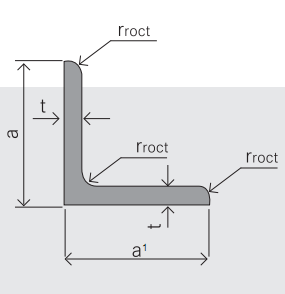

Equal Steel Angle

- Loading Port:

- Tianjin Port China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Equal Steel Angle

1. Standards: GB,ASTM,BS,AISI,DIN,JIS

2. Length:6m,9m,12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192,

SS400; SS540.

4. Sizes:

|

Sizes: 25mm-250mm | ||

|

a*t | ||

|

25*2.5-4.0 |

70*6.0-9.0 |

130*9.0-15 |

|

30*2.5-6.6 |

75*6.0-9.0 |

140*10-14 |

|

36*3.0-5.0 |

80*5.0-10 |

150*10-20 |

|

38*2.3-6.0 |

90*7.0-10 |

160*10-16 |

|

40*3.0-5.0 |

100*6.0-12 |

175*12-15 |

|

45*4.0-6.0 |

110*8.0-10 |

180*12-18 |

|

50*4.0-6.0 |

120*6.0-15 |

200*14-25 |

|

60*4.0-8.0 |

125*8.0-14 |

250*25 |

5. Material details:

|

Alloy No |

Grade |

Element (%) |

|||||

|

C |

Mn |

S |

P |

Si |

|||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045 |

≤0.3 |

|

|

|

|

|

|

|

|

|

|

|

Alloy No |

Grade |

Yielding strength point( Mpa) |

|||||

|

Thickness (mm) |

|||||||

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

||||

|

≥ |

|||||||

|

|

|

|

|

|

|

||

|

Q235 |

B |

235 |

225 |

215 |

205 |

||

|

Alloy No |

Grade |

Tensile strength (Mpa) |

Elongation after fracture (%) |

||||

|

Thickness (mm) |

|||||||

|

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

|||

|

≥ |

|||||||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

375--500 |

26 |

25 |

24 |

23 |

|

Usage & Applications of Equal Steel Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Steel Angle

1.Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2.With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: Where can you buy steel angles?

- Steel angles can be purchased at various places such as hardware stores, construction supply stores, metal fabrication shops, and online retailers specializing in metal products.

- Q: Are steel angles resistant to extreme weather conditions?

- Yes, steel angles are highly resistant to extreme weather conditions. They have excellent durability and can withstand harsh weather elements such as heavy rain, strong winds, and extreme temperatures without any significant damage or deterioration.

- Q: Are steel angles available in different alloys?

- Yes, steel angles are available in different alloys. Steel angles are typically made from carbon steel, which is the most common and versatile type of steel. However, there are also other alloys available for specific applications. For example, stainless steel angles are made from an alloy that contains chromium, which provides increased resistance to corrosion. Additionally, there are high-strength low-alloy (HSLA) steel angles that are made with a combination of carbon steel and small amounts of other elements like manganese, phosphorus, or sulfur to enhance their strength and durability. Overall, the availability of different alloys for steel angles allows for a wide range of applications and properties to meet specific needs in various industries.

- Q: Can steel angles be painted or coated after installation?

- After installation, it is possible to paint or coat steel angles for extra protection against corrosion and improved aesthetic appeal. Before painting or coating, it is crucial to cleanse and prepare the surface by eliminating any dirt, rust, or contaminants. This can be achieved by employing methods such as sandblasting, wire brushing, or utilizing chemical cleaners. Once the surface is clean and dry, a suitable primer can be administered to enhance adhesion and prevent corrosion. Following the drying of the primer, a final layer of paint or coating can be applied via a brush, roller, or spray. It is vital to select a paint or coating that is explicitly formulated for steel and provides the desired level of protection and durability.

- Q: How do you determine the appropriate size of steel angle for a specific application?

- To determine the appropriate size of steel angle for a specific application, factors such as the load it needs to bear, the length of the span, the type of material being supported, and any applicable building codes or regulations should be considered. Structural engineers or professionals with expertise in steel construction can perform calculations and analysis to determine the required size of steel angle based on these factors.

- Q: How do steel angles perform in high-temperature environments?

- Steel angles perform well in high-temperature environments due to their high melting point and excellent heat resistance. They retain their structural integrity and strength, making them a suitable choice for applications that require stability and durability in elevated temperatures.

- Q: Are steel angles resistant to termites and pests?

- Steel angles do not possess resistance against termites and pests. Due to their metallic composition, termites do not find steel angles appealing as a source of nourishment. Nevertheless, termites can still inflict harm on adjacent materials, like wood or insulation, that might exist within the structure where steel angles are utilized. It is crucial to guarantee that the overall construction is resistant to termites and implement necessary precautions to avert infestations.

- Q: Can steel angles be galvanized or coated for corrosion resistance?

- Steel angles have the capability to undergo galvanization or coating in order to achieve corrosion resistance. Galvanization is a widely utilized technique for safeguarding steel against corrosion, wherein a layer of zinc is applied to the surface. This method establishes a barrier between the steel and its surroundings, effectively preventing the formation of rust. Alternatively, steel angles can be coated with materials that possess corrosion-resistant properties, such as epoxy or powder coatings. These coatings serve as a protective shield, preventing moisture and other corrosive substances from reaching the steel surface. By employing galvanization or coatings, the lifespan of steel angles can be significantly extended, allowing them to maintain their structural integrity even in highly corrosive environments.

- Q: How do you prevent corrosion on steel angles?

- To prevent corrosion on steel angles, there are several preventive measures that can be taken: 1. Surface preparation: Before applying any protective coating, it is crucial to properly clean the steel angles to remove any dirt, rust, or other contaminants. This can be done through abrasive blasting, power tool cleaning, or chemical cleaning methods. 2. Protective coatings: Applying a protective coating on steel angles is one of the most effective ways to prevent corrosion. There are various types of coatings available, such as paint, epoxy, zinc-rich coatings, or galvanization. These coatings act as a barrier between the steel and the surrounding environment, preventing moisture and corrosive elements from coming into contact with the metal. 3. Cathodic protection: This method uses sacrificial metals or an impressed current to protect the steel angles from corrosion. Sacrificial metals, such as zinc or aluminum, are connected to the steel angles and corrode in place of the steel when exposed to corrosive elements. Impressed current systems use an external power source to provide a protective current to the steel, inhibiting corrosion. 4. Environmental control: Controlling the environment in which steel angles are installed can also help prevent corrosion. For example, reducing exposure to moisture, humidity, or corrosive chemicals can significantly extend the lifespan of the steel. This can be achieved by proper ventilation, ensuring proper drainage, or using protective coatings specifically designed for harsh environments. 5. Regular maintenance: Regular inspection and maintenance of steel angles are essential to identify any signs of corrosion early on. Any damaged or corroded areas should be repaired promptly to prevent further deterioration. Additionally, regular cleaning and reapplication of protective coatings can help maintain the integrity of the steel angles. By implementing a combination of these preventive measures, it is possible to significantly reduce the risk of corrosion on steel angles, prolong their lifespan, and maintain their structural integrity.

- Q: Can steel angles be used as reinforcing bars in concrete structures?

- Yes, steel angles can be used as reinforcing bars in concrete structures. Steel angles are commonly used for this purpose due to their strength and durability. They provide additional strength to the concrete, preventing cracks and increasing the overall stability of the structure. Steel angles are typically embedded in the concrete to provide reinforcement in areas where additional support is required, such as in beams, columns, and slabs. They are commonly used in construction projects such as bridges, buildings, and other concrete structures.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Middle East; Korea; Southeast Aisa |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 900,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Equal Steel Angle

- Loading Port:

- Tianjin Port China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords