Regular Spangle

Regular Spangle Related Searches

Regulating Valve Machine Spindles Column Splices Natural Slabs Radial Tyre Linear Shrinkage Traditional Wall Sconces Shrink Reduction Rubber Coupling Rising Stem Ball Valves Steel Screws Precision Slitting Rear Bumper Beam Common Weave Sticky Lubricant Roller Shutter Rubber Clamps Hand Held Sharpening Stone Non Expanded Polystyrene Reinforcing Retaining Wall Single Span Bridge Crane And Rigging Iron Sconces Automotive Rubber Seals Mesh Retaining Wall Protective Netting Flexible Netting Electric Sharpening Stone Translucent Polycarbonate Striped TarpaulinRegular Spangle Supplier & Manufacturer from China

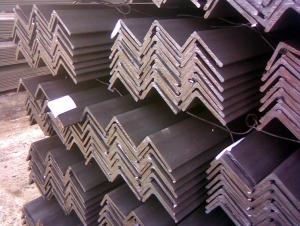

Regular Spangle is a collection of decorative metal products that are widely used for various purposes. These products are known for their eye-catching appearance and are commonly used in architectural applications, automotive designs, and home decor. They add a touch of elegance and sophistication to any surface they are applied to, making them a popular choice among designers and architects. The versatility of Regular Spangle allows it to be used in both indoor and outdoor settings, making it a practical choice for a wide range of projects.Regular Spangle is applied in various scenarios, such as in the construction of buildings, vehicles, and home furnishings. It is particularly popular in the automotive industry, where it is used to create a unique and stylish look for vehicles. In addition, it is used in interior design to add a touch of glamour to walls, ceilings, and furniture. The product's durability and resistance to weathering make it suitable for both residential and commercial applications, ensuring that it maintains its appearance over time.

Okorder.com is a leading wholesale supplier of Regular Spangle, offering a vast inventory of this product to cater to the needs of various industries. As a reliable source for high-quality metal products, Okorder.com ensures that customers receive the best possible products at competitive prices. By maintaining a large inventory, Okorder.com is able to provide prompt delivery and excellent customer service, making it a preferred choice for businesses looking to source Regular Spangle for their projects.

Hot Products