Steel Equal Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Equal Angle

1. Standards: GB,ASTM,BS,AISI,DIN,JIS

2. Length:6m,9m,12m

3. Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400; SS540.

4. Sizes:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Chemical data: %

C | Mn | S | P | Si |

0.14-0.22 | 0.30-0.65 | ≤0.050 | ≤0.045 | ≤0.30 |

Usage & Applications of Equal Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Products Advantages:

1. Convenient in construction and save much time and labor.

2. Light, good quality and reasonable price.

3. The shape and specification can be made by customer's requirement.

4. High mechanical strength.

5. Attractive in appearance and reasonable designs.

Packaging & Delivery of Equal Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

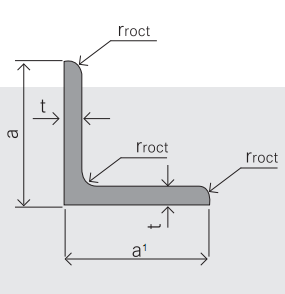

Images of Equal Angle

- Q: How are steel angles defined?

- Steel angles are defined based on the length of their legs, thickness, and their shape, which is typically L-shaped. These angles are commonly used in construction and engineering applications for structural support and framing purposes.

- Q: What is the maximum span for a steel angle?

- The maximum span for a steel angle depends on various factors such as the size, shape, and thickness of the angle, as well as the load it is expected to bear. Generally, larger and thicker steel angles have a greater maximum span. However, it is essential to consult structural engineering standards and codes, as well as professional engineers, to determine the specific maximum span for a particular steel angle in a given application. These experts will consider factors such as the material's yield strength, deflection limits, and safety factors to provide accurate guidelines for the maximum span.

- Q: How do steel angles differ from other structural shapes?

- Steel angles differ from other structural shapes in several ways. Firstly, steel angles have a distinct L-shaped cross-section, with two perpendicular flanges and a central web connecting them. This unique shape provides the angle with exceptional strength and load-bearing capacity, making it suitable for various structural applications. Secondly, steel angles are highly versatile and can be used in a wide range of construction projects. They can be easily welded, bolted, or screwed together to create complex structures such as frames, supports, and bracings. This flexibility makes them a preferred choice for engineers and architects. Moreover, steel angles are available in different sizes and thicknesses, allowing for customization based on specific project requirements. This variety in dimensions makes it easier to achieve the desired strength and stability in structural designs. Additionally, steel angles offer cost-effective solutions compared to some other structural shapes. Their efficient use of materials and manufacturing processes make them relatively affordable while still maintaining their durability and functionality. Lastly, steel angles can withstand significant loads and stresses, making them ideal for applications where structural integrity is crucial. Their ability to distribute weight evenly across the flanges and web ensures stability and prevents deformation under heavy loads. In summary, steel angles are unique structural shapes that provide strength, versatility, customizability, cost-effectiveness, and durability. These features make them an excellent choice for various construction projects, setting them apart from other structural shapes.

- Q: How are steel angles manufactured?

- Steel angles are typically manufactured through a process called hot rolling, where a steel billet is heated and passed through a series of rollers to give it the desired shape and dimensions. This process ensures that the angles have a consistent and uniform profile, making them suitable for various structural and construction applications.

- Q: What are the different methods of surface powder coating for steel angles?

- There are several methods of surface powder coating for steel angles. These methods are used to apply a protective and decorative layer of powder coating onto the steel surface. 1. Electrostatic Spraying: This is one of the most common methods used for powder coating steel angles. It involves using an electrostatic spray gun to apply the powder coating onto the surface. The powder particles are positively charged and are attracted to the grounded steel angle, resulting in a uniform and even coating. 2. Fluidized Bed: In this method, the steel angles are preheated and then dipped into a bed of fluidized powder particles. The heat from the steel causes the powder particles to melt and adhere to the surface, forming a smooth and durable coating. 3. Powder Coating Booth: This method involves placing the steel angles inside a powder coating booth. The booth is equipped with a powder spray gun that applies a fine mist of powder coating onto the surface. The angles are then cured in an oven to melt and bond the powder particles, creating a strong and long-lasting coating. 4. Electrostatic Fluidized Bed: This method combines the benefits of electrostatic spraying and fluidized bed techniques. The steel angles are preheated and then dipped into a bed of fluidized powder particles. An electrostatic charge is also applied to the powder particles, ensuring a more uniform and controlled coating. 5. Tribocharging: In this method, the powder coating is applied to the steel angles by frictional charging. The powder particles are passed through a tribocharging gun, which imparts a positive charge to the particles. The charged particles are then attracted to the grounded steel angle, resulting in a high-quality and consistent coating. Each of these methods has its own advantages and suitability for specific applications. The choice of the coating method depends on factors such as the desired finish, coating thickness, production volume, and cost considerations.

- Q: Are there any specific design considerations when using steel angles?

- Yes, there are several specific design considerations when using steel angles. These include determining the appropriate size and thickness of the angle to ensure structural stability and load-bearing capacity, considering the angle's orientation and connection details for proper installation, and accounting for any potential deflection or buckling issues that may arise due to the long and slender nature of angles. Additionally, it is important to consider the corrosion resistance of steel angles in certain environments and to select the appropriate coatings or treatments to mitigate this potential issue.

- Q: 100 x 100 x 10 equal angle steel, per meter weight?

- Angle steel is a kind of carbon structural steel for construction. It is a simple section steel, mainly used in the frame of metal component and workshop. In use, better weldability, plastic deformation and mechanical strength are required. The raw steel billet for producing angle steel is low carbon square billet, and the finished product angle iron is made by hot rolling, normalizing or hot rolling.

- Q: What is the maximum length of a steel angle available in the market?

- The market offers steel angles in varying lengths based on the supplier and the specific type of steel angle. Generally, lengths for steel angles range from 20 feet (6.1 meters) to 40 feet (12.2 meters). It is worth mentioning that these lengths are commonly found for standard steel angles, but there may be customized options that surpass these lengths for specific projects or applications. It is recommended to consult the supplier or manufacturer to ascertain the maximum length available for a particular steel angle.

- Q: Do steel angles require any special maintenance?

- Steel angles do not require any special maintenance, but proper care and attention can help prolong their lifespan. Regular cleaning to remove dirt, debris, and corrosive substances is recommended. It is also important to inspect the angles for any signs of rust, cracks, or damage, and address them promptly to prevent further deterioration. Applying a protective coating or paint can help prevent corrosion and extend the life of the steel angles. Overall, while steel angles are generally low-maintenance, regular inspections and maintenance practices can help ensure their optimal performance and longevity.

- Q: What is the typical thickness tolerance for steel angles?

- The typical thickness tolerance for steel angles can vary depending on the specific manufacturing standards and requirements. In general, the thickness tolerance for steel angles is typically within a range of +/- 0.005 to 0.010 inches (0.13 to 0.25 mm). However, it is important to note that this tolerance can also be influenced by the size and dimensions of the angle. Larger and thicker steel angles may have slightly looser tolerances compared to smaller and thinner angles. It is always recommended to consult the relevant industry standards or specifications to determine the specific thickness tolerance for a particular steel angle.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Middle East; Korea; Southeast Aisa |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 900,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Steel Equal Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords