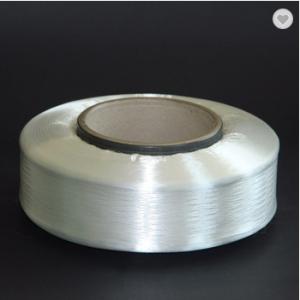

Eco-Friendly High Strength Fully Drawn Yarn FDY for Knitting Weaving Sewing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

Specification | 11-167dtex, 12-144F |

Production Capacity of FDY Yarn

The production capacity is 200,000 TONS per year for now and it will be of 500,000 per year after the erection of the second production line.

Application and suggestion:

1. The adhesive of two layers of sports shoe Upper material —FDY 50D/75D

2. Soft curtain, Zebra curtain, Roman curtain—FDY 75D/150D

3. Vertical blinds—FDY 250D

4. Filter net for air condition—FDY 30D/50D/75D/150D

5. Electromagnetic wire: PET-Glass fiber blended fiber—FDY 50D/75D

6. Garment lining cloth for suit, tie, hat, etc. —FDY 150D/50D/420D

7. Warp knitting fabric such as: Stiff mesh fabric, medical/food filter net, inner car decoration.

8. Top-grade eco-friendly filter material

9. Other applications: protective gloves, dust gauze, top-grade window screen, invisible screen, etc.

Advantage of Us:

Subsidiary of Stated-owned group, reliable and trustable

Industry leader in the PET chip and yarn fields

On time delivery and prompt response

Well-funded and accept different kinds of payment terms

Workshop

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- 1. Processing cotton yarn manufacturing methods are more complex, in general, there are two kinds of spinning methods, that is, carded spinning and combing spinning. (1) carded spinning process: with cotton → open cotton → carding → parallel → roving → spun yarn → post-processing → finished product inspection. (2) combing spinning process: with cotton → open cotton → carding → strip → strip → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q: What is the cheese yarn?

- Cheese yarn is the textile industry spinning mill production process of the winding process, from the process on the spinning frame or twisting machine down the pipe, according to the weaving factory, or knitting factory, or towel factory with the yarn After the process requirements

- Q: Textile waste silk (abandoned side yarn) what purpose ah?

- Textile industry more and more waste, need to use. The rapid development of chemical fiber industry, for the development of non-woven technology provides a wealth of raw materials, broaden the possibility of product development. Many traditional textiles for the final application, targeted poor

- Q: Is the price of oil and textile yarn?

- I was doing the fabric, the relevant situation can be considered a certain study, the final result is related but not the most important factor.

- Q: What is the process of towel in the textile?

- Electronic jacquard machine without the need to design a good program, including the flower and auxiliary needle control, dobby machine to design the program, if it is the most original machine to design a spike and shuttle steel plate, Organize the design of the pattern of the organization.

- Q: Will the following kind of yarn which fine? A32 support, B21 support

- The more the better the quality, the finer the yarn, the thinner the yarn weave, the more soft and comfortable the cloth is. The number of branches is fixed, so the greater the number of yarns, the finer the yarn. British count is not China's current legal indicators of yarn fineness, but still widely used in the enterprise, especially the cotton textile industry.

- Q: On the number of textile yarns

- Is often said that the British count, English: SIZE, all commonly used S to do short.

- Q: What is the reason why the yarn is spinning

- Spinning machine without insurance yarn, loom with a large circular machine, latitude and longitude knitting machine, the traditional shuttle weaving machine, etc.

- Q: Men's sweaters with what yarn?

- Needles: autumn and winter clothing generally choose some of the needle, the proposed 3-9 pin, yarn count: according to the number of yarn count should also be: 7-20S more appropriate. Color: autumn and winter men's best choice in the dark, wild color for the black, sapphire blue, Zhang Qing and other dark.

- Q: What is yarn support?

- Metric count (Nm) - At a given moisture regain, 1 gram of yarn length is a meter multiple, that is, 1 gram of heavy yarn is just 1 meter long, 1 (g) yarn, 1 gram heavy yarn Length of 200 meters long, the fineness of the yarn 200

Send your message to us

Eco-Friendly High Strength Fully Drawn Yarn FDY for Knitting Weaving Sewing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords