placement and compaction process. The frames can be designed with openings and access points, providing convenient access for workers and equipment. This facilitates efficient pouring and compaction, as workers can easily reach all areas of the formwork, ensuring proper consolidation and eliminating the risk of voids or weak spots in the concrete. In conclusion, steel frame formwork significantly contributes to the overall efficiency of concrete placement and compaction. It provides stability, accuracy, reusability, and easy access, resulting in a more streamlined construction process and a higher quality finished product.

Send your message to us

STEEL FRAMED FORMWORK FOR CONSTRUCTIONS ALL THE WORLD

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords